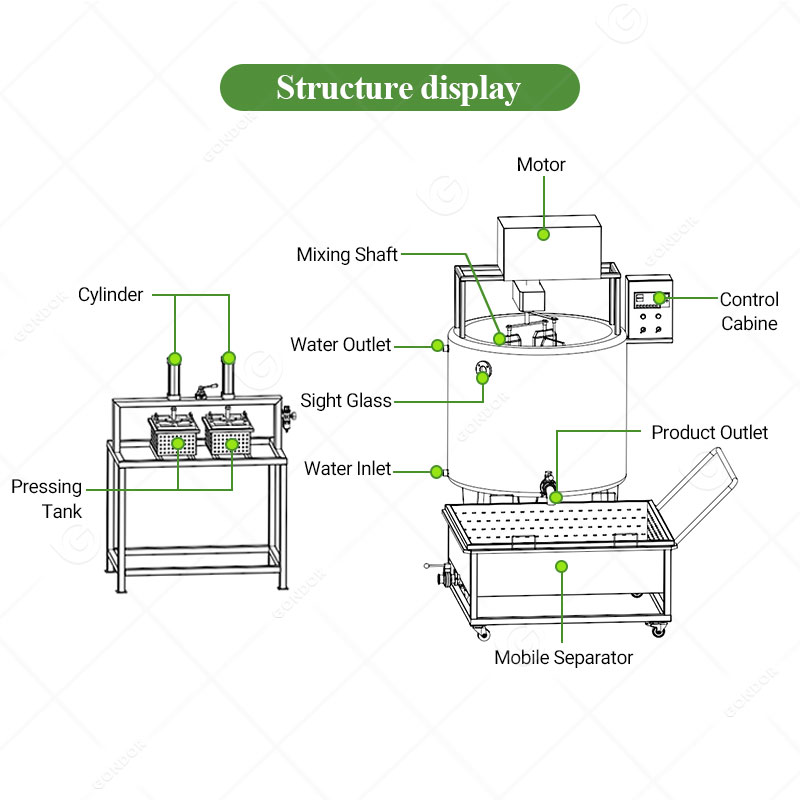

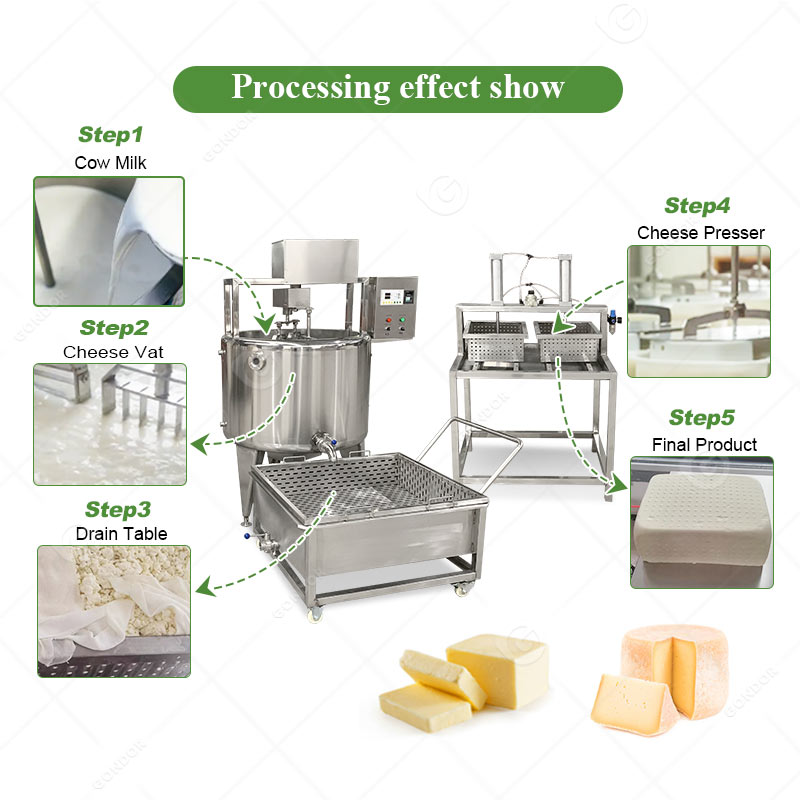

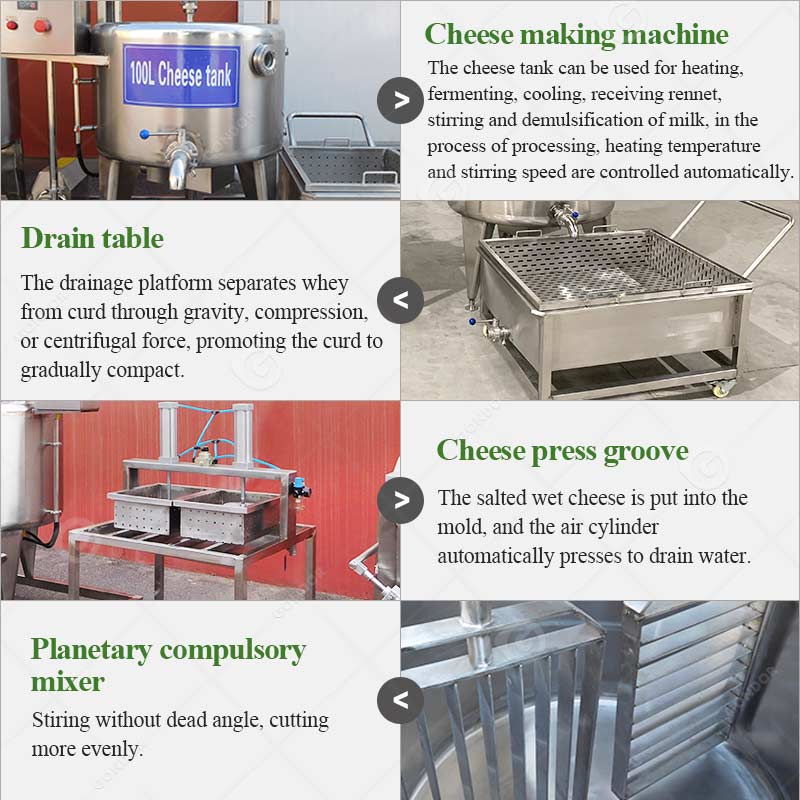

Gondor cheese making machine is a multifunctional equipment integrating automatic temperature control, variable frequency stirring and intelligent fermentation, which is suitable for domestic and industrial production. The whole machine is made of stainless steel, with solid structure, modular design to support one-button disassembly, clean and convenient without dead ends. When in use, the system can automatically complete the steps of heating, fermenting, cooling, stirring, etc. only by pouring milk into the cheese tank, and the operation is simple and the process is controllable. After the whey is separated, it is pressed and shaped, and the planetary stirrer is matched to ensure uniform stirring and stable quality of the finished product.

Applicable Industries of Cheese Making Machine

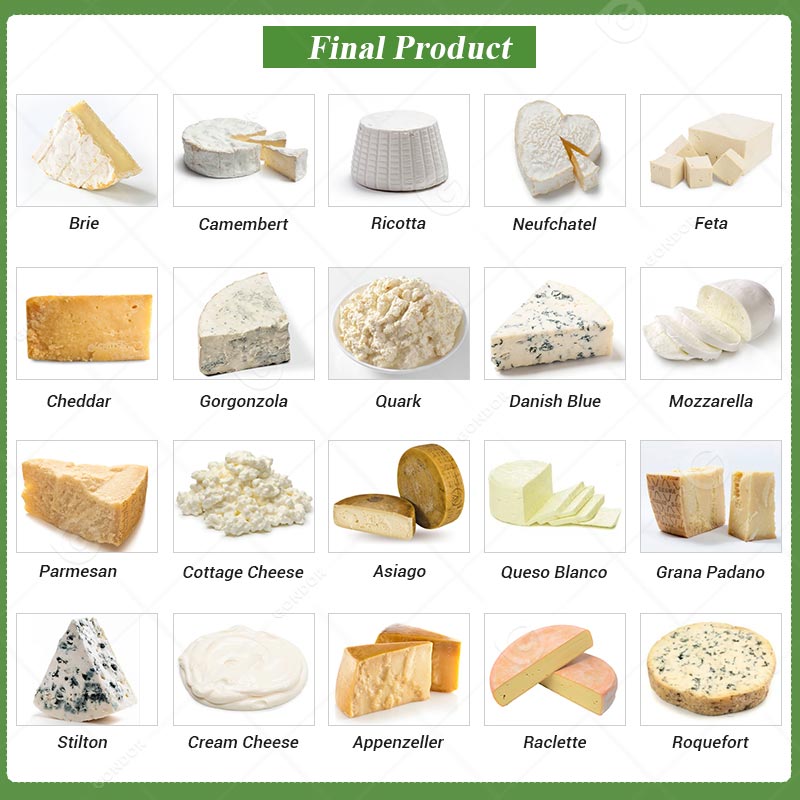

It is used to produce various types of cheese on an industrial scale to meet the market demand in large quantities.

It is suitable for restaurants, cheese bars and cafeterias to make fresh cheese on the spot.

It is convenient for home users to easily try various cheese recipes and improve their quality of life.

Converting raw milk into cheese products with higher added value.

Key Functional Advantages of Cheese Making Machine

Related Equipment

- Milk Production Machine: The whole line integrates milk receiving, sterilization, homogenization, fermentation, filling and other processes to realize efficient and automatic dairy processing.

- Milk Pasteurizer Machine: By controlling the temperature and time, it can effectively sterilize and retain nutrition, which is suitable for the treatment of liquid dairy products such as milk and yogurt.

- Milk Homogenizer Machine: Refine fat globules, improve the taste and stability of dairy products, and prevent stratification. It is often used in milk and juice products.