Gondor Cocoa Bean Grinding Machine Introduction

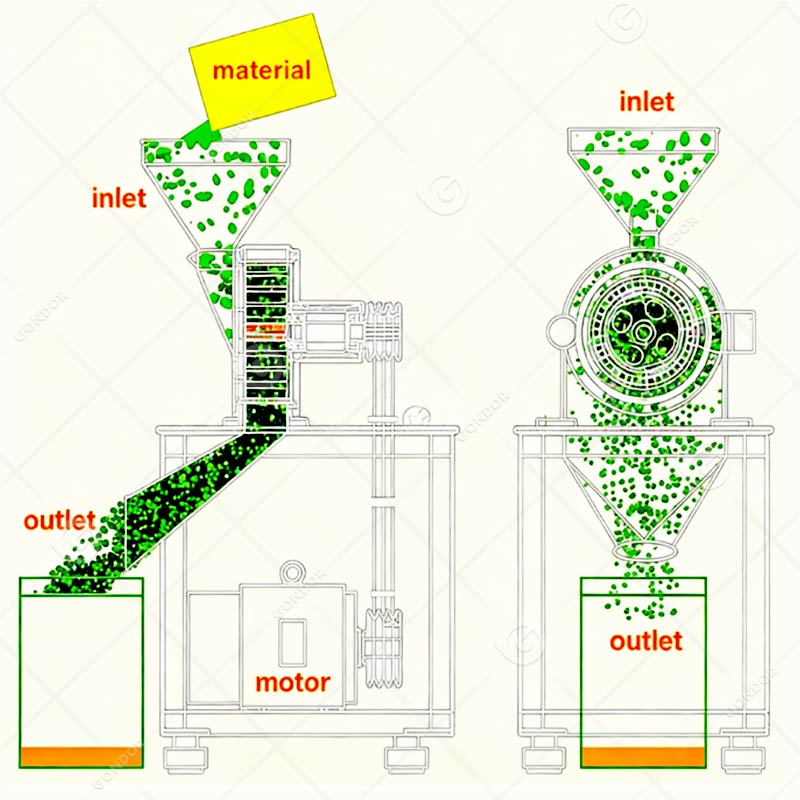

Gondor Machinery’s cocoa bean grinding machine utilizes advanced toothed disc technology, leveraging the high-speed relative movement between movable and fixed discs to deliver efficient impact and shearing, making it the ideal cocoa powder grinder machine for high-quality production. Strictly designed to GMP standards, this full stainless steel cocoa bean grinder is durable, পরিষ্কার করা সহজ, and features adjustable screen apertures for precise fineness control, providing a low-energy, dust-free, and professional cocoa grinding machine solution for your business.

Gondor Commercial Cocoa Powder Machine Models

Our range of cocoa bean grinding machines offers extensive processing capabilities, from compact lab-sized machines to high-volume industrial production lines. For further information, please contact us for a free consultation and detailed quote.

| মডেল | 15খ | 20খ | 30খ | 40খ | 50খ | 60খ | 80খ | 100খ |

| Capacity(kg/h) | 20-150 | 40-200 | 80-400 | 100-800 | 150-1000 | 250-1500 | 350-2000 | 500-3000 |

| Feed Particle Size

(মিমি) |

<10 | <10 | < 12 | < 15 | <18 | < 20 | < 25 | < 28 |

| Crushing Fineness

(জাল) |

20-120 | |||||||

| মোটর পাওয়ার

(kw) |

2.2 | 4 | 7.5 | 11 | 15 | 22 | 30 | 37 |

| স্পিন্ডেল গতি

(আরপিএম) |

6000 | 4500 | 3800 | 3400 | 3000 | 2800 | 2400 | 2000 |

| মাত্রা

(মিমি) |

550*400

*850 |

600*550

*1250 |

700*600

*1450 |

900*800

*1550 |

1050*850

*1750 |

1100*900

*1880 |

1200*950

*2000 |

1350*1000

*2100 |

| ওজন

(কেজি) |

150 | 280 | 340 | 450 | 600 | 900 | 1250 | 1580 |

What Is the Best Machine for Grinding Cocoa Beans into Powder?

