The whole machine of the fish head cutting cutter machine is made of food-grade stainless steel, which offers the advantages of rust resistance and corrosion resistance. Additionally, the cutter is made of special manganese steel (stainless steel 402), which is not only suitable for cutting hairtail and knife fish but also ensures a long service life. The equipment features a compact design, a beautiful appearance, easy operation, low power consumption, and an excellent bone sawing effect. Moreover, the length of the hairtail segments can be customized according to user needs, allowing it to meet diversified processing requirements. Its automatic cutting function is highly efficient, with neat cuts and no debris, while different parts are separated through different discharge ports for easier processing. The equipment also supports variable frequency speed regulation, is simple to operate, and only requires two people. As a result, it is widely used in food processing plants, aquatic product processing plants, and other similar units.

| Model | GD-1 | GD-2 |

| Capacity | 1000kg/h | 200kg/h |

| Size | 1360*1170*1060mm | 1100*500*850mm |

| Weight | 165kg | 700kg |

Fish Head Cutting Machine Mainly Serves Industry Fields

Fish cutting machines are widely used in many industries. Due to their efficient and precise cutting functions, they can meet the processing needs of different types of fish and other strip materials, significantly improve production efficiency and reduce labor costs. The following are the industry areas it mainly serves:

Excellent Efficiency Advantage of Gondor Fish Head Cutter

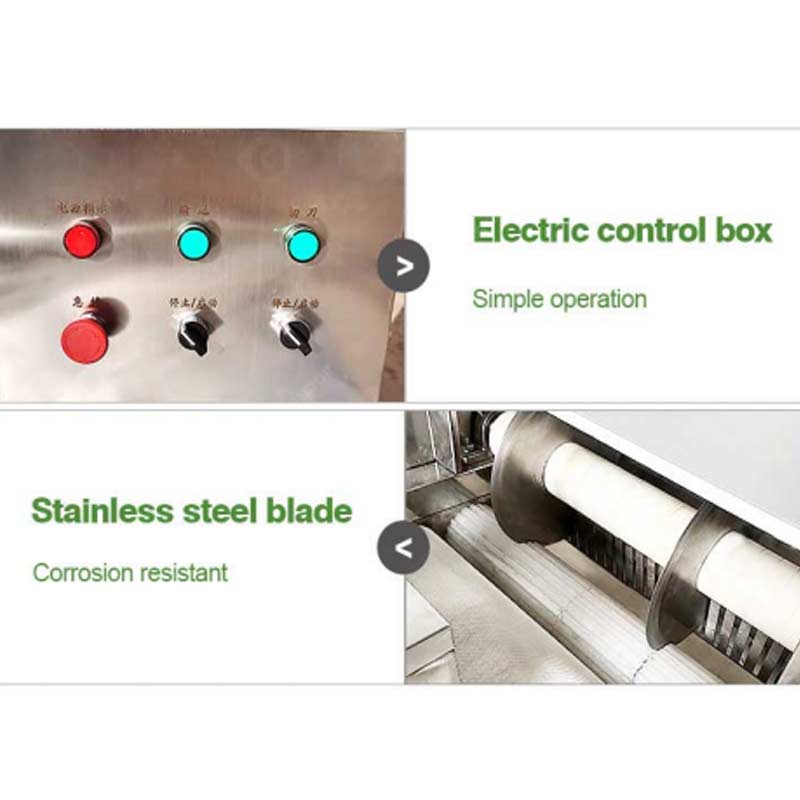

This equipment features a fully automatic cutting function, significantly reducing manual labor and enhancing production efficiency.

The cut fish segments are neat and uniform, without debris residue, ensuring that the product quality meets high standards.

