Gondor Automatic Donut Maker Machine

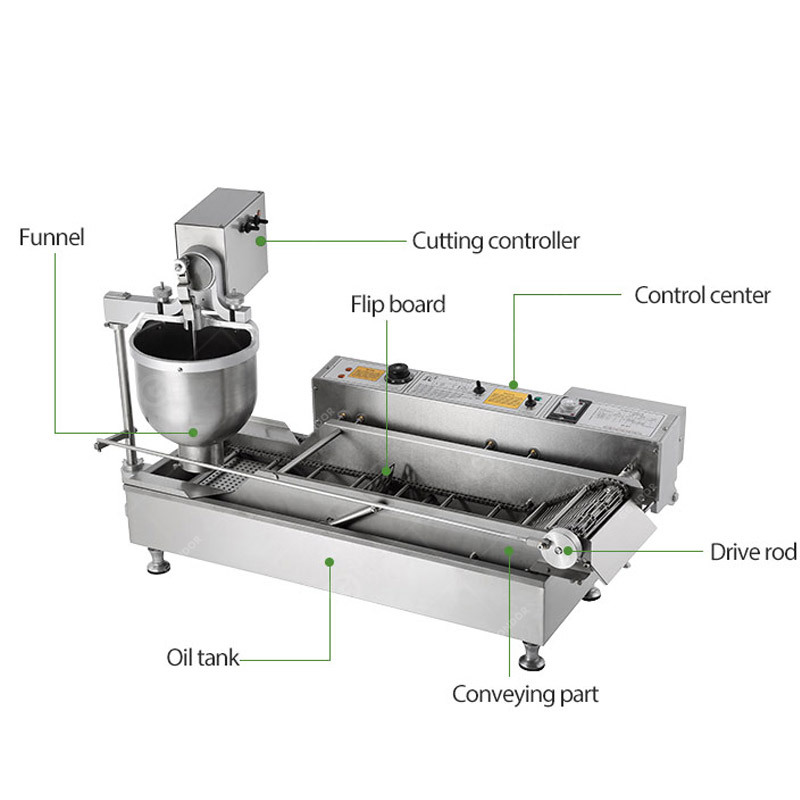

Automatic commercial donut maker machine is an efficient food processing equipment. It uses automatic temperature and speed control technology to quickly make delicious donuts. Moreover, the machine has configurations such as automatic temperature control, ultra-high temperature protection system, chain crawler conveyor, and donut thickness and size adjustment. Besides, Gondor automatic donut maker machine has high production efficiency, automatic molding, and automatic advancement, making it the best choice for various franchise stores and food factories.

| Model | Size | Net weight | Voltage | Power | heating method | Die size |

| SK-T1 | 1050*540*670mm | 43kg | 220v | 6kw | Electric heating | 20mm/36mm/40mm |

| NP-1 | 1100*600*460mm | 48kg | 110v/220v/38v | 6kw | Electric heating | 20mm/36mm/40mm |

| T-100 | 1200*550*720mm | 48kg | 220v | 6kw | Electric heating | 20mm/36mm/40mm |

| T-100A | 1300*600*840mm | 65kg | 220v | 6kw | Electric integraion | 20mm/36mm/40mm |

| T-100B | 1300*600*840mm | 61kg | 220v | 50w | Gas heating | 20mm/36mm/40mm |

| T-100C | 1300*700*1100mm | 75kg | 220v | 50w | Gas heating | 20mm/36mm/40mm |

Main Application Industries of Gondor Automatic Donut Maker

Baking Food Factory

Mass production of donuts of various flavors, supplying to supermarkets, convenience stores, bakeries and other sales channels.

Pastry Processing Factory

Donuts with different flavors and decorations can be made to enrich the product line and meet the needs of different customers.

Frozen Food Factory

Produce frozen donuts, which are convenient for storage and transportation, and also meet the needs of consumers’ fast-paced life.

Coffee Shop and Dessert Shop

Make fresh donuts on site and provide them to customers with coffee or other drinks to increase the attractiveness and sales of the store.

Large Supermarket

Consumers can buy freshly baked donuts to increase the fun of shopping. At the same time, supermarkets can also sell packaged donuts.

Specialty Store

Open a donut specialty store to attract donut lovers to buy by providing donuts of various flavors and characteristics.

Theme Parks and Amusement Parks

Sell donuts in restaurants or snack stands in the park to increase visitor satisfaction and return rate.

Cafes and Teahouses

As a leisure place, provide donuts as a snack to go with drinks. Customers can enjoy donuts and drinks in a comfortable environment and enjoy a leisurely time.

Advantages of Gondor Automatic Donut Maker Machine

- Automatic temperature control, automatic flipping, automatic frying, and automatic out of the pot.High Degree of Automation

- According to different product requirements and raw material characteristics, the frying temperature and time can be controlled.Temperature and Time Control

- The machine can mold the dough into the shape of donuts in a short time to ensure the consistency and beauty of the product.Rapid Molding

- The donut machine can produce donuts of various shapes, flavors and sizes to meet the needs and preferences of different consumers.Multiple Shapes and Sizes

- All stainless steel 304 shell, 360° fully waterproof workbench, low maintenance cost and long service life.Sturdy and Durable

- Customers can choose the model, output and mold of the donut machine according to production needs.Diverse Choices

High-Efficiency Processes

Complete Production Line Solution

To achieve integrated operations from production to packaging, this equipment seamlessly interfaces with the following systems:

Post-Processing Equipment:

- Chocolate Enrobing Machine: Automates glazing, coating, and decorating with sugar sprinkles.

- Cooling Tunnel: Rapidly cools and sets coatings to ensure quality.

- Pillow Packaging Machine: Automatically bags, seals, and codes single/multiple products.

Facility Layout Recommendations:

- Individual Machine Footprint: 3.2m × 1.8m (including operator space).

- Standard Production Line (including coating and packaging): Reserve an 8m × 5m area.

Automatic Commercial Donut Maker Machine – Start a Sweet Journey

Gondor’s automatic commercial donut maker machine is efficient and convenient, making delicious donuts easily. Precise temperature control and uniform heating ensure that every donut is perfect. Simple operation, saving time and effort, is a good helper for you to start a business or enrich your food choices. Choose our automatic donut maker and start a new journey of sweet business.