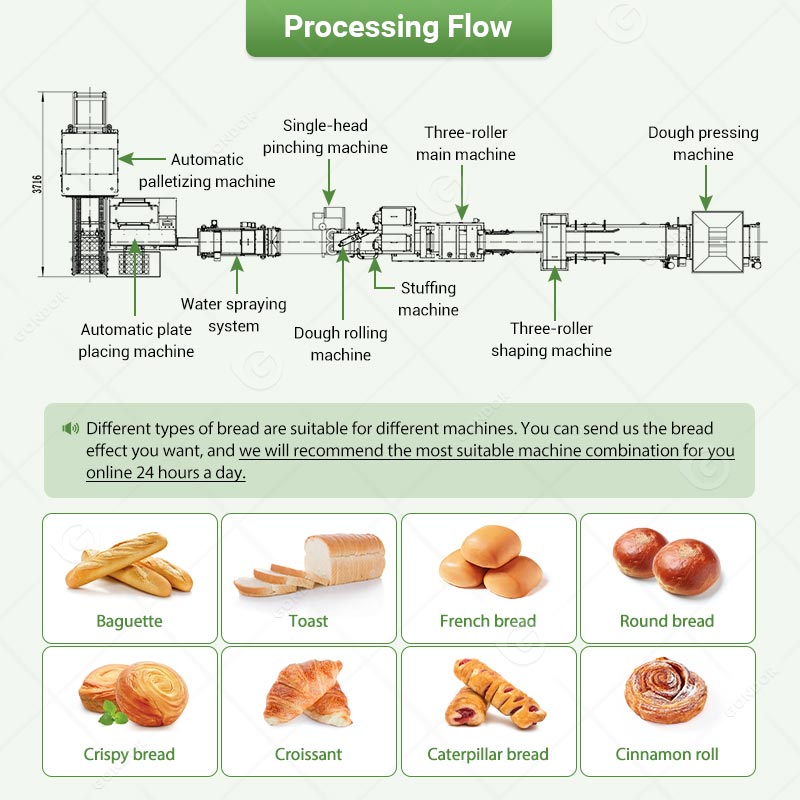

The multifunctional bread production line is an advanced automated system designed for large-scale bread production. It handles every step—from dough making and shaping to stuffing, baking, and packaging—with precision and efficiency, ensuring consistent quality. Equipped with an intelligent PLC control system, it supports modular design and customization, adapting to various bread types like toast, baguettes, and whole wheat. Operating efficiently, it reduces labor costs and boosts production capacity, making it ideal for bakeries, central kitchens, and food processing companies.

Product name | Product Parameters |

| Fully automatic noodle pressing machine | Noodle pressing width <500mm Voltage/power: 380V/3.0kw Dimensions: 1300*1000*1400mm Weight: about 450kg |

Noodle strip splitting and shaping machine | Roller width 320mm Voltage/power: 380V/1.5kw Dimensions: 3300*700*1300mm Weight: about 100kg |

| Three-pass rolling machine | Roller width 300-500mm Voltage/power 380V/3.2kw Dimensions 4100*770*1500mm Weight about 400kg |

Dough strip slitting machine | Voltage/power 380V/220V/0.2kw Dimensions 1250*920*700mm Weight about 70kg |

| Dough Rolling Machine | Voltage/power 220V/0.32kw Dimensions 1750*920*940mm Weight about 90kg |

Filling machine | Diameter of feeding port: 6-38mm (customizable) Voltage/power 220V/0.75kw Dimensions 1000*410*1320mm horizontal Dimensions 500*400*1430mm vertical Weight about 90kg |

| Split cutting table (servo) | Production capacity 50-180 pieces/minute Voltage/power 220V/380V/0.75kw Dimensions 1200*620*1300 Weight about 180kg |

Flower pinching machine | Production capacity 2000-6000 pieces/hour Voltage/power 220V/0.75kw Dimensions 1350*750*1200mm Weight about 180kg |

| Tray machine (servo) | Production capacity 1200-12000 pieces/hour Voltage/power 220V/380V/0.76kw Dimensions 3000*1100*1300mm Weight about 180kg |

Application Market Scope of Industrial Bread Production Line

With its high efficiency, flexibility, and intelligence, the multifunctional bread production line is widely used across various industries and scenarios, effectively meeting the diverse needs of different markets. Whether for large-scale industrial production or customized, small-batch requirements, this production line significantly boosts production capacity and reduces operating costs. As a result, it has become an indispensable and efficient solution for the food industry. The following highlights its main application markets:

Meet the needs of mass production and ensure product consistency and high quality.

Support the production of multiple types of products and improve market competitiveness.

Efficiently produce standardized products to provide stable supply to stores.

Quickly and efficiently produce a variety of bread to meet logistics and distribution needs.

Support customized production and provide supermarkets with rich and diverse bread products.

Meet the needs of the international market and provide high-quality and diversified bread products.

Produce bread that conforms to health concepts, such as whole wheat, sugar-free and other special breads.

Used for food technology research and development, production technology research and experimental teaching.

Significant Working Advantages of the Gondor Automatic Bread Line

The multifunctional automatic bread line has demonstrated remarkable competitiveness in food production thanks to its high efficiency, intelligence, and flexibility. By leveraging advanced technology and careful design, it not only optimizes the production process but also significantly reduces costs while improving product quality and consistency. The following are its main working advantages:

Choose Gondor Bread Production Line – Seize Market Opportunities

With its high efficiency, intelligence, and flexibility, the Gondor bread production line offers a complete solution for large-scale bread production. From dough making to baking and packaging, every step is executed with precision and efficiency, ensuring consistent product quality. Moreover, the equipment features a modular design and an intelligent PLC control system, supporting the production of various bread types to meet personalized customer needs. At the same time, it significantly reduces labor costs and boosts production capacity. Whether for bakeries, central kitchens, or food processing companies, this production line helps optimize processes and achieve greater economic benefits.

Choosing Gondor means choosing efficiency and quality! Order now or fill out the inquiry box below to learn more. We’re ready to provide you with professional, customized services!