Bubble Wash Technology: For Fresher, Safer Produce

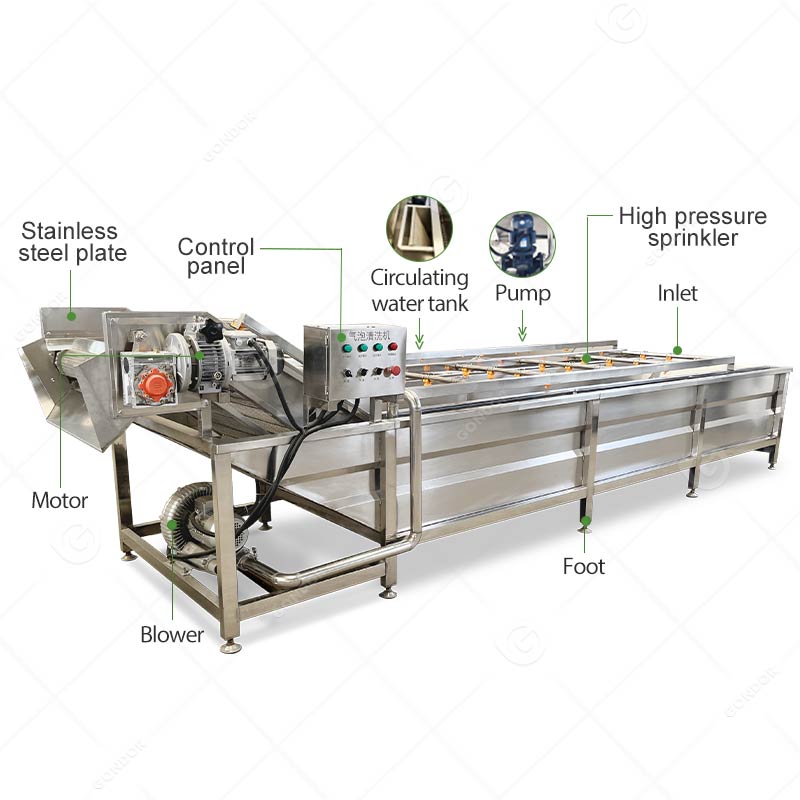

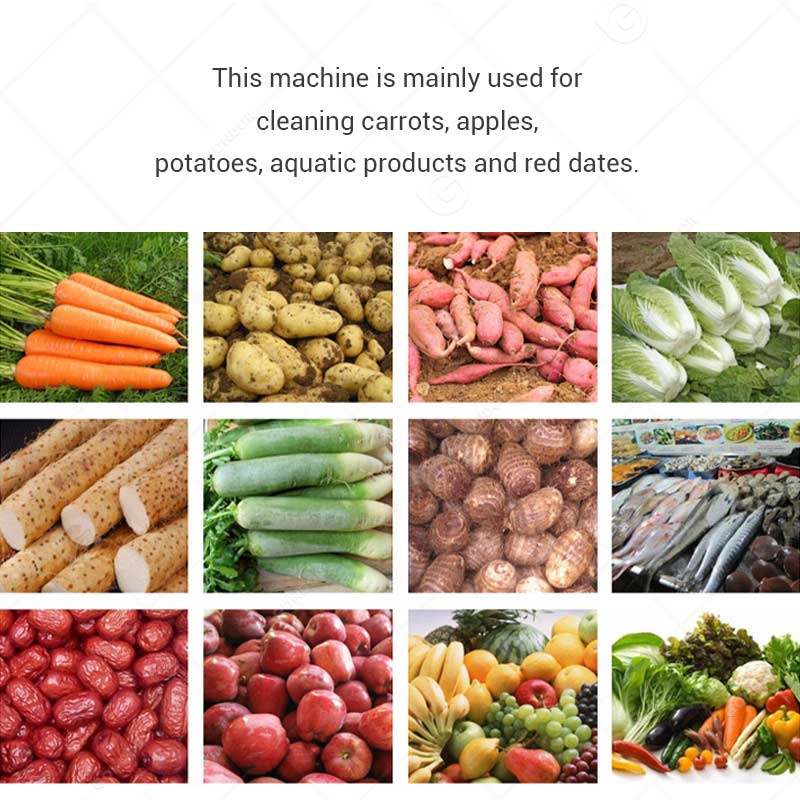

Gondor bubble vegetable washing machine is a highly efficient cleaning equipment. It uses the impact force of bubbles and the flushing force of water flow to clean all kinds of fruits and vegetables in an all-round way. During the cleaning process, the bursting of bubbles can separate the dirt from the surface of fruits and vegetables, and the water flow takes the dirt away. Besides, the equipment has the advantages of good cleaning effect, high efficiency, and no damage to fruits and vegetables. It is widely used in vegetable processing plants, fruit planting bases, supermarket fresh food areas and other places. It can effectively remove pesticide residues and impurities, allowing customers to eat more assured.

| Model | GD-3 | GD-4 | GD-5 |

| Length | 3m | 4m | 5m |

| Mesh Belt Width | 800mm | 800mm | 800mm |

| Voltage | 380V(Customizable) | 380V(Customizable) | 380V(Customizable) |

| Power | Convey 0.75KW + water pump 0.75KW + air pump 1.5KW | Convey 0.75KW + water pump 1.5KW + air pump 2.2KW | Convey 0.75KW + water pump 2.2KW + air pump 3KW |

| Material | 304 stainless steel | 304 stainless steel | 304 stainless steel |

Demand Areas for Gondor Bubble Washer Machine

Vegetable Processing Companies

Used to clean various leafy, melon and tuber vegetables, remove mud, impurities, pesticide residues, etc.

