Fish Deboning Machine: High-Efficiency Separation

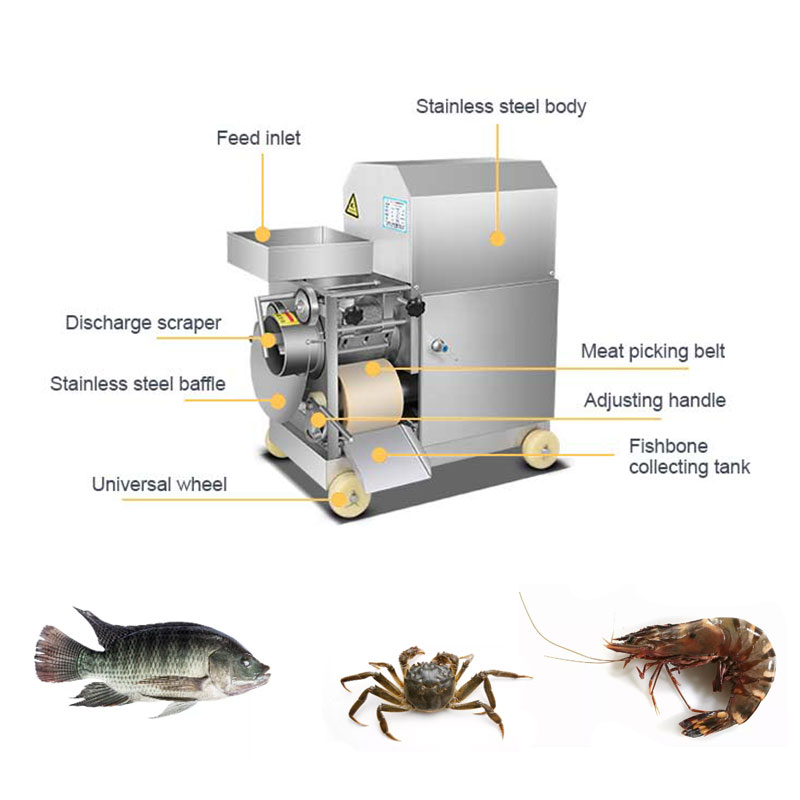

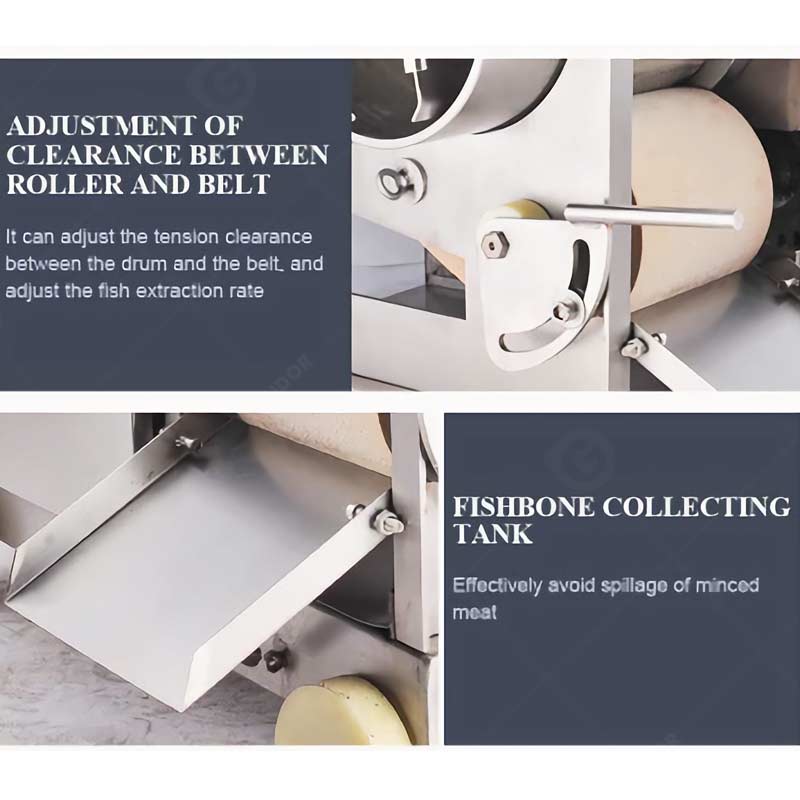

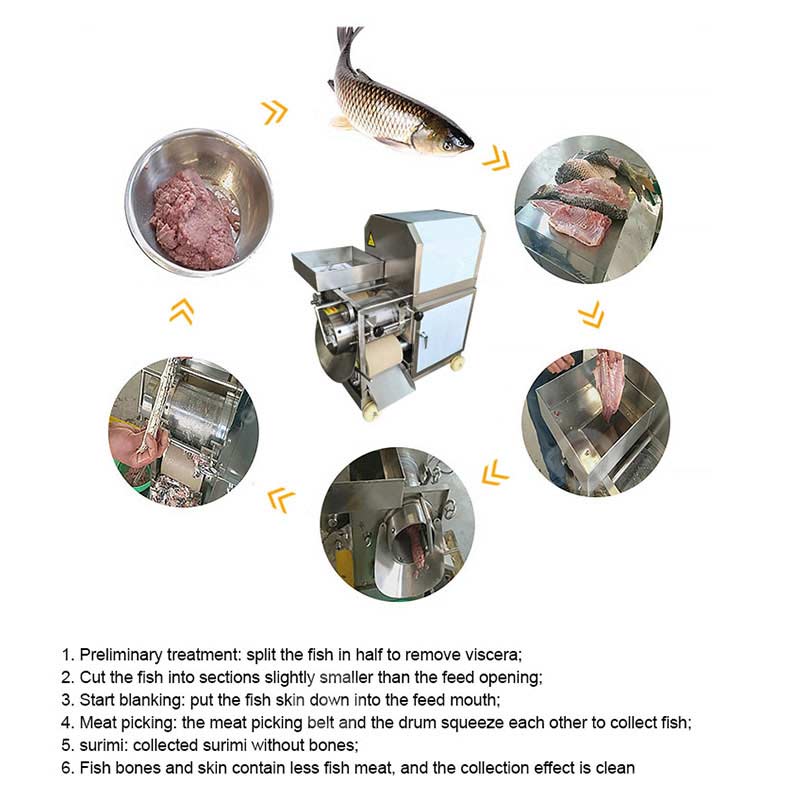

Fish meat deboning separator process machine is an efficient and practical device, driven by a high-power motor and constructed from thickened stainless steel, making it sturdy and durable. Additionally, it supports direct water washing for convenient cleaning. This machine uses an extrusion principle to effectively separate fish meat from bones and is widely used for processing fish meat, shrimp shells, and fish bones, thus ensuring a delicate meat texture. Furthermore, the equipment features an adjustable gap between the drum and belt, allowing for flexible control over the fish meat extraction rate. The fish bone collection tank, made of food-grade stainless steel, effectively prevents minced meat from overflowing, while the scraper device inside the drum smoothly removes the fish meat, ensuring a continuous extraction process. With its simple structure and easy operation, this fish deboning process is ideal for improving the efficiency of fish meat collection.

|

Model

|

GD-150

|

|

Voltage

|

220/380V (customized)

|

|

Motor power

|

1.5kw

|

|

Diameter

|

2.7mm

|

|

Material of machine body

|

SS304 (Except standard parts)

|

|

Production

|

180kg/h

|

|

Dimension

|

800*650*845mm

|

Demand Areas for Gondor Machinery’s Fish Deboning Machine

Used for large-scale fish meat separation and processing, improving processing efficiency and reducing labor costs.

Produce fish balls, fish cakes, fish floss and other fish products to ensure that the raw materials of the products are pure and boneless, and improve product quality.

Especially Japanese restaurants, hot pot restaurants and other catering places that require a large amount of fish meat raw materials, can quickly separate fish meat and improve meal preparation efficiency.

Reprocess some discarded fish and defective fish to improve resource utilization.

Used to separate fish bones and make fish meat pet food to ensure safety and meet the purity requirements of pet food.

Meet the needs of some retailers for high-quality fish meat and provide consumers with convenient boneless fish meat.

