High-efficiency Horizontal Chicken Breast Slicer

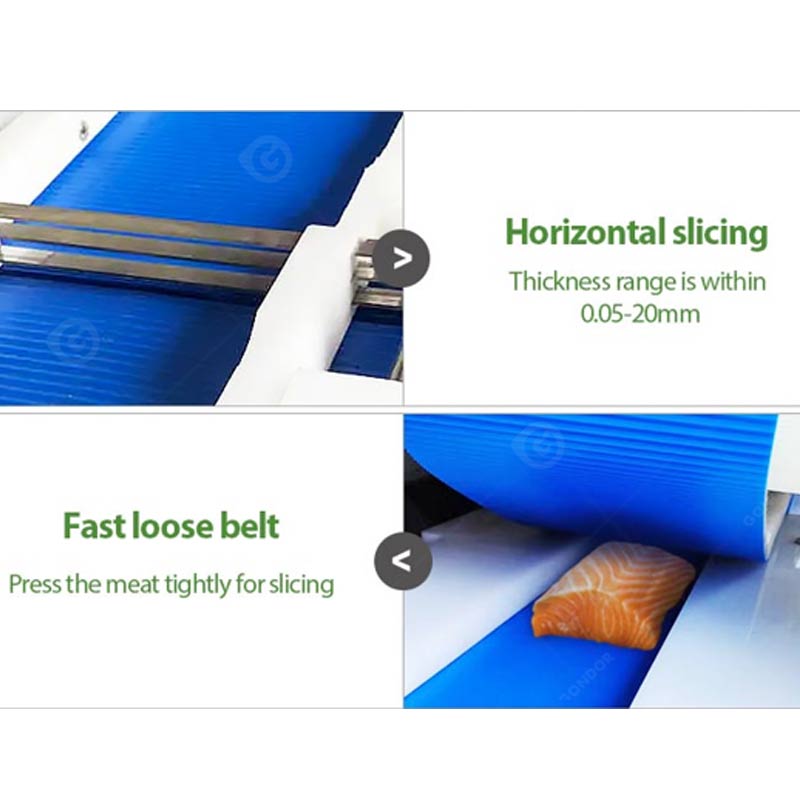

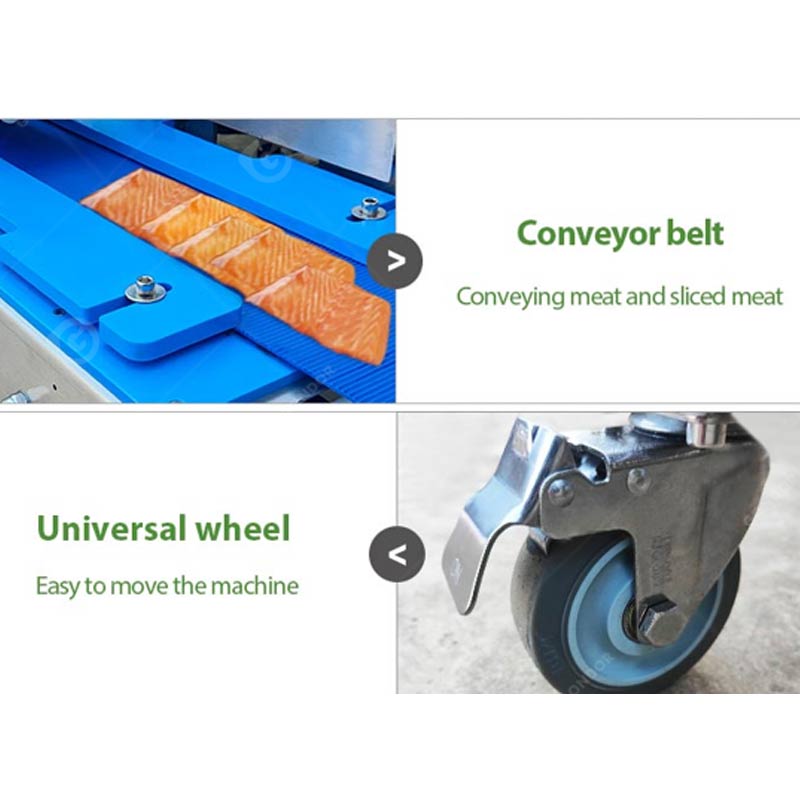

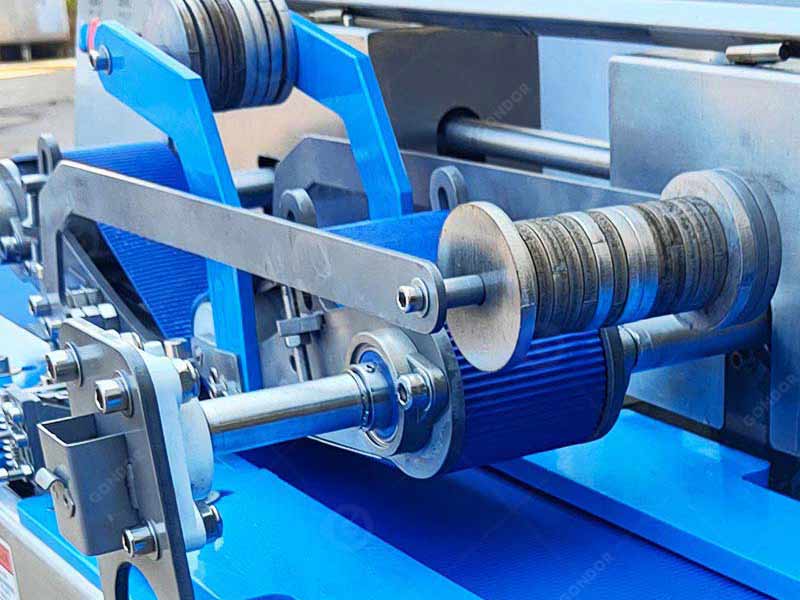

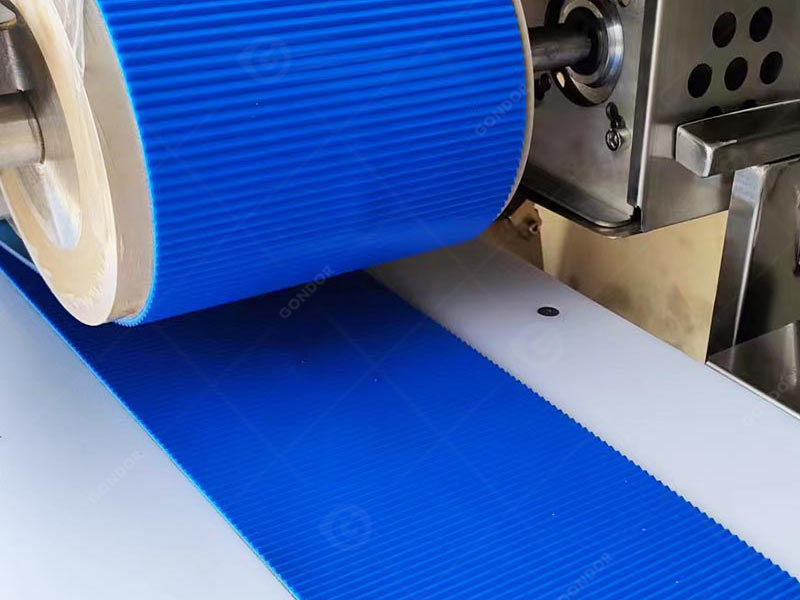

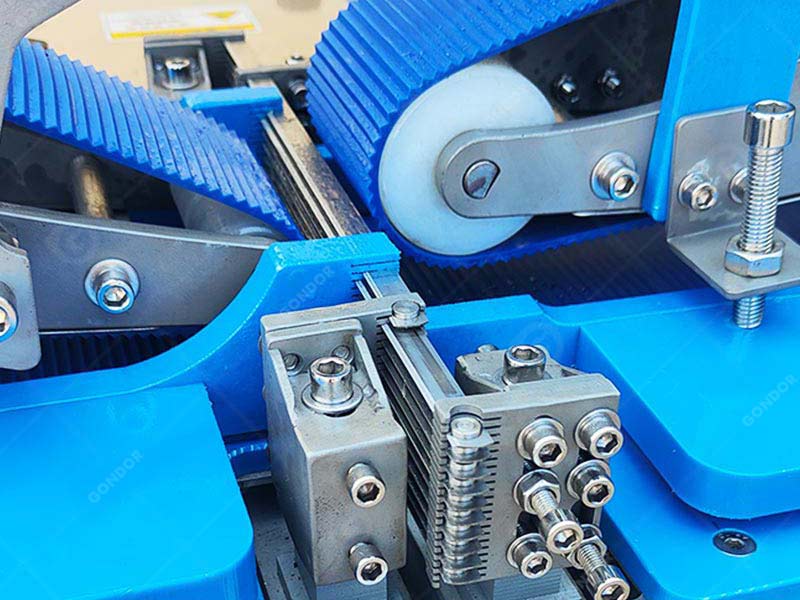

As a popular meat processing machinery, horizontal chicken breast fillet slicer machine is designed for high-efficiency slicing with precision and consistency. For instance, our horizontal meat slicer uses advanced technology to accurately slice fresh meat into uniform thin slices, which can meet the demands of both gourmet food preparation and large-scale food processing. What’s more, we design our chicken fillet slicer machine with user-friendliness in mind, so it is easy to operate and get started, thus greatly improving work efficiency and having a high output.

Additionally, Gondor machinery atopts the sturdy and durable material, which can ensures long-term stable operation and a prolonged service life. With its ability to effortlessly process fresh meat, this slicer brings exceptional convenience to your operations. Whether for commercial kitchens or food manufacturing facilities, it is undoubtedly the ideal solution for those seeking efficient, reliable, and high-quality meat slicing. Contact us for more details!

