In today’s era of pursuing high efficiency and automatic production, the flat labeling machine has become an important automation equipment in food, medicine, daily chemical, electronics, logistics, and other industries. It is specially designed for all kinds of flat or slightly curved products. It supports high-speed labeling, intelligent control, and multi-size compatibility, and helps enterprises achieve the dual goals of production automation and cost control.

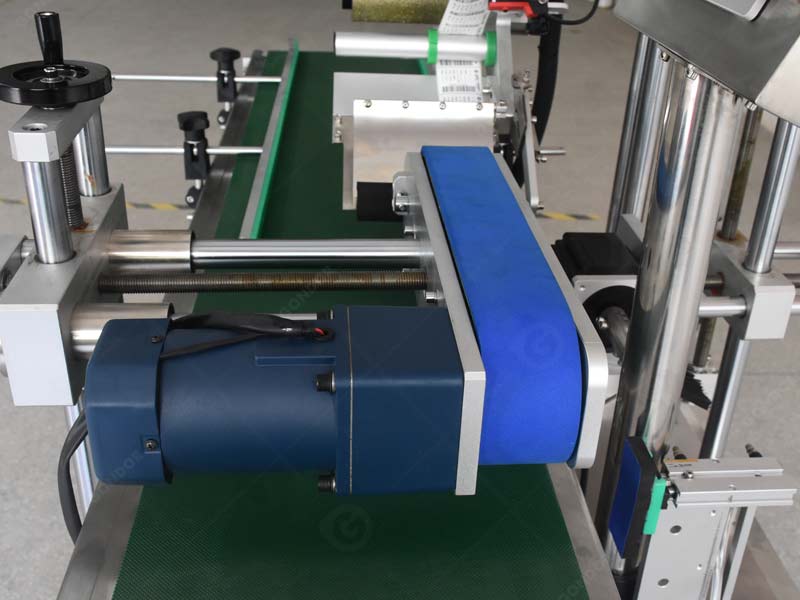

| Machine size(LxWxH) | 2000x800x1600mm |

| Speed | 60-150 Pcs/min |

| Suitable diameter of bottles | ≤180mm |

| Label height | 15-200mm |

| Label length | 25-300mm |

| Label accuracy | ≥1% |

| inner diameter of the label roll | 76mm |

| Label roll outer diameter | 350mm |

| Voltage | 220V 1.5KW 50/60Hz |

| Net weight | 180kg |

| Package size(LxWxH) | 2100x850x1600mm |

Wide Application Range of Flat Labeling Machine

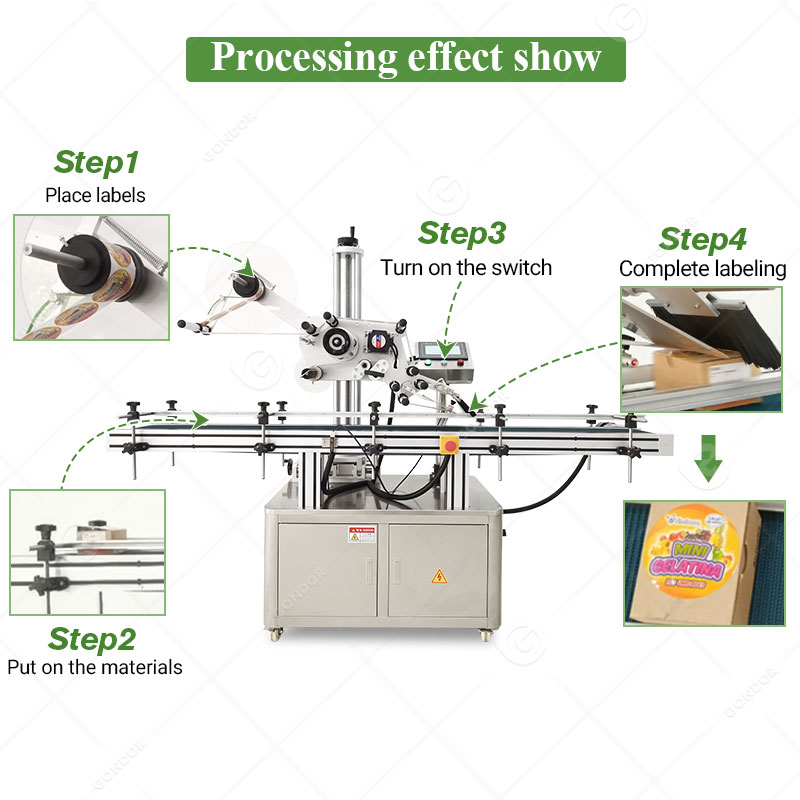

This machine is suitable for labeling various flat products, including but not limited to:

- Plastic bags, books, folders, cartons, cartons.

- Cosmetic packaging, food packaging box, electronic product shell, and metal plate.

- Applicable product width range: 30 mm~300 mm.