Efficiency Advantages of Gondor Fish Meat Separator

By adopting the squeezing principle, it is possible to quickly separate fish meat from bones, greatly improving processing speed.

The equipment uses thickened stainless steel material and supports direct water washing, reducing cleaning time and maintenance costs.

By adjusting the gap between the drum and the belt, ensure a high fish meat collection rate, fine meat and boneless meat, and meet high quality requirements.

Automated operation is simple and easy to use, reducing the need for manual separation of fish bones and improving production efficiency.

Equipped with a fish bone collection tank to prevent minced meat from overflowing, improve fish meat utilization, and reduce raw material waste.

One machine is multi-purpose, suitable for processing a variety of aquatic products such as fish and shrimp, expanding the application scenarios of the machine.

Efficient Fish Meat Extraction — Choose Gondor Quality

The gondor fish meat extractor is driven by high-efficiency extrusion separation technology and high-power motor, which can quickly separate fish meat from fish bones and shrimp shells. The equipment body is made of thickened food-grade stainless steel, which supports direct washing, is firm and easy to clean, and fully meets the food hygiene standards. Adjustable roller gap and automatic scraper design make the operation simple, the meat yield is high, and the labor and raw material costs are obviously saved. Whether it is an aquatic product processing plant, a catering central kitchen or a pet food production line, the processing efficiency and product quality can be greatly improved.

If you need to build a systematic aquatic product processing production line, you can match this machine with the fish head cutting machine to realize continuous processing from cutting to taking meat. It can also cooperate with automatic shrimp peeling machine to complete the integrated process of shrimp shelling and meat taking. Welcome to send an email or fill in an inquiry, get detailed product information and customized solutions, and empower and increase efficiency for your production!