Electric chinchin cutter is a kind of equipment specially designed for cutting and making traditional snacks in West Africa. Chin Chin is a small snack similar to fried pastry, usually made of dough mixed with flour, sugar, butter and milk and fried. It is very popular in West African countries such as Nigeria and Ghana, and often used as daily snacks or festival food. In addition, using our equipment can greatly improve the efficiency of making Chin Chin, especially for restaurants, pastry shops or food processing plants that need large-scale production.

Electric Chin Chin Cutter Machine Specification

| Model | Power | Voltage | Capacity | Size | weight |

| GD-CCCM-300 | 1.5kw | 380v/50HZ | 300-1000kg/h | 2200*650*1460 mm | 230kg |

| GD-CCCM-350 | 1.5kw | 220v | 300-1000kg/h | 1700*600*1050mm | 200kg |

Main Markets for Gondor Electric Chin Chin Cutter

- It can improve production efficiency and ensure product consistency in line with market demand and standards. At the same time, it can reduce the time and cost required for manual cutting.Food Processing Plants

- Small food companies purchase this equipment to improve the efficiency of manual production and increase production to meet the needs of the local market.Small-Scale Food Manufacturers

- This equipment is a good commodity choice. Whether it is a small device for home use or a commercial device for small merchants, there is a certain market demand.E-Commerce Platforms

- Chin Chin is a very popular snack in restaurants that serve West African dishes or international snacks. The use of machines can quickly make Chin Chin, shorten preparation time, and improve customer satisfaction.Restaurants and Fast Food Restaurants

- In West African countries and West African community gathering areas, street vendors and local market stall owners usually sell Chin Chin. Using Chin Chin Cutter allows them to make more products in a short time.Local Markets and Street Stalls

- Chin Chin and other specialty snacks are exported to North America, Europe and other regions with West African communities or restaurants, which can provide new market opportunities for manufacturers of food processing equipment.Export Market

Considerable Benefits of Gondor Chinchin Cutter

Compared with manual cutting, Chin Chin Cutter can efficiently cut a large amount of dough in a short time, thereby greatly improving production speed.

Chinchin cutter can ensure product quality consistency and stability, improve product appearance and taste consistency, and meet the market demand for standardized products.

Using Chin Chin Cutter can reduce dependence on manual labor and reduce labor costs. It enables a small number of workers to handle more production tasks, greatly improving the output per unit of work.

The operation interface and design are very simple, and employees can get started after a short training, reducing training costs and operating thresholds. And the equipment maintenance is relatively simple.

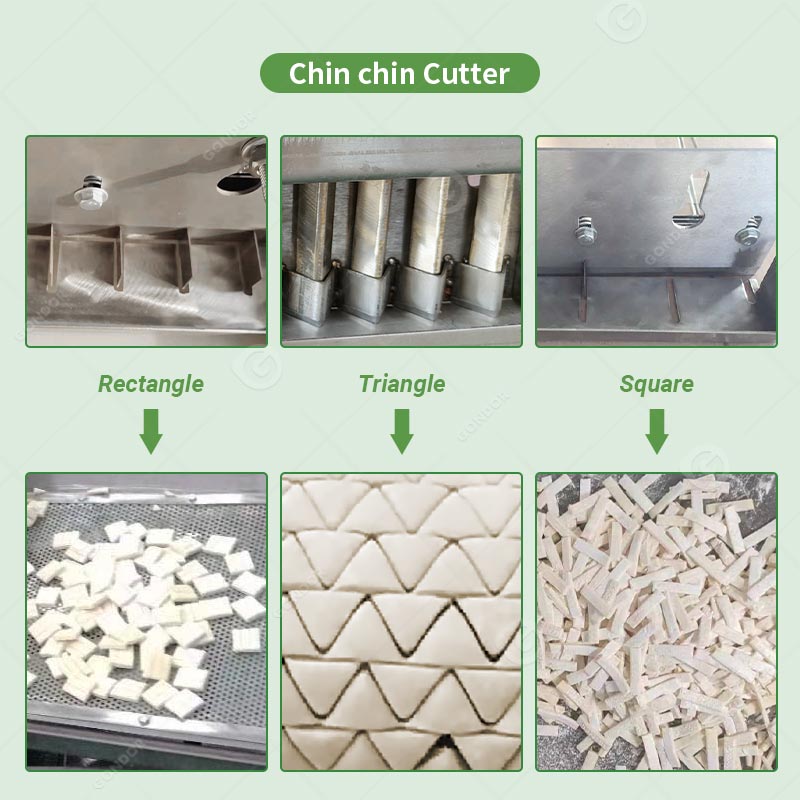

Many Chin Chin Cutter devices support adjusting blades and cutting modes, and can produce Chin Chin of different shapes and sizes to meet the market demand for diversified products.

Whether it is a small business or a large food processing plant, you can optimize the production scale by choosing the right specifications of Chin Chin Cutter, thereby improving production flexibility.

By improving production efficiency and reducing labor and operating costs, companies using Chin Chin Cutter can obtain higher profit margins and provide consumers with more competitively priced products.

Although the initial purchase cost may be high, the efficient production, low maintenance cost and labor cost savings of Chin Chin Cutter can recover the investment in a short time and bring long-term economic benefits.

Gondor Electric Chinchin Cutter-Efficient Tool

If you are looking for a Chin Chin cutting device that can improve efficiency and ensure product consistency, Gondor electric chinchin cutter is definitely your best choice! It can quickly and accurately cut the dough into uniform shapes, which can reduce manual operation time and costs. Whether it is a small family workshop or a large-scale production enterprise, our equipment can help you easily increase production, meet market demand, and significantly improve production efficiency. Order now and experience efficient and reliable chinchin making equipment!