Gondor Cocoa Bean Peeling Winnowing Machine

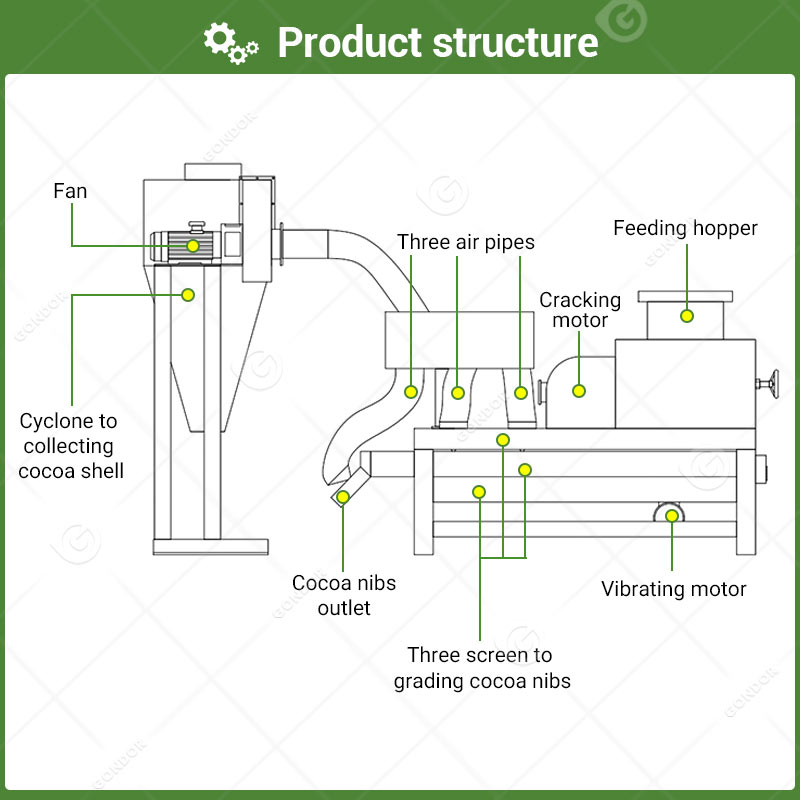

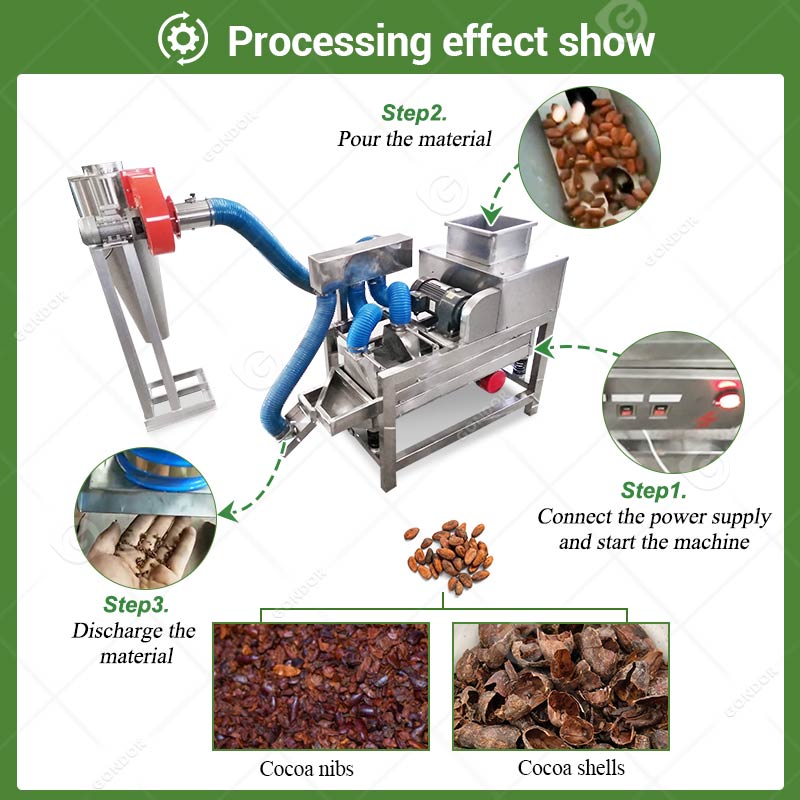

The cocoa bean winnowing machine is the key equipment in cocoa processing, which is mainly used to efficiently separate the crushed kernels and shells of cocoa beans. It integrates precision crushing, efficient air separation, intelligent control, and energy saving, thus improving processing efficiency and product quality.

The equipment adopts advanced air separation technology and realizes the fine separation of cocoa kernels and shells by adjusting air volume and crushing strength. In addition, the equipment is easy to operate, easy to maintain and stable in operation, so it is an ideal choice for modern cocoa processing enterprises.

