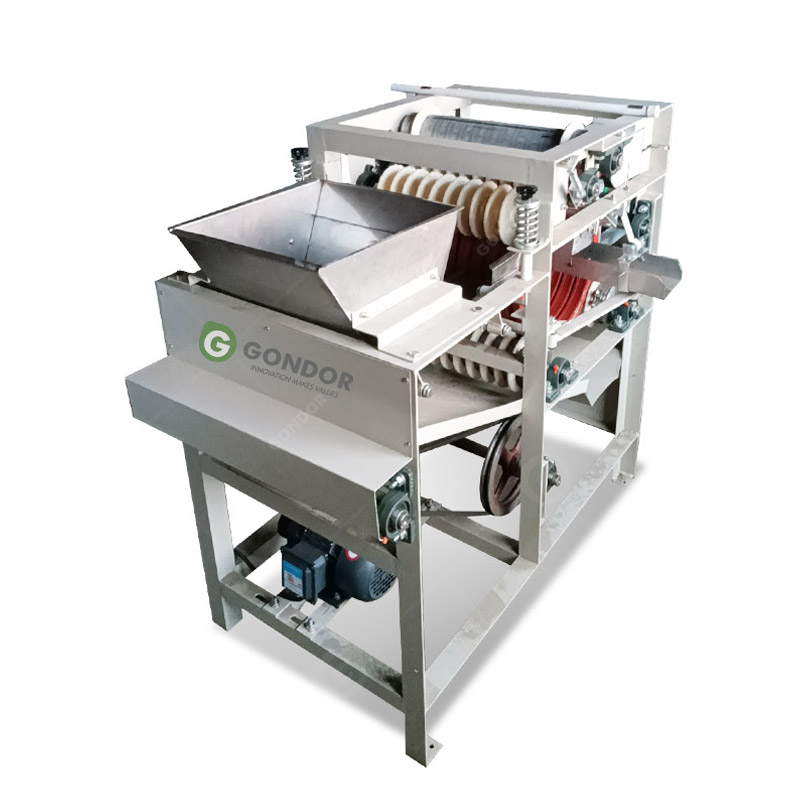

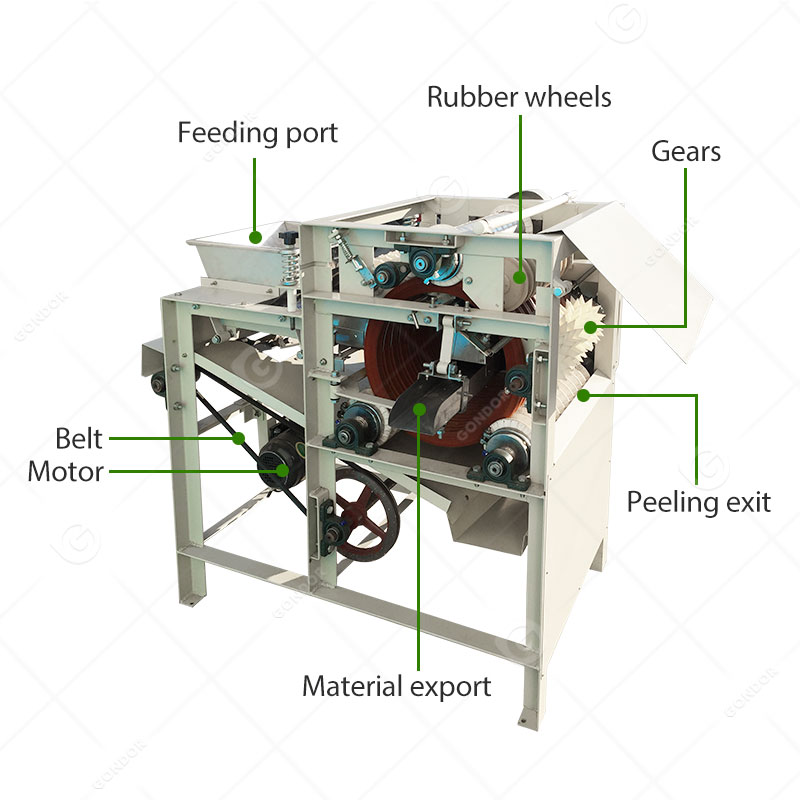

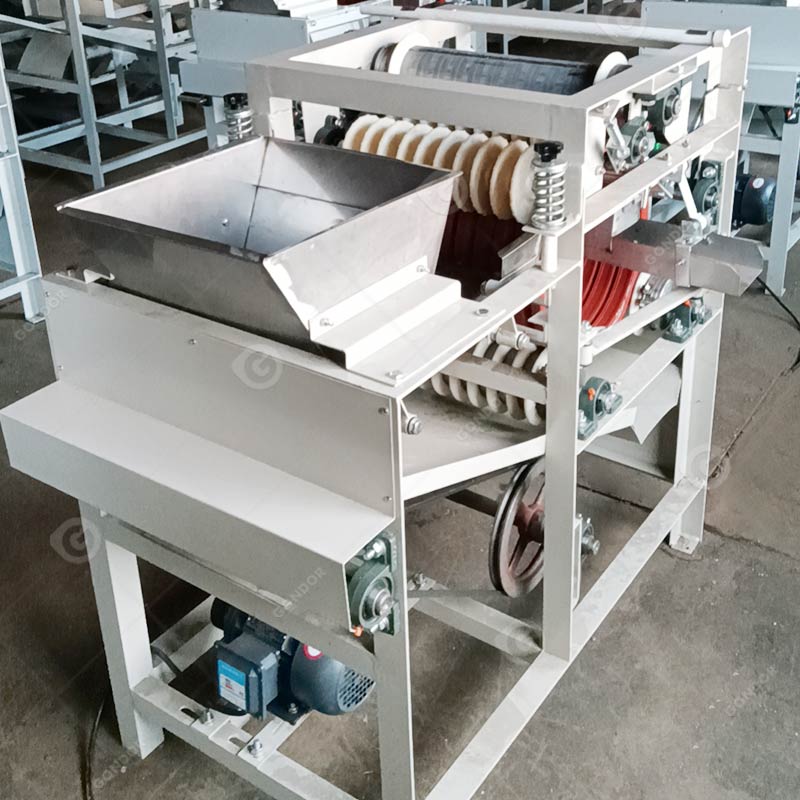

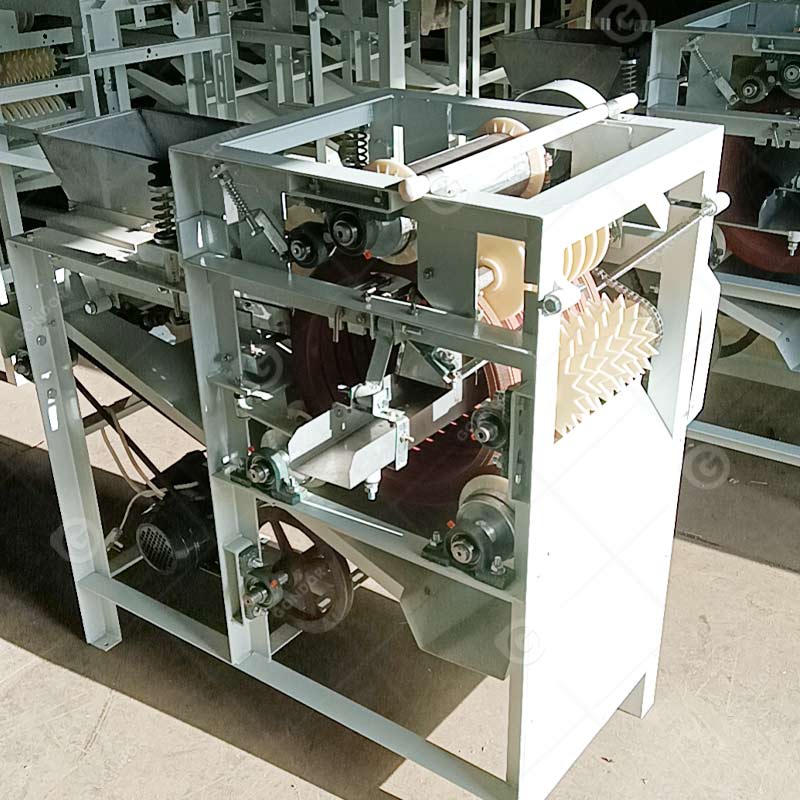

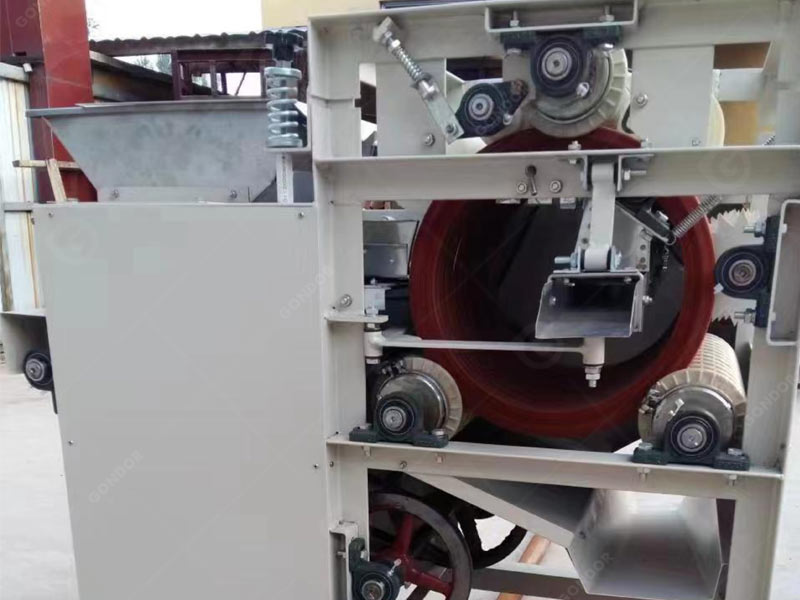

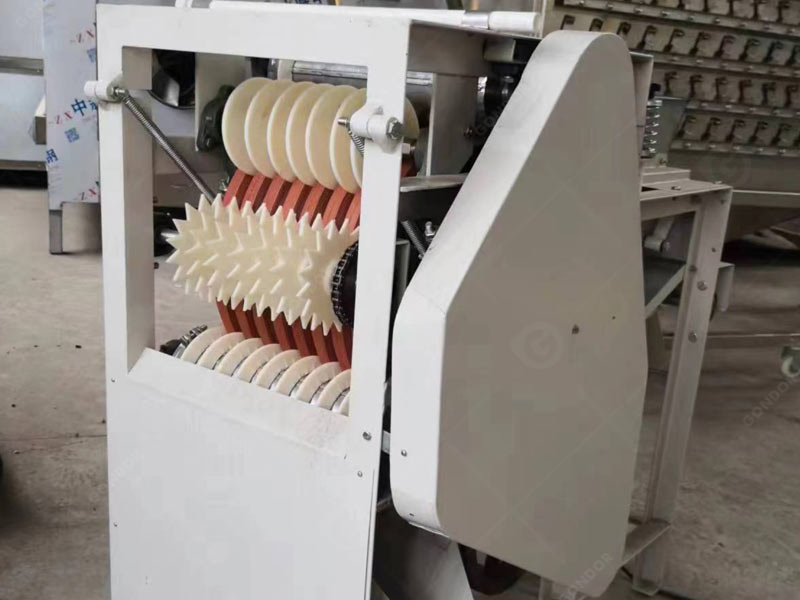

Almond Skin Removal Peeler Machine is a kind of equipment specially used to remove the outer skin of materials such as nuts and beans. When working, the raw materials are peeled by repeated friction between rubber wheels and rubber gears. Moreover, the uniqueness of this machine is that it has a high peeling rate. The peeled nuts and beans are white in color and the protein remains unchanged. At the same time, the skin and kernel are separated by themselves, with high efficiency and easy operation.

Gondor Wet Peel Machine

Gondor Dry Peanut Peeling Machine

| Model | Production efficiency(kg/h) | Power(kw) | Peeling ratio(%) | Crushing ratio

(%) |

Complete ratio

(%) |

Size(mm) |

| GD-PTPM-1 | 200 | 1.1 | 98% ±2 | 2-3 | 85-90 | 1180*850*1100 |

| GD-PTPM-2 | 150 | 0.75 | 98% ±2 | 2-3 | 85-90 | 1180*720*1100 |

Demand Areas for Gondor Almond Peeler

When producing various nut products, it can efficiently remove the outer skin of nuts, improve product quality and taste, and enhance the market competitiveness of enterprises.