- Label supports customized length to meet the personalized needs of different brands.

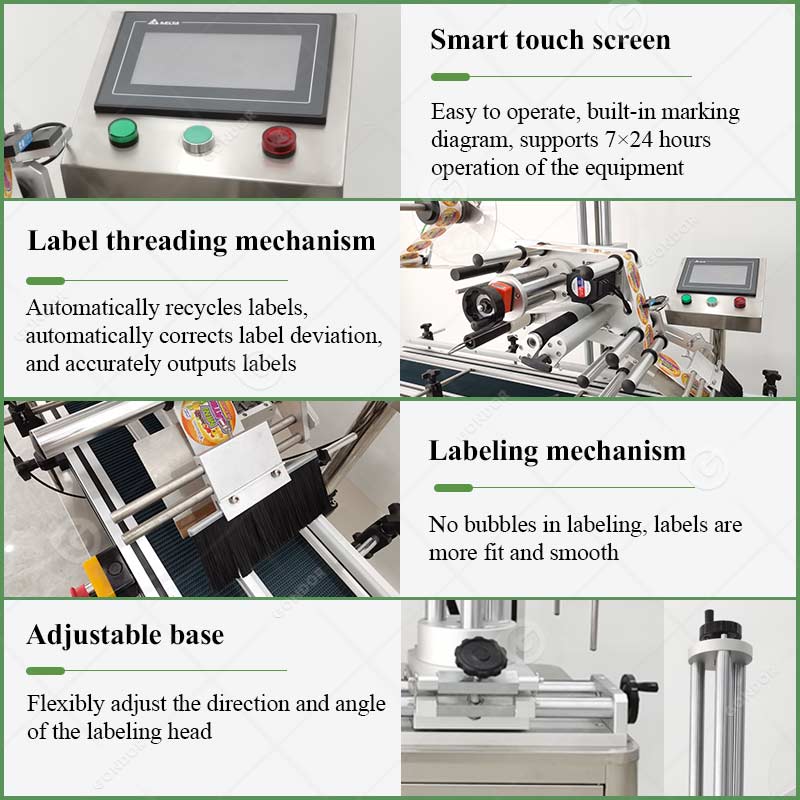

Efficient Performance Advantages of the Automatic Flat Labeling Machine

Optional Accessories

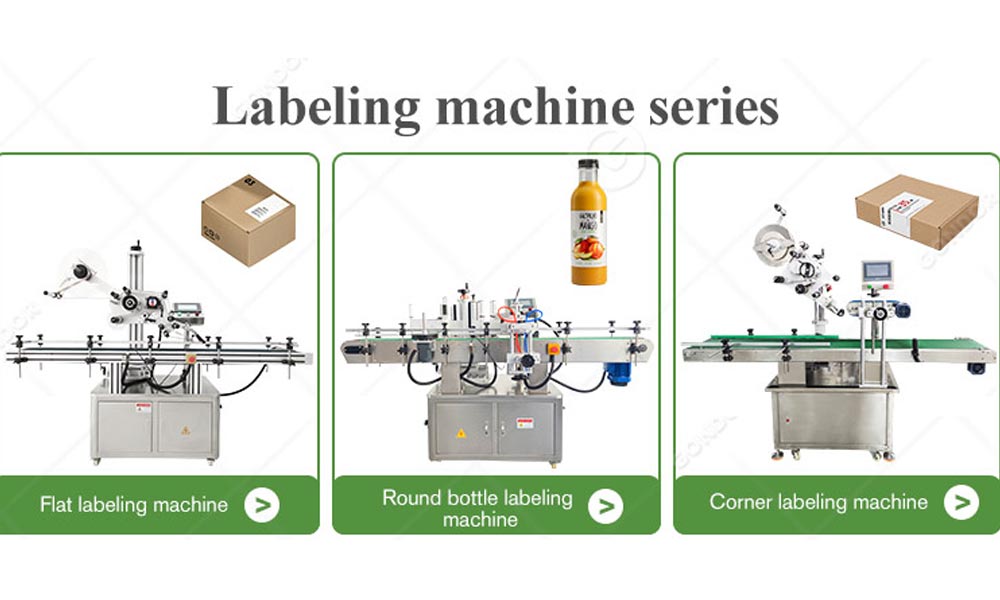

Related Machines

To meet the labeling requirements of more products, we also provide the following labeling equipment:

- Round Bottle Labeling Machine: It is suitable for single-sided or double-sided labeling of various round bottles, widely used in beverage, daily chemical, medicine and other industries, with accurate labeling and fast speed, which can effectively improve packaging efficiency and product aesthetics.

- Corner Labeling Machine: Specially designed for corner labeling of box products, which can achieve 90 or 180 corner coverage, and the labels are closely attached, which is suitable for the standardization requirements of packaging labels in medicine, electronics, food, and other industries.