Gondor Dry Ice Pellet Making Machine

Dry ice pelletizer making machine is a kind of equipment specially used for making dry ice pellets. It can convert liquid carbon dioxide (CO2) into dry ice pellets to meet the needs of low-temperature freezing, preservation, special effects and cleaning in different industries and application fields. The machine has efficient and stable performance, provides convenient and efficient dry ice solutions for various industries, and is a powerful assistant for modern production and life.

Dry Ice Granulator Specifiation

| Model | Production capability | Dry ice specification | The density of dry ice | Liquid and solid co2 conversion ratio | The total power | Equipment weight | Overall dimensions |

| GD-DIPM50 | 40-50 kg/h | Φ3mm,Φ16mm | 1550kg/m³ | ≥42% | 3kw | 175kg | 100×48×102cm |

| GD-DIPM100 | 100kg/h | Φ3mm,Φ10mm,

Φ16mm, |

1550kg/m³ | ≥42% | 4kw | 380kg | 145×60×142cm |

| GD-DIPM120 | 120-180kg/h | 125×105×70/80mm | 1450-1550kg/m³ | ≥42% | 4.5kw | 360KG | 128×56×134cm |

| GD-DIPM150 | 150kg/h | Φ3mm,Φ16mm, Φ19mm |

1550kg/m³ | ≥42% | 7.5kw | 3600kg | 165×65×168cm |

| GD-DIPM300 | 300-350kg/h | Φ3mm,Φ16mm, Φ19mm |

1550kg/m³ | ≥42% | 8kw | 1100kg | 165×115×168cm |

| GD-DIPM500 | 500-550kg/h | Φ3mm,Φ16mm, Φ19mm |

1550kg/m³ | ≥42% | 18.5kw | 1650kg | 178×135×180cm |

Related Industries Using Gondor Dry Ice Making Machine

During the long-distance transportation and storage of food, dry ice pellets can provide a stable and lasting low temperature environment to ensure the freshness and taste of food and extend the shelf life of food.

Dry ice can be used to freeze and dry medicines and preserve biological samples. Dry ice is also a necessity during the transportation of medical products such as vaccines and blood products, which can ensure the quality and safety of these products during transportation.

It has unique advantages in cleaning the oil stains on the surfaces of integrated circuit boards, electronic components and petrochemical equipment. It avoids the environmental pollution and equipment corrosion problems that may be caused by traditional cleaning methods.

As an efficient cooling medium, dry ice pellets are used to cool electrical equipment, such as transformers, cables, etc. In addition, it can also be used to remove dust and dirt on the surface of electrical equipment to improve the insulation performance and safety of the equipment.

In carbon capture, utilization and storage (CCUS) technology, the dry ice pelletizer can convert the captured carbon dioxide into dry ice pellets, which are easy to store and transport, and reduce greenhouse gas emissions.

Advantages of the Use of Gondor Dry Ice Pellet Making Machine

- It can quickly convert carbon dioxide gas into dry ice pellets, greatly improving production efficiency. It can meet the production needs of different scales and save time and cost for enterprises.Efficient Production

- The use of carbon dioxide gas as raw material reduces pollution to the environment. At the same time, dry ice will directly sublimate into carbon dioxide gas after use, and will not produce any waste, which meets environmental protection requirements.Energy Saving and Environmental Protection

- Suitable for multiple fields, such as food preservation, industrial cleaning, stage effects, etc. Provided convenient and efficient dry ice solutions for different industries, with high practical value.Wide Application

- Most dry ice pelletizers have adjustable parameters, allowing users to make dry ice pellets of different sizes and shapes as needed.Adjustable Parameters

- Usually those machines have multiple levels of safety features to ensure the safety and reliability of the equipment to protect operators from the dangers of CO2 gas and machinerySafe and Reliable

- The hydraulic pump station and pellet forming module are both built-in, which reduces the footprint of the equipment on the one hand, and avoids the influence of dust on the other hand.Built-In Components

Gondor Dry Ice Pelletizer Machine Usage Process

First, you need to prepare the raw material for dry ice, usually liquid carbon dioxide (CO2), which is usually stored in a carbon dioxide gas tank.

Use an appropriate high-pressure gas pipeline or hose to connect the CO2 gas tank to the dry ice granulator. Make sure the connection is secure to prevent gas leakage.

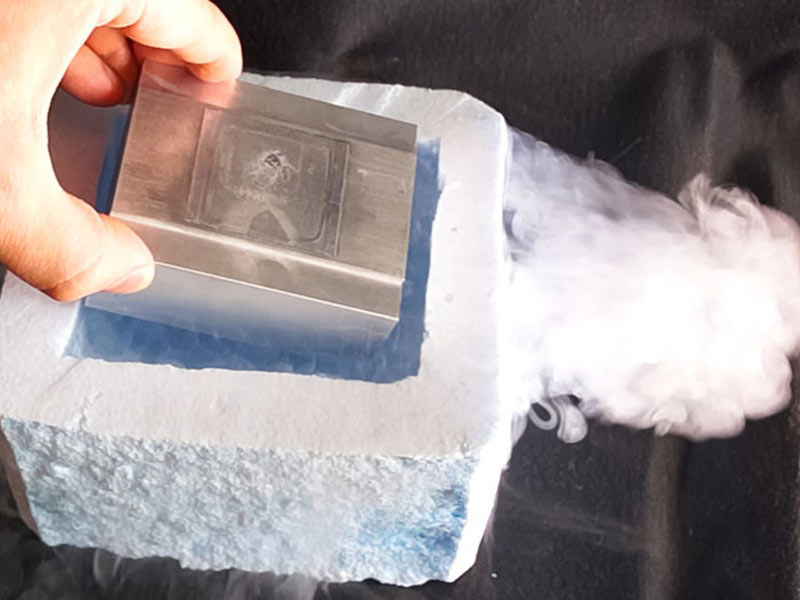

Start the dry ice machine and set the required parameters to start making dry ice pellets. Usually, the machine automatically controls the refrigeration and granulation process. Dry ice comes out of the ice outlet.

Once the production is completed, close the valve of the CO2 gas tank and stop the operation of the dry ice machine. Wait for a while to ensure that any CO2 gas remaining in the system is released or discharged.

Dry Ice Pellet Artifact – Gondor Dry Ice Pelletizer Making Machine Is Coming

Dear customers, Gondor dry ice making machine is your ideal choice! Widely used in food, medical, industrial and other fields, providing you with efficient low temperature solutions and cleaning methods. Precisely manufacture dry ice pellets with reliable quality. Choosing our means choosing efficiency and professionalism. Come and order, let Gondor dry ice pellet making machine add powerful support to your business!

Gondor Dry Ice Pelletizer Machine Features

High Efficiency and Energy Saving:

Modern dry ice granulators mostly adopt PLC automatic control systems, enabling continuous production with low energy consumption and high efficiency.

Adjustable Pellet Size:

By changing the molds, dry ice pellets of different diameters (e.g., 3mm, 6mm, 16mm) can be produced to meet various application needs.

Compact Structure and Easy Operation:

Most machines adopt a cabinet-style or stainless steel enclosed structure, occupying little space, with low noise and easy maintenance.

Safe and Reliable:

The equipment is usually equipped with safety systems such as low-temperature protection, pressure monitoring, and automatic alarms to ensure stable operation.

Environmentally Friendly and Pollution-Free:

Dry ice pellets directly sublimate into CO₂ gas during use, leaving no residue and causing no pollution, making them suitable for high-requirement industries such as food and pharmaceuticals.