Gondor Gummy Candy Production Line Introduction

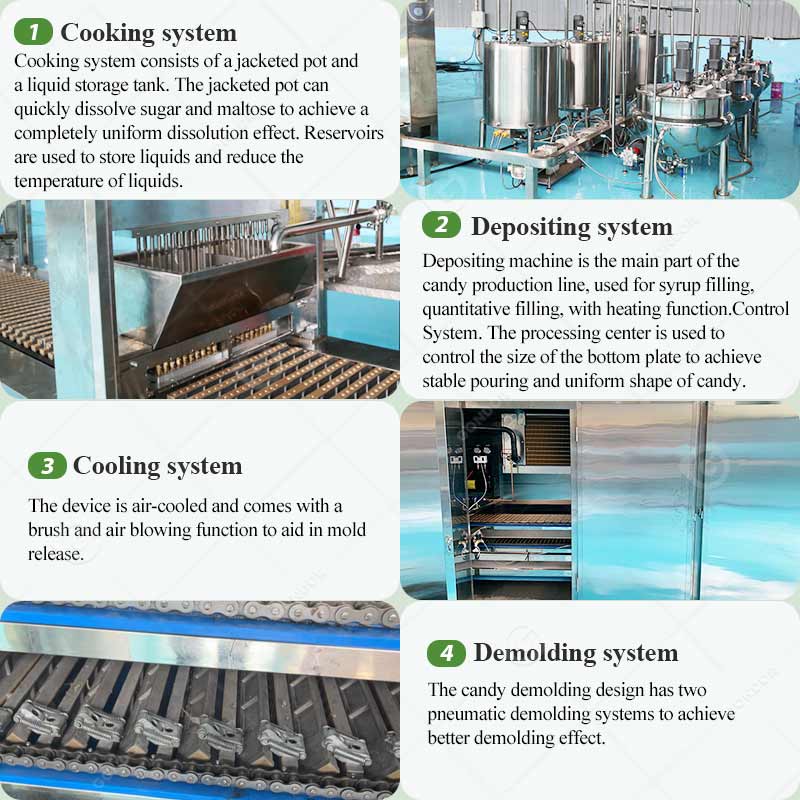

In today’s diversified confectionery market, having an efficient and stable gummy candy production line is key to brand success. Our system automates the entire process from raw material processing and precise formulation to finished product packaging: gelatin or pectin base materials are efficiently dissolved through a gelling machine and a sugar-melting pot, while flavorings, colorings, and vitamins are precisely added using an advanced mixing pot.

Whether you’re targeting the traditional retail market for casual snacks or specializing in probiotics and collagen-based gummy manufacturing lines, we are committed to providing you with superior support from diversified packaging to flexible production, helping your products stand out in the food and health supplement industry.

Gondor Gummy Candy Production Line Models

Our gummy candy production lines cover a variety of sizes and models, designed to adapt to different production spaces and process requirements. For precise matching of your production scale, please feel free to contact us for a customized consultation solution.

| Model | GD-150 | GD-300 | GD-450 | HQ-600 |

| Standard Production Volume(kg/hour) | 150 | 300 | 450 | 600 |

| The Sugar Weight | 2-6g | |||

| Pouring Rate | 30-35n/min | 45-55n/min | ||

| Work Environment Requirements | Temperature:20-25℃ Humidity :55% | |||

| Overall Weight | 3800kg | 4000kg | 4500kg | 5000kg |

Gummy Candy Production Line Applications

Multiple Product Applications for the Gummy Candy Production Line

Relying on precise cooking and depositing processes, this system is ideal for producing classic gelatin or pectin-based candies. Whether in playful gummy bear shapes or simple geometric forms, the finished products feature excellent transparency and elasticity with a firm texture and uniform flavor release, perfectly suited for retail and gift markets.

Specially designed for consumers seeking a rich mouthfeel, this process precisely encapsulates rich fruit jams, smooth chocolate, or sweet-and-sour liquid centers within the gummy. The unique combination of a resilient outer shell and a flowing core creates a crystal-clear visual appeal and delivers a multi-layered taste explosion the moment you bite into it.

Targeting the nutrition and health industry, this gummy candy production line supports precise temperature control for adding active ingredients. The resulting gummy shapes effectively retain nutrients and solve swallowing difficulties, making them popular in the mother and baby and youth markets.