GD-500

GD-400

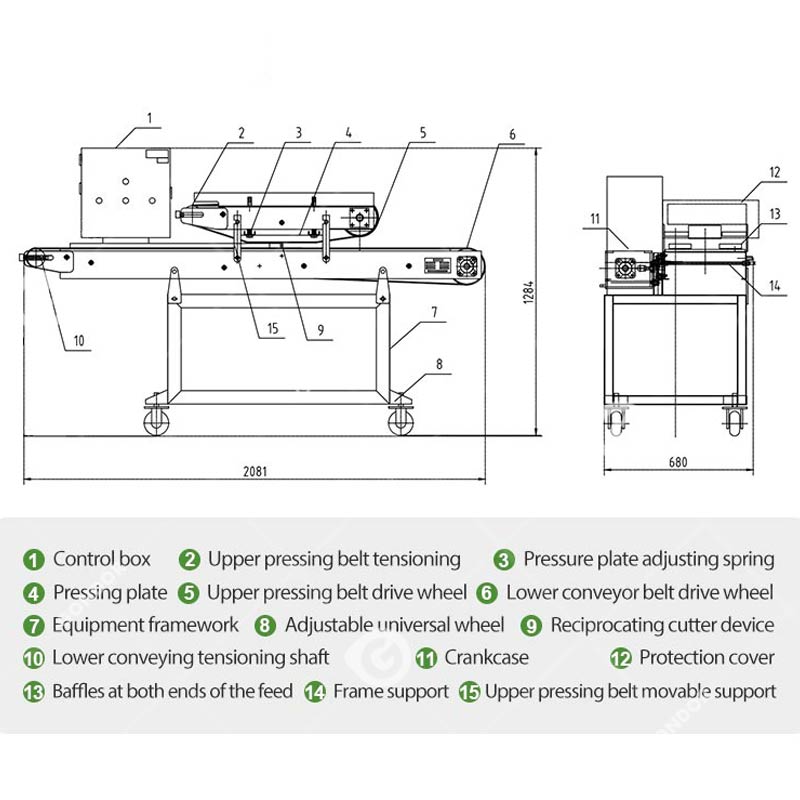

Chicken Breast Horizontal Slicer Specification

| Model | GD-400 | GD-500 |

| Capacity | 400-500kg/h | 500-700kg/h |

| Power | 2.25kw | 1.65kw |

| Cutting thickness | 0.05-20mm | 2.5-20mm |

| Size | 2000*950*1230mm | 2100*680*1300mm |

| Weight | 450kg | 300kg |

Main Application Market Scope of Gondor Horizontal Meat Slicer

As consumer standards continue to rise, so does the demand for clean, evenly sliced meat in every setting, from hot pot chains to frozen food manufacturers. Manual slicing simply can’t keep up with today’s pace or precision requirements. That’s why more businesses are turning to professional slicing equipment like the Gondor chicken breast slicer machine. Whether you’re slicing fresh pork for barbecue, chicken for stir-fry, or beef for hot pot, this machine ensures each piece is consistent in thickness and presentation. More importantly, it reduces prep time drastically and minimizes product waste. That means less labor, fewer mistakes, and more time focused on serving or selling your product.

Various fresh meats can be cut into slices of specific thickness, which is convenient for making ham, sausage, etc. and improves processing efficiency.

Fresh meat is cut into thin slices and quick-frozen to produce quick-frozen meat slices to meet consumers’ needs for fast cooking and expand product categories.

Hot pot restaurant uses this equipment to cut fresh meat into thin slices, which makes it more convenient for customers to cook, greatly improving the dining experience.

Cut fresh meat into uniform thin slices for easy baking, ensuring the taste and quality of barbecue, and attracting more diners to taste.

In Chinese restaurants, some Chinese dishes require thin slices of meat, which can quickly meet the needs of chefs and ensure the quality and speed of dishes.

Provide customers with fresh meat slices to meet consumers’ needs for cooking at home, increase the variety of goods, and improve customer satisfaction.

Butchers in farmers’ markets can provide customers with customized meat slices to meet the needs of different customers and increase their competitiveness.

Built for Performance — Key Advantages of the Gondor Chicken Breast Slicer Machine

