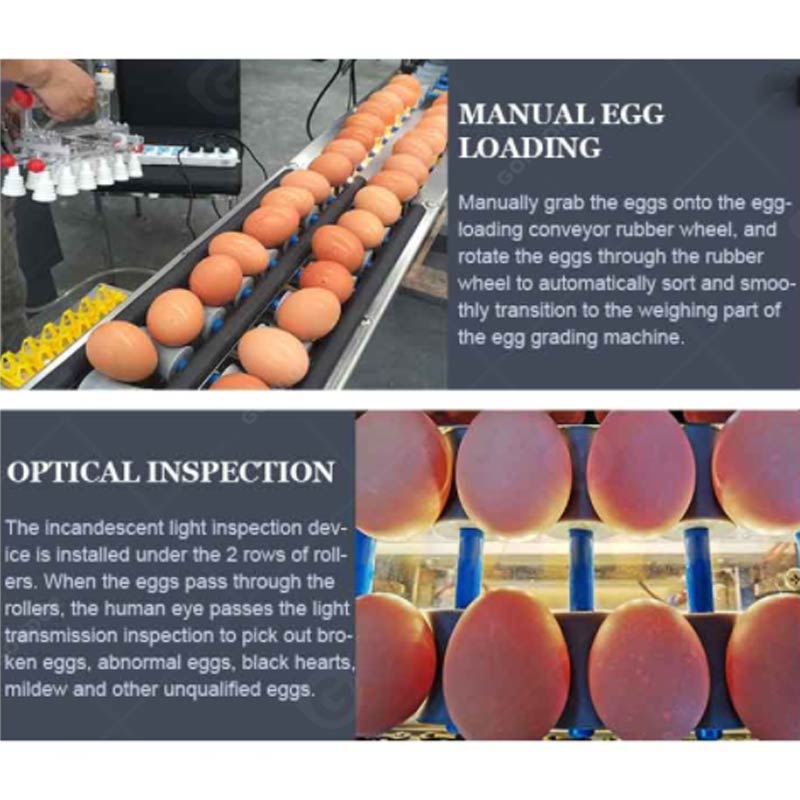

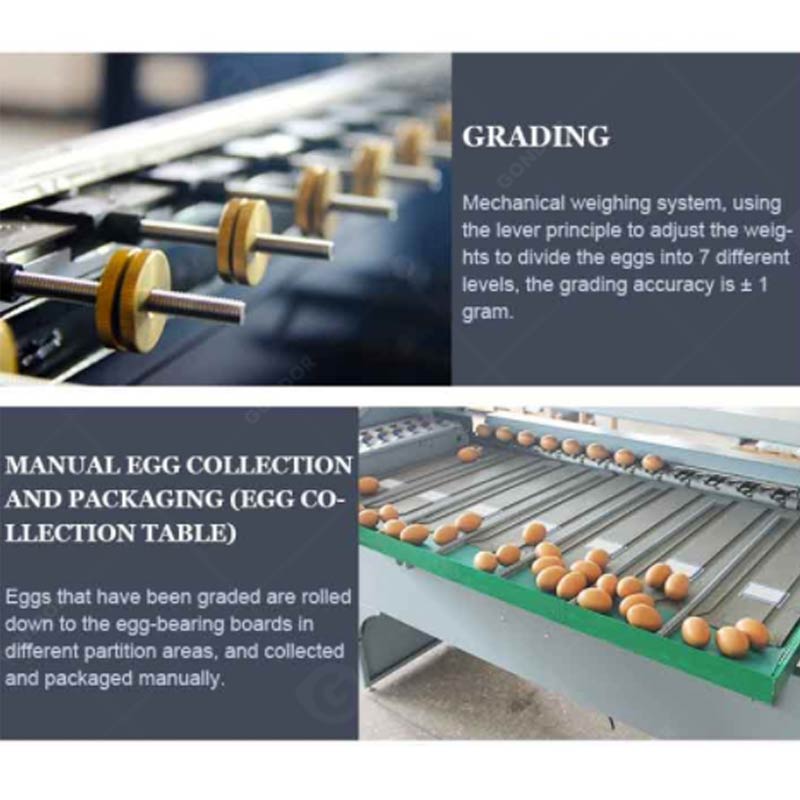

Automatic egg sorting grading machine is an efficient and reliable automated piece of equipment that can automatically distribute eggs to different collection areas based on their weight. The equipment adopts a stainless steel frame structure, which offers the advantages of being lightweight, strong, and aesthetically pleasing. Moreover, its spare parts have good interchangeability, ensuring the stability of the equipment. By utilizing the lever weighing and knife-type conveying principles, it guarantees accurate weighing and easy adjustment, while also preventing egg breakage. Additionally, the equipment can be optionally equipped with an optical inspection device to detect broken or unqualified eggs. As a result, the eggs are automatically sorted, weighed, and graded, and finally collected and packaged manually, thus achieving an efficient grading and packaging process.

Gondor Automatic Egg Grading Line

|

Product name

|

Egg grading machine

|

|

Model

|

GD101B

|

|

Material

|

304 SS

|

|

Speed

|

4000pieces/h

|

|

Accuracy

|

g

|

|

Grade

|

7

|

|

Power

|

0.218kw

|

|

Voltage

|

220V, 50Hz

|

|

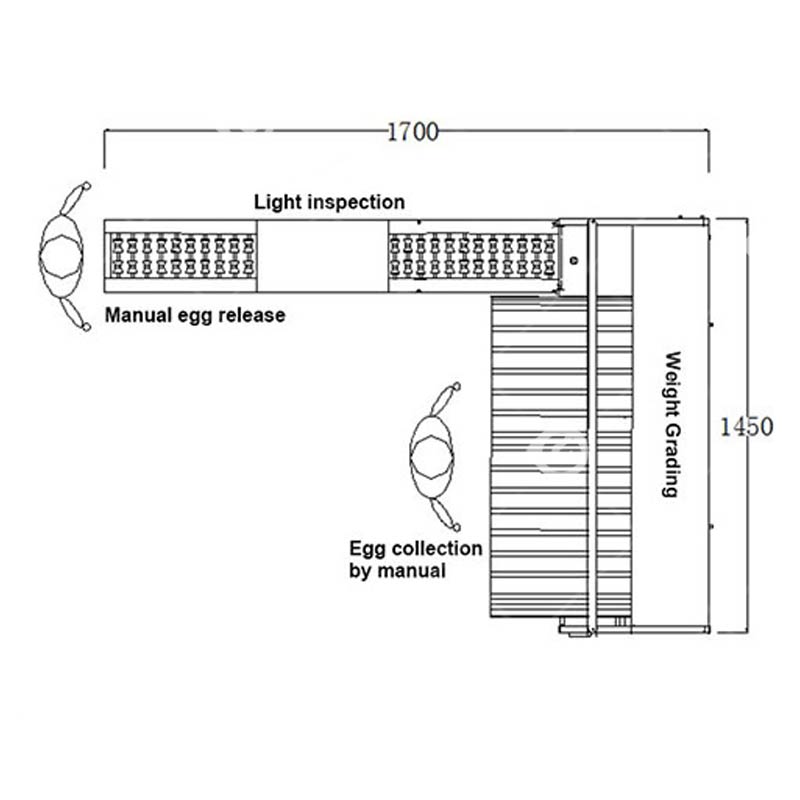

Dimension

|

170*145*100cm

|

|

Function

|

Manual egg laying, LED light inspection, weight grading

|

Different Application Fields of Gondor Automatic Egg Grading Machine

Egg grading machines are widely used in many industries to help improve production efficiency and ensure product quality. The following are the applications of this equipment in different fields and their related content:

Significant Working Advantages of the Gondor Egg Sorting Machine

Gondor Egg Grading Machine – Enhance Efficiency and Quality

The Gondor automatic fault egg sorting machine is the ideal solution to improve your egg processing efficiency. With its advanced stainless steel frame design, the equipment is not only durable but also aesthetically pleasing, ensuring stable, long-term operation. Moreover, its precise lever weighing system and knife-type conveying method allow for quick and accurate egg grading while minimizing the risk of damage. Additionally, the optional optical inspection device provides timely screening of unqualified products, ensuring higher quality control. The fully automated grading and packaging process significantly increases efficiency and reduces labor costs. Furthermore, the equipment’s spare parts are easy to replace, making maintenance simple and convenient. By choosing Gondor, you are opting for an efficient, reliable, and user-friendly egg grading solution.