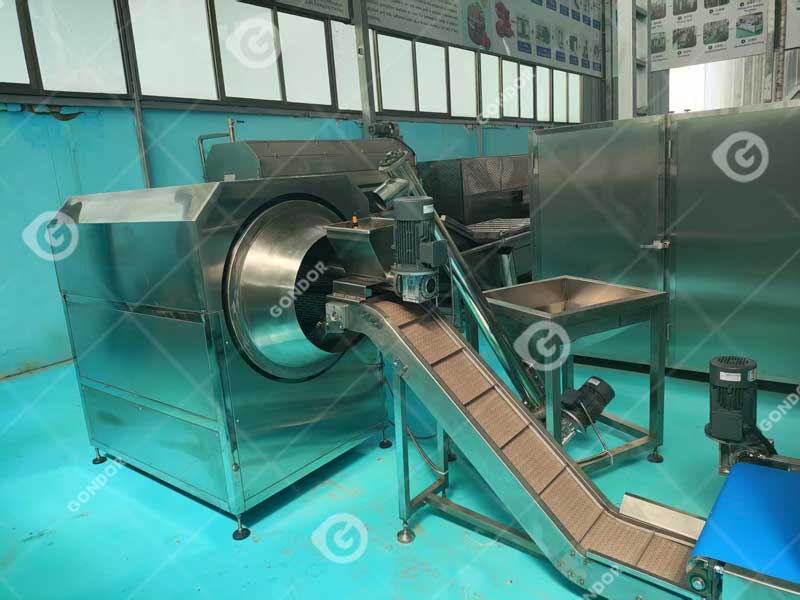

Through an efficient post-treatment system, a uniform layer of fine sugar or sour powder is applied to the gummy surface. The automated coating process ensures each candy is evenly covered without clumping, adding a gritty texture and a complex sweet-and-sour profile while effectively preventing sticking in high-temperature or humid environments.

Industrial Applications of Gummy Candy Production Line

Perfect for large-scale manufacturers and boutique candy brands looking to produce premium gelatin or pectin gummies for the global supermarket and gift markets.

Trend An ideal solution for pharmaceutical and health supplement companies to develop “snack-styled” vitamins, minerals, and probiotics that cater to the modern wellness lifestyle.

Empowers beauty brands to create functional gummies enriched with collagen, hyaluronic acid, and herbal extracts, capturing the booming “inner beauty” market.

Tailored for brands requiring flexible production of trending products like melatonin or energy-boosting gummies, ensuring a rapid transition from concept to consumer.

How to Produce Pectin Gummies That Don’t Stick Without Using Wax

To produce pectin gummies that don’t stick without using wax, you can use these professional techniques:

1. MCT Oil Coating (Clean Label Alternative)

- Method: After demolding, lightly toss gummies with a small amount of MCT oil (Fractionated Coconut Oil).

- Advantage: It is liquid at room temperature, flavorless, and provides a sleek, non-stick barrier without the heavy “waxy” feel of carnauba.

2. Sugar or Acid Sanding

- Method: Roll the gummies in granulated sugar or a sugar-citric acid mix immediately after they reach a firm set.

- Advantage: The crystals create a physical barrier that prevents surface-to-surface contact.

3. Controlled Drying (Curing)

- Method: Place demolded gummies in a drying room with low humidity (30–35% RH) for 24–72 hours.

- Advantage: This allows the gummy to develop a thin, dry “skin” through moisture evaporation, which naturally reduces tackiness.

4. Cornstarch Dusting

- Method: Lightly coat the gummies with a fine layer of cornstarch or tapioca starch.

- PH Level: Maintain a pH between 3.2 and 3.5 to ensure the pectin sets firmly; a weak gel is often the primary cause of stickiness.

5. Precise Formulation

- Brix Level: Ensure your syrup is cooked to a high solids content (78–82 Brix) to minimize free water.

- Advantage: It effectively absorbs excess surface moisture for a matte, non-sticky finish.

Gummy Candy Production Line Features

- High-Precision Depositing: Error<1%, ensuring consistent weight and uniform shape for every gummy.

- Versatile Production: Highly flexible, easily switching between gelatin, pectin, and functional recipes.

- Smart Changeover: Recipe and mold switching in as little as 30 minutes via intelligent presets.

- Flawless Demolding: Dual pneumatic systems ensure smooth release even for complex 3D shapes.

- Scalable Capacity: Modular expansion supports capacity growth from 200kg/h up to 3000kg/h.