Gondor Chalk Making Machine

Chalk making machine is becoming an ideal choice for more and more stationery factories and entrepreneurs in the field of educational supplies and artistic creation materials. Whether you want to build your own chalk brand or expand the existing production line, this equipment will bring you reliable productivity and excellent quality.

The fully automatic chalk manufacturing machine mixes gypsum (or calcium carbonate) powder, pigment, and water in a specific ratio, and then automatically completes the molding, solidification, demolding, drying, and collection processes. It is a complete set of equipment that can be directly connected to a packaging line, with a capacity of 12,000–24,000 chalks per hour. It can produce dust-free, colored, and irregularly shaped chalks, replacing traditional manual molding and sun-drying processes, achieving one-stop continuous production from “material preparation → molding → hardening → finished product”.

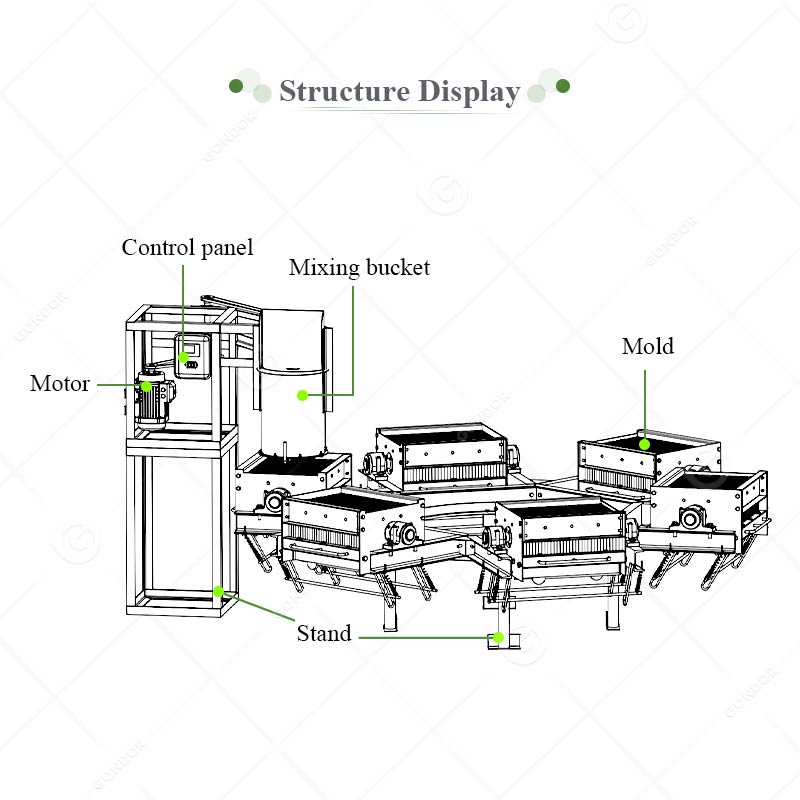

This machine has the functions of automatic water supply, electric stirring, automatic mold filling and rapid demoulding, etc. The structure adopts thickened steel frame and reinforced frame, which runs smoothly and can meet the needs of long-term and high-load production.

Chalk Making Machine Specification

| Model | Capacity(pcs/h) | Mould quantity | Chalk size | Power | Weight | Packing size |

| GD400-1 | 2000 | 1 set | 10*8*75mm | 220v | 29kg | 500*320*350mm |

| GD800-1 | 4000 | 1 set | 10*8*75mm | 220v | 56kg | 640*470*360mm |

| GD800-2 | 8000 | 2 sets | 10*8*75mm | 220v | 220kg | 112*108*760mm |

| GD800-4 | 8000 | 4 sets | 10*8*75mm | 220v | 320kg | 173*112*760mm |

| GD800-6 | 24000 | 6 sets | 10*8*75mm | 220v | 480kg | 173*112*760mm |

| GD800-6 | 32000 | 8 sets | 10*8*75mm | 220v | 650kg | 148*148*560mm

112*108*760mm |

| GD-100 | 80000-90000(pcs/8h) | / | / | 380V 5.5kw | 1200kg | 220*80*145mm |

Applicable Industries of Chalk Mouling Machine

Chalk making machine is suitable for the following industries and projects:

Used to manufacture high-quality white or colored chalk suitable for various blackboards and teaching scenarios.

Capable of producing colored chalk and scented chalk to meet artistic creation needs.

Low-cost investment, easy operation, no professional training required.

Capable of supplying standard-sized or custom-shaped chalk in bulk quantities.

Efficiency Advantages of Chalk Making Machines

Compared to traditional manual chalk production methods, this automatic chalk making machine offers significant advantages in efficiency and quality:

Production Process Overview

Why Choose Our Automatic Chalk Making Machine?

- Stable Production: Consistent performance with continuous, trouble-free operation.

- Multi-Shape Support: Capable of producing circular, square, hexagonal, and custom shapes.

- Compact Design: Requires only 12 square meters of space for installation and operation.

- Standard Power Supply: Operates on 220V single-phase electricity without requiring special modifications.

Related Machines

If you plan to expand your production line, we also offer a range of auxiliary and supporting equipment, such as:

- Chalk Dryer Machine

- Chalk Packaging Machine

- Gypsum Powder Mixer

Choose Gondor‘s chalk making machine to make your chalk production line more efficient and intelligent, helping you build your own global stationery brand!