Gondor Automatic Liquid Filling Machine For Sale

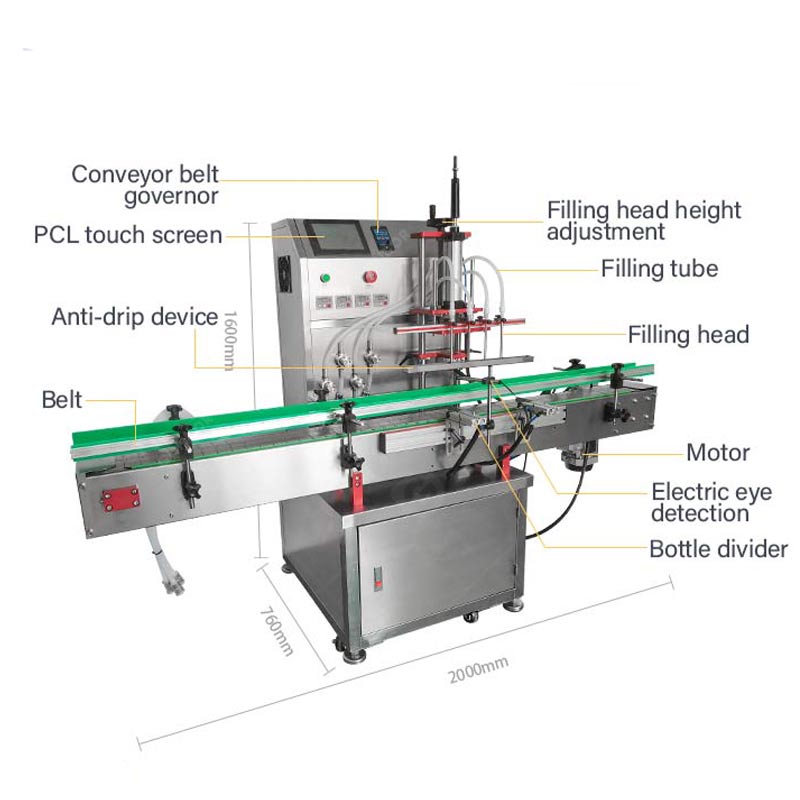

Automatic liquid bottle filling machine is a highly efficient packaging equipment. It is mainly used to accurately fill various liquids into containers of different specifications. Moreover, our equipment is usually composed of PLC control system, filling head, conveying system, etc.

Automatic Filling and Capping Specification

|

Model

|

GD-FM01

|

Name

|

Automatic filling machine

|

|

Filling Head

|

4/6/8/10/12 heads (customize)

|

Type

|

Servo control piston filling

|

|

Filling Range

|

100-5000ml (customize)

|

Accuracy

|

士1%

|

|

Speed

|

1200-2400 BPH

|

Voltage

|

AC 220V/50Hz (customize)

|

|

Air Source

|

0.5-0.8Mpa

|

Air Consumption

|

4KGSx30L/min

|

|

Power

|

2KW

|

Control Type

|

PLC touch screen control

|

|

Material

|

Frame adopts sus304,all contact part is suS316L

|

||

|

Dimension

|

3000*900*2000mm

|

Weight

|

300kg

|

Market Scope of Gondor Liquid Filling Machine

- Filling of various liquors such as liquor, beer, and wine. The filling volume can be accurately controlled to improve production efficiency.Alcohol

- It can accurately fill liquid medicine into vials and seal them to ensure the quality and safety of the medicines.Oral Liquid

- Various eye drops, nasal drops and other liquid medicines also need to be filled using liquid filling machines.Eye Drops

- Including juice, tea beverages, carbonated beverages, etc. Liquid filling machines can quickly and accurately fill beverages into various packaging containers.Beverages

- Such as soy sauce, vinegar, cooking oil, etc. These liquid condiments require precise filling equipment to ensure product quality and hygiene standards.Condiments

- The equipment can fill cosmetics such as lotions, shampoos, shower gels and other liquids into various packaging containers to meet the market demand for daily chemical products.Cosmetics

- Some liquid cleaners, such as laundry detergent and dishwashing liquid, need to be filled with efficient liquid filling machines to improve production efficiency and product quality.Cleaners

Automatic Filling Machines Application Scenarios

Outstanding Equipment Features of Gondor Automatic Liquid Filling Machine

By adopting advanced sensors and control systems, the filling volume can be accurately controlled to ensure the accuracy and stability of filling.

The structural design of the filling head is reasonable, which can ensure that the liquid will not drip and splash during the filling process.

A large number of filling tasks can be completed in a short time, which can meet the needs of large-scale production.

Accurately control and monitor the equipment, timely discover and solve problems in the production process, and ensure the stable operation of the equipment.

It is suitable for all types of liquids, including liquid products processed by pasteurizers, such as milk, juice, beverages, etc., and can effectively maintain their nutrients and taste while extending their shelf life.

It can be adjusted according to different container specifications to adapt to bottles, cans, barrels and other containers of various shapes and sizes.

Equipped with safety protection devices such as emergency stop buttons. During the operation of the equipment, these devices can protect the safety of the equipment and operators.

Gondor Automatic Liquid Bottle Filling Machine – Leader in Precision Filling

Our automatic liquid filling machine is the core equipment of Gondor’s complete liquid filling line. This high-quality, highly automated device ensures precise and error-free liquid volume in every bottle. Widely applicable for filling various liquids in the beverage, pharmaceutical, and cosmetics industries, it offers simple operation and stable, reliable performance. Choosing Gangtuo filling machines means investing not just in a single piece of equipment, but in a seamless, high-efficiency production process. This machine integrates flawlessly with our capping, labeling, and packaging equipment to build a complete high-speed production line, helping you maximize output while minimizing operational costs.