Fruit Processing Companies

Clean fruits such as apples, pears, grapes, oranges, strawberries, etc., and remove surface dust, dirt, fruit wax, etc.

Fungus Production and Processing

Clean mushrooms, fungus and other fungi to remove surface attachments and impurities.

Seafood Processing

For example, clean shellfish (such as oysters, clams, etc.), remove mud and surface algae, etc.; clean shrimps, crabs, etc., and remove surface dirt.

Kitchens of Large Hotels and Restaurants

Wash a large amount of vegetables and fruits for preparation before cooking.

Canteens

Provide catering services for a large number of teachers, students, employees, etc., and need to clean the vegetables and fruits purchased every day in batches.

Agricultural Product Distribution Center

Clean agricultural products before distribution to ensure good cleanliness and appearance when they reach customers.

Central Kitchen

Used for pre cleaning of various ingredients, providing clean raw materials for subsequent cooking, processing, and other processes.

Obvious Leading Advantages of Vegetable Wash Machine

Efficient Cleaning

Double cleaning with bubble tumbling and high-pressure spraying, good cleaning effect.

Save Manpower

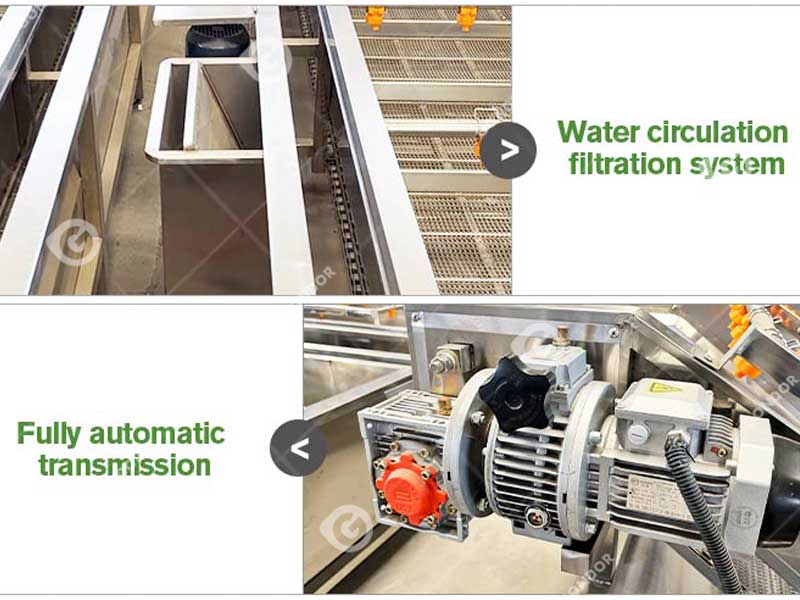

Automated operation greatly reduces the labor intensity and cost of manual cleaning.

Wide Application

Can be used to clean fruits and vegetables of all shapes, sizes and textures.

Water and Energy Saving

With a circulating water pump, it can filter sewage and reuse it, saving water.

Protect Food Ingredients

Imitating manual cleaning, almost no damage to the appearance of the material, maintaining its integrity and freshness.

Fast Cleaning Speed

The machine has a high output, cleaning 500KG of apples per hour for a 3-meter-long length, greatly improving production efficiency.

Durable and Reliable

Except for standard parts such as motors and bearings, the equipment is made of stainless steel SUS304 material, which fully meets the export food hygiene requirements.

Customized Service

The product has strong customizability and can be customized according to customers’ material and production needs.

Technical Features and Innovations

Production Line Integration Solution

To establish a complete fresh-cut produce processing line, the bubble washer can efficiently integrate with the following equipment to form an automated assembly line:

- Brush Roller Washer: Designed for deep cleaning of soil and coarse skin on root crops like potatoes, carrots, and sweet potatoes. Can be positioned before the bubble washer as a pre-wash stage.

- Sorting Conveyor: Connected after the washer, it facilitates workers in sorting and trimming washed produce to ensure final product quality.

- Vegetable Air Dryer: Installed immediately after the washer, it rapidly dries surface moisture using high-pressure cold air, effectively extending shelf life and preparing produce for subsequent fresh-packaging, cutting, or quick-freezing processes.

- Vacuum Cooler: For ingredients like leafy greens requiring rapid pre-cooling, this equipment can be integrated to achieve refrigeration temperatures in minimal time, locking in freshness and crispness.

Gondor Bubble Vegetable Washing Machine – Embrace Cleanliness and Efficiency

Gondor bubble vegetable washing machine uses advanced bubble impact technology to deeply clean vegetables, fruits and various ingredients. Whether it is mud, impurities or pesticide residues, they can be easily removed. High efficiency and energy saving, easy operation, saving manpower and time costs. Sturdy and durable, easy to maintain, providing long-term and stable guarantee for your production. Choose our bubble washer machine to improve the quality of ingredients, ensure food safety, and make your food processing easier and more efficient. Order it now to add a strong boost to your business!