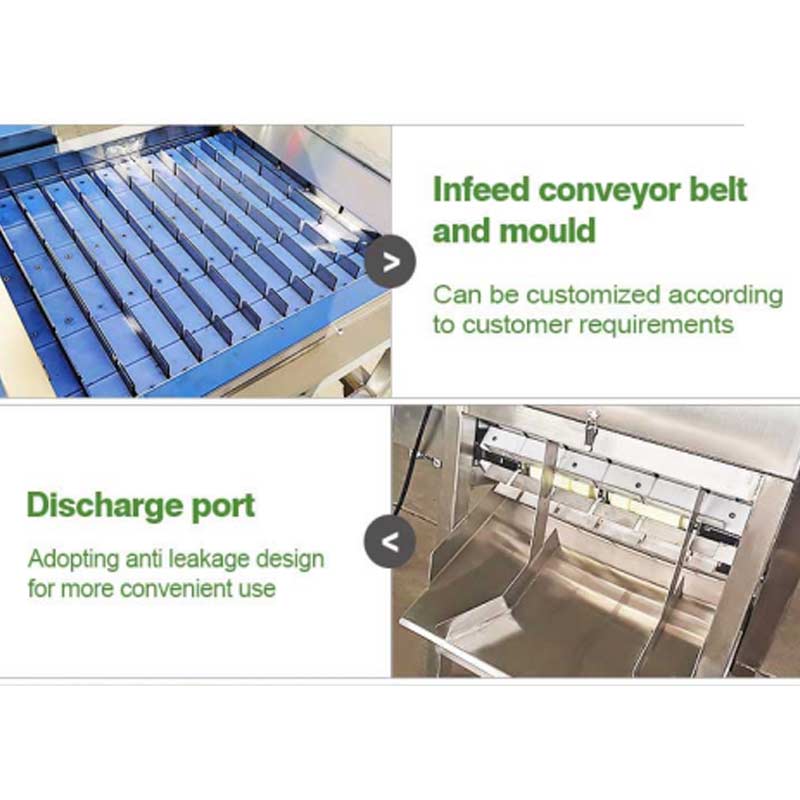

Different parts (fish head, fish body, fish tail) are separated through different discharge ports, which is convenient for subsequent processing and saves time.

Not only suitable for hairtail and knife fish, but also can cut kelp, dried meat and other ingredients to improve equipment utilization.

With support for variable frequency speed regulation, the cutting speed can be adjusted flexibly to match different production requirements.

The equipment is simple and easy to operate, and only two people are needed to complete the operation efficiently, reducing labor costs.

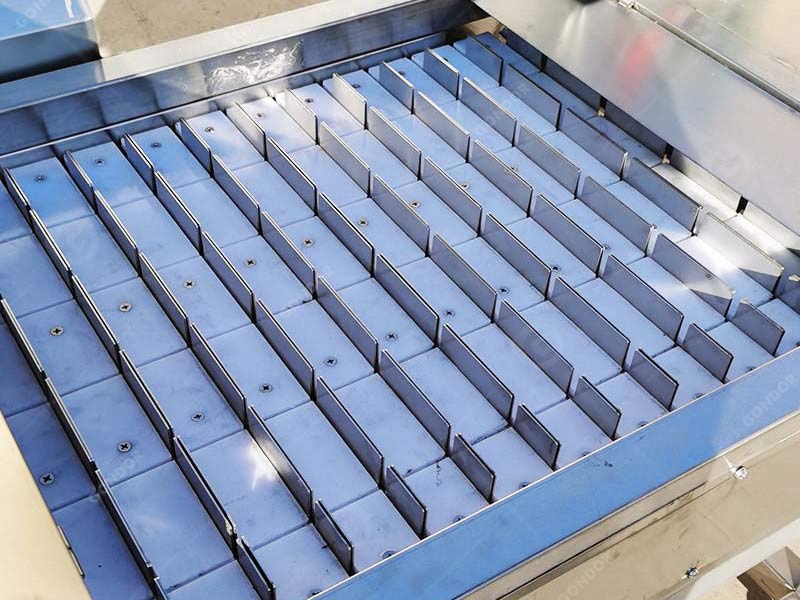

Fish segment lengths can be customized based on user preferences, catering to diverse processing needs and minimizing the need for frequent adjustments.

This equipment is widely applicable across various processing industries, enabling companies to efficiently handle large orders and boost production capacity.

Gondor Hairtail Slicing Machine – Ideal for Efficient and Intelligent Processing

If you are looking for equipment that can both improve production efficiency and reduce labor costs, the fish head cutting cutter machine is undoubtedly your best choice. With its fully automatic cutting function, it cuts neatly without leaving debris, while the fish head, body, and tail are discharged separately, making post-processing much easier. Furthermore, the equipment supports variable frequency speed regulation, allowing you to flexibly adjust the cutting speed according to different requirements. Whether you are processing hairtail, knife fish, or other strip-shaped ingredients, this machine can handle them perfectly, meeting a wide range of processing needs. In addition, the operation is straightforward, requiring only two operators to manage efficiently, which significantly boosts production capacity. Therefore, the hairtail slicing machine is ideal for various processing plants and will serve as a valuable assistant in enhancing your production efficiency.