Commercial Cocoa Bean Peeling Winnowing Machine Specification

| Gas heating | ||||||

|

Model |

Capacity | Weight | size (cm) | Voltage | Power | Fan power |

|

GD-CBPM1 |

50-100kg/h | 120kg | 100*100*130 | 380V | 0.4KW | 0.37KW |

| GD-CBPM2 | 100kg/h | 150kg | 140*60*130 | 380V | 0.75KW |

1.1KW |

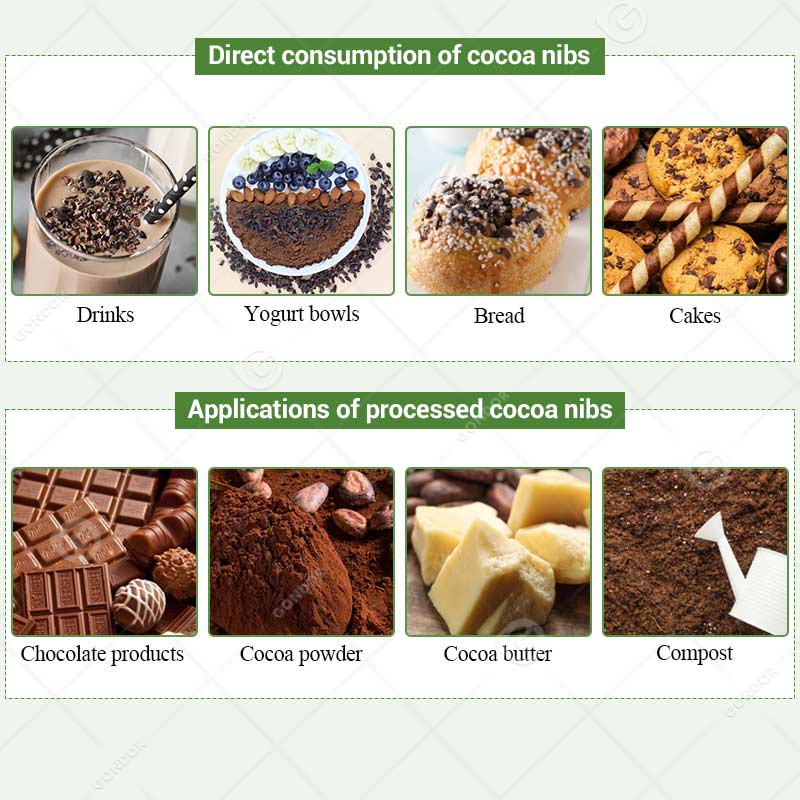

Applicable Industries of the Cocoa Bean Peeling Machine

The cocoa bean peeling machine is widely used in:

Cocoa Bean Cracker and Winnower’s Quality Advantages

Equipped with high-precision crushing components, the particle uniformity is high, the cocoa kernel is not damaged, and its natural flavor and nutritional value are effectively retained.

Separation of kernel and shell by aerodynamic difference. The light cocoa shells were separated by the wind, and the heavy cocoa kernels settled smoothly in the collection area, with a separation rate as high as 98%.

The intuitive operation panel can adjust the air volume, crushing spacing, and conveying speed, and flexibly adapt to the processing needs of cocoa beans with different varieties and different dry humidity.

Adopt high-efficiency motor and energy-saving structure design while ensuring strong processing capacity, significantly reduce energy consumption and save long-term operating costs for enterprises.

Modular Structure Design

Our machine adopts the modular design concept. When it is necessary, the crushing unit, air separation system and collection tray can be quickly disassembled and reassembled. Therefore, it can greatly simplify maintenance, shorten cleaning time, as well as facilitates future upgrades or integration into automated lines.

Cocoa Variety Compatibility

It can be used to handle cocoa bean in various sizes and different origins, from West African Forastero to South American Criollo and Trinitario. What’s more, With customizable settings, the machines maintain consistent peeling and separation performance across diverse bean characteristics.

Low Noise & Vibration Control

When designing the cocoa bean cracker and winnower, we adopt a vibration-dampening base and optimized airflow design, which can effectively reduce the operational noise and machine movement. Moreover, it can ensures a quieter working environment and reduces wear on mechanical parts, which can prolong the service life.

Continuous Feed & Discharge System

With a continuous feeding hopper and automatic discharge structure, Gondor cocoa bean winnowing machines support uninterrupted batch processing. What’s more, it can greatly improve your production efficiency. Meanwhile, it allows seamless integration with upstream roasting and downstream grinding for efficient cocoa processing.

Precise Crushing and Intelligent Air Separation

To create a more efficient all-in-one cocoa processing solution, you can also use the following equipment together:

- Commercial Peanut Roaster: Bake cocoa beans evenly to enhance aroma and optimize shelling effect.

- Peanut Butter Making Machine: High-efficiency fine grinding of cocoa crumbs to make fine cocoa pulp.

- Industrial Powder Grinder Machine: The dry material is made into cocoa powder with adjustable particle size and uniform powder output.