Remove impurities and bad ingredients from bean skins, and improve the quality and nutritional value of bean products such as tofu, soybean milk, and bean skins.

Ensure the freshness, hygiene and safety of various nuts and beans, such as nut salad, soybean milk drinks, etc., and improve the taste and quality of dishes.

Make nut snacks and bean fast food. Wet peeling machine can quickly process a large amount of nuts and beans, improve production efficiency, reduce costs, and increase profit margins.

This device can remove impurities and defective components from raw materials, improve the purity of health products, and promote the development of the health product industry.

Sell various nuts and legumes health products. Processed products are more popular among consumers, increasing store sales and market competitiveness.

Powerful Functional Advantages of the Gondor Almond Skin Peeler

- It can quickly and effectively remove the skin of nuts and beans, and improve production efficiency.Efficient Peeling

- Wet treatment reduces damage to the kernel and also improves the quality of the product.Good Peeling Effect

- Semi-automatic equipment, easy to operate, easy to master, and does not require professional technicians.Simple Operation

- Using the adjustable spiral principle for peeling, it will not cause excessive damage to the internal nutritional components of the nuts.Gentle Treatment

- The whole machine is made of stainless steel, which is not easy to corrode and wear-resistant, and can ensure the long-term stable operation of the equipment.Sturdy and Durable

- Suitable for peeling various nuts and beans, such as almonds, peanuts, soybeans, etc. Different products can achieve the best peeling effect by adjusting parameters.Wide Applicability

- Whether it is a small processing plant or a large production enterprise, you can choose equipment of appropriate specifications according to your production needs.Production of Different Scales

Usage Process of Gondor Almond Skin Removal Machine

Gondor Almond Skin Removal Peeler Machine – Quality Choice

Choose Gondor almond skin removal peeler machine to start your efficient processing journey. It has excellent peeling effect, easy operation, safety and hygiene. It helps your production and improves product quality. Investing in our almond skin removal machine is investing in a successful future. Come and buy it, let us create a better tomorrow together!