For producing high-quality cocoa powder, a stainless steel universal toothed disc grinder is widely considered the industry standard. This equipment leverages high-speed impact and shearing forces to efficiently pulverize dried cocoa cakes into a uniform fine powder. Designed to meet strict GMP hygiene standards, it often features an optional water-cooling system to prevent cocoa butter from melting and sticking due to heat buildup.

By simply swapping screens of different apertures, operators can achieve precise control over particle fineness, making it a professional solution that balances efficiency, sanitation, and temperature management.

Industry Applications: Dedicated to Cocoa and Chocolate Processing

Our grinding machines are engineered as a core component for cocoa production lines, offering high hygiene standards and efficiency across the following sectors:

Other Applications of Cocoa Bean Grinding Machines

How to Prevent Cocoa Powder from Sticking in the Cocoa Bean Grinding Machine?

Keep Materials Dry

Ensure cocoa beans are thoroughly roasted and dried. High moisture content will turn the beans into a paste under pressure, causing heavy buildup inside the machine.

Control the Temperature

Cocoa butter melts at temperatures above 35°C. Use a grinder with a water-cooling system or grind in intervals to prevent the chamber from overheating and melting the fats.

Feed Uniformly

Avoid overloading the hopper. Use an automatic feeder to ensure a steady, consistent flow of material, which allows powder to exit through the screen quickly without accumulating.

Ensure Smooth Internal Surfaces

Use stainless steel (GMP standard) equipment with polished internal walls. The smoother the surface, the harder it is for powder to stick and the easier it is to clean.

Clean the Screen Regularly

If the screen mesh becomes clogged, heat will trap inside and worsen the sticking. Establishing a habit of regularly checking and cleaning the screen is key to preventing clogs.

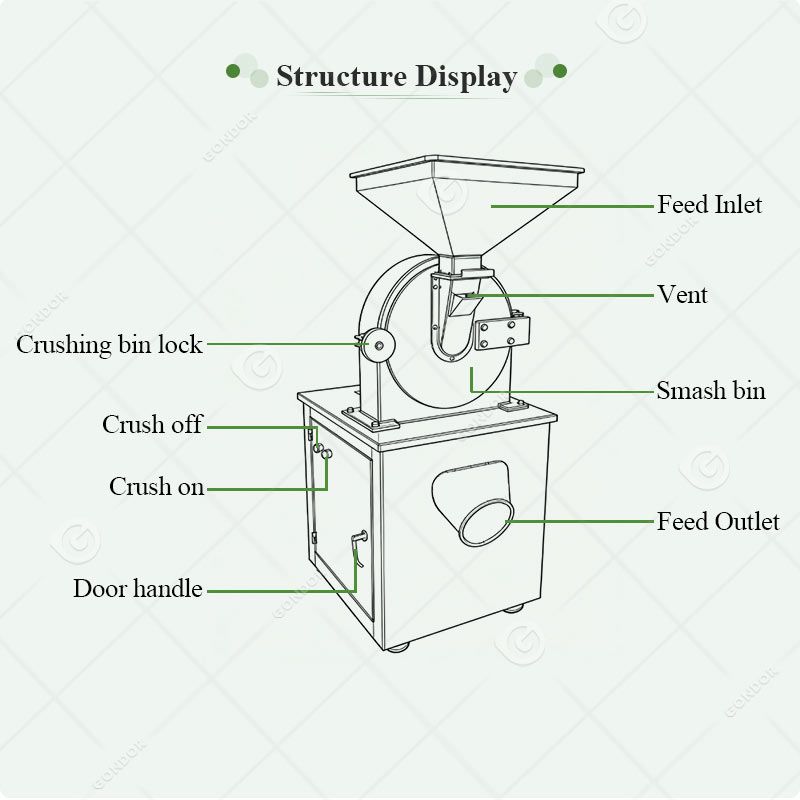

Gondor Cocoa Bean Grinding Machine Features

- কমপ্যাক্ট & শক্তি-দক্ষ: Engineered for stable performance with minimal noise and power consumption.

- Dust-Free Operation: High-speed processing with superior sealing to ensure a clean, dust-free working environment.

- সামঞ্জস্যযোগ্য সূক্ষ্মতা: Easily achieve desired particle sizes by simply swapping out screens of different apertures.

- Streamlined Cleaning: The mirror-polished interior prevents material buildup, ensuring rapid and thorough maintenance.