High-Efficiency Automatic Ice Cream Waffle Cone Baking Production Line

Explore a new generation of automatic ice cream waffle cone baking production line, designed for global customers! Our ice cream cone production line combines high automation and long service life, equipped with intelligent PLC control system, and produces tens of thousands of cones with zero pressure every day. Whether it’s a crispy Cone, an egg Roll or a Wafer Bowl, one machine can adapt to all. The equipment adopts wear-resistant components, and the maintenance cost is extremely low, which helps you to reduce costs and increase efficiency continuously!

| Name | Power | Voltage(v) | Weight(kg) | Size(mm) | Capacity |

| Heating mixing drum | 4 | 220/380 | 220 | 800*1650 | 200L |

| Ice cream cone baking machine | 3.37 | 220/380 | 4300 | 7600*2100*2000 | 3500-4000pcs/h |

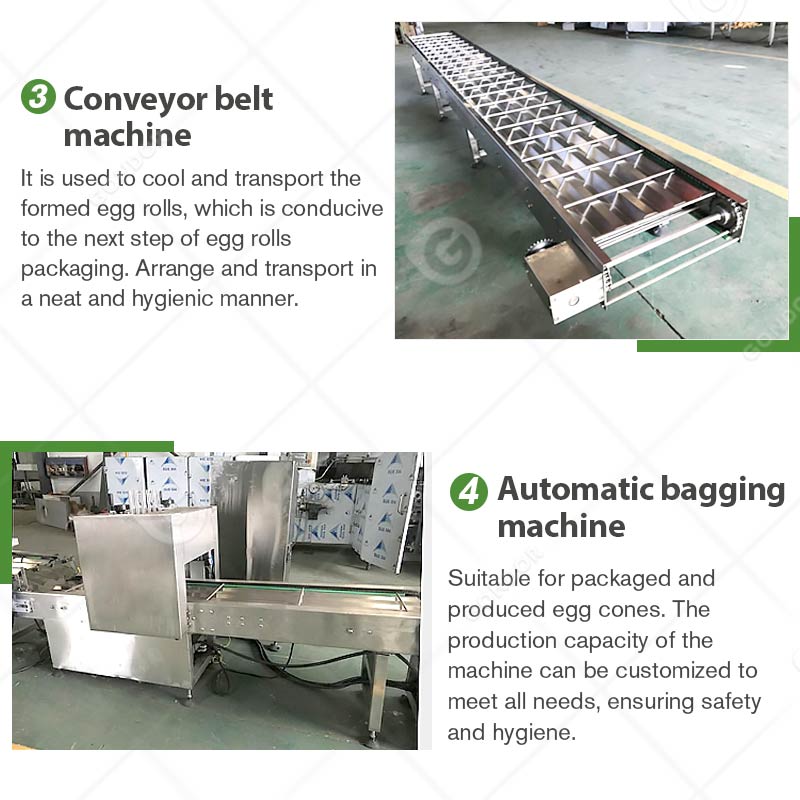

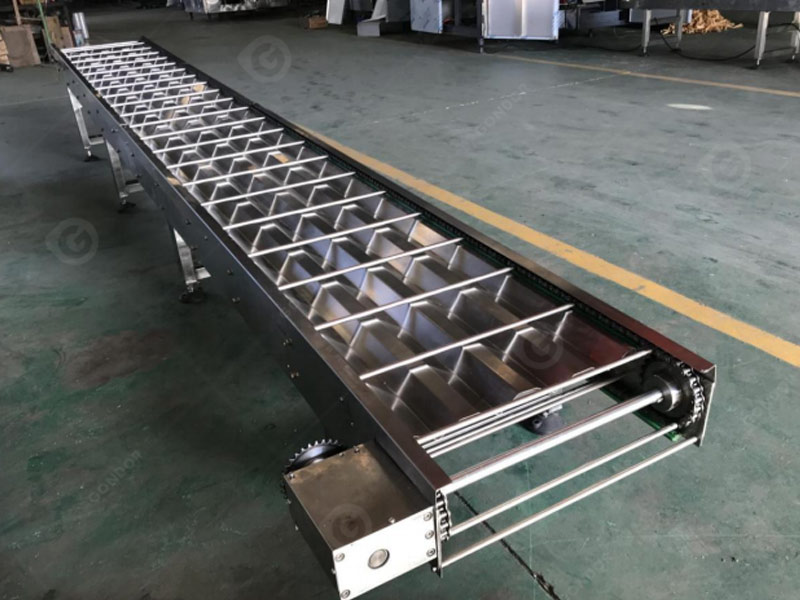

| Conveyor belt machine | 0.75 | 220/380 | 250 | 5000*800*500 | 200/h |

| Automatic bagging machine | 0.75 | 220/380 | 200 | 2400*1100*1200 | 5000pcs/h |

