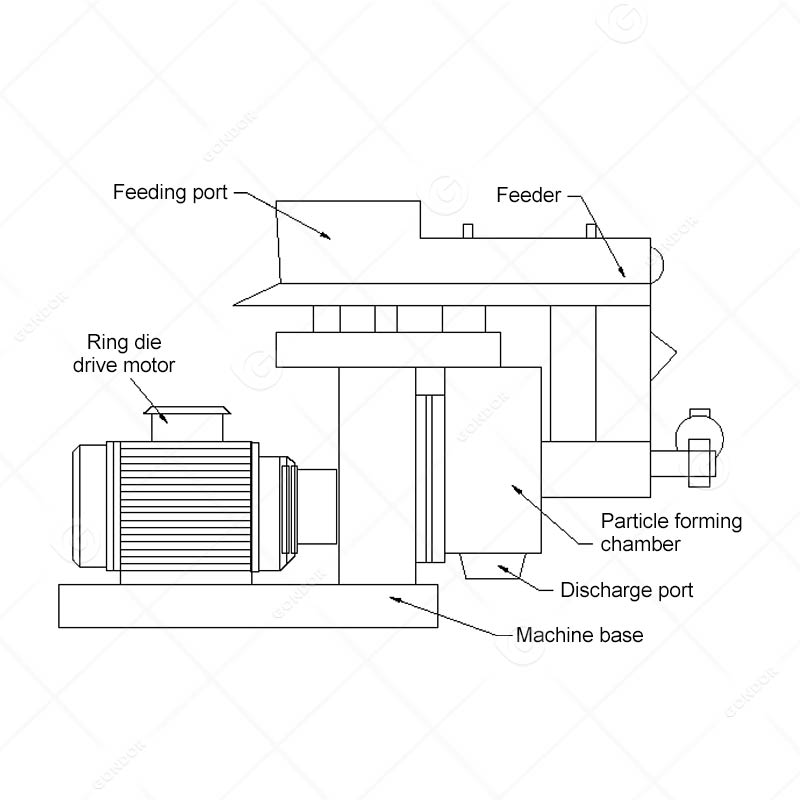