The Gondor horizontal meat slicer isn’t just another piece of food processing equipment, and it’s a thoughtfully engineered solution that combines performance, reliability, and hygiene. Crafted for commercial kitchens and production lines alike, this chicken breast slicer machine delivers the kind of precision and speed that today’s food industry demands. Below are the core advantages, expanded in real-world context to help you understand how each feature adds value to your operations — whether you’re a butcher, food producer, or kitchen manager.

Essential Considerations Before Buying a Horizontal Meat Slicer

Choosing the right horizontal meat slicer isn’t just a matter of ticking boxes—it’s about finding a machine that truly fits your production needs, operational style, and long-term goals. With the market offering a wide range of models and features, it’s important to go beyond surface specs and dig into the details. Here are several practical, experience-based tips to help guide your decision.

Gondor Machinery: Your Trusted Innovator in Poultry Slicing Technology

At Gondor Machinery, we don’t just manufacture food processing equipment—we engineer intelligent solutions tailored for modern poultry processing lines. Backed by years of experience and a strong commitment to innovation, we combine advanced technology with thoughtful design to help food producers meet evolving industry demands with greater precision and efficiency. In the realm of poultry slicing machinery, we’ve developed a full range of equipment that balances hygiene, performance, and usability. By continuously improving our structural designs and adopting premium-grade stainless steel, we ensure each machine operates reliably and complies with the highest food safety standards. Furthermore, intelligent parameter control systems allow for seamless operation and finely tuned adjustments, even under high-capacity workloads.

Here’s what sets our poultry slicing machines apart:

Gondor chicken fillet slicer machine leads the new trend of efficient slicing!

Are you still worried about the time-consuming and laborious slicing of fresh meat? Well, now, Gondor Horizontal chicken breast fillet slicer machine brings you a brand new solution! For one thing, it has efficient and accurate slicing performance. Thus, it can cut fresh meat into uniform and beautiful slices in a very short time, greatly improving work efficiency. For another, it adopts high-quality materials and advanced technology. Therefore, it is safe, reliable and of excellent quality. No matter whether it is a food processing enterprise or a catering place, Gondor chicken fillet slicer machine is undoubtedly your excellent helper!