Application Market Scope of Ice Cream Cone Production Line

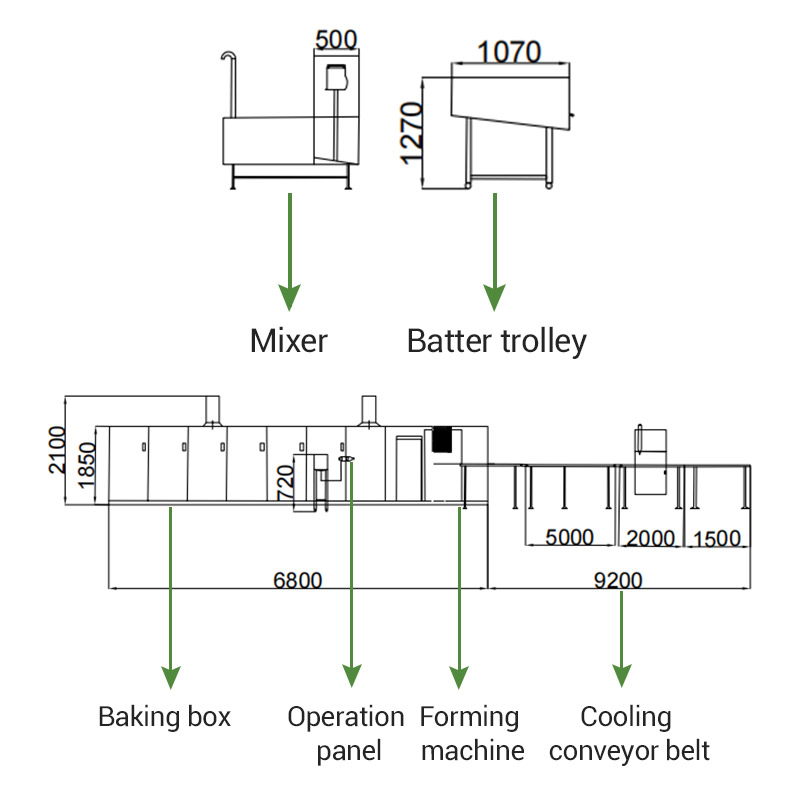

Product Details of Gondor Waffle Cone Production Line

- Tilted mixer, quickly and quickly mixes water, flour, sugar, oil and other raw materials in proportion, automatic timing system, simple operation, stable performance.Heating Mixing Bucket

- Shape the mixed dough, bake it, roll it into egg rolls and send it out. The whole product is completed in one line, which is efficient, time-saving and labor-saving.Egg Cone Production Line

- Used to cool and convey the formed egg rolls, which is conducive to the next step of egg roll packaging. Arrange and convey, neat and hygienic.Cooling Conveyor Belt

- Suitable for packaging produced egg cones. The machine output can be customized to meet all needs, safe and hygienic.Fully Automatic Bagging Machine

Main Features of Automatic Waffle Cone Baking Line

High Degree of Automation

Adopting advanced automation technology reduces manual operation steps, improves production efficiency, and reduces labor intensity.

High-Speed Production Capacity

The production line is compactly designed and can produce a large number of ice cream cones in a short time to meet the high market demand for ice cream cones.

Rich Flavors

A variety of flavors and ingredients can be added, such as chocolate, vanilla, strawberry, etc., to produce ice cream cones with a variety of flavors, enrich product types and improve market competitiveness.

Temperature And Time Control

Equipped with PLC control, it can accurately control the baking temperature and time according to different product requirements.

Diverse Product Specifications

Ice cream cones of different specifications and shapes can be produced to meet different market needs.

Customizable

Different ice cream cones require different machines to make, and we will make suitable machines according to customer needs.

Automatic Ice Cream Waffle Cone Baking Production Line – Gondor Group Manufacturer

Dear friends, choose Gondor automatic ice cream waffle cone baking production line to start a delicious and wealthy journey. Our production line has a high degree of automation and excellent production efficiency, and can produce crispy and delicious cones. High-quality equipment and thoughtful service will help your business. Investing in the Gondor automatic waffle cone baking line is a successful investment. Come join us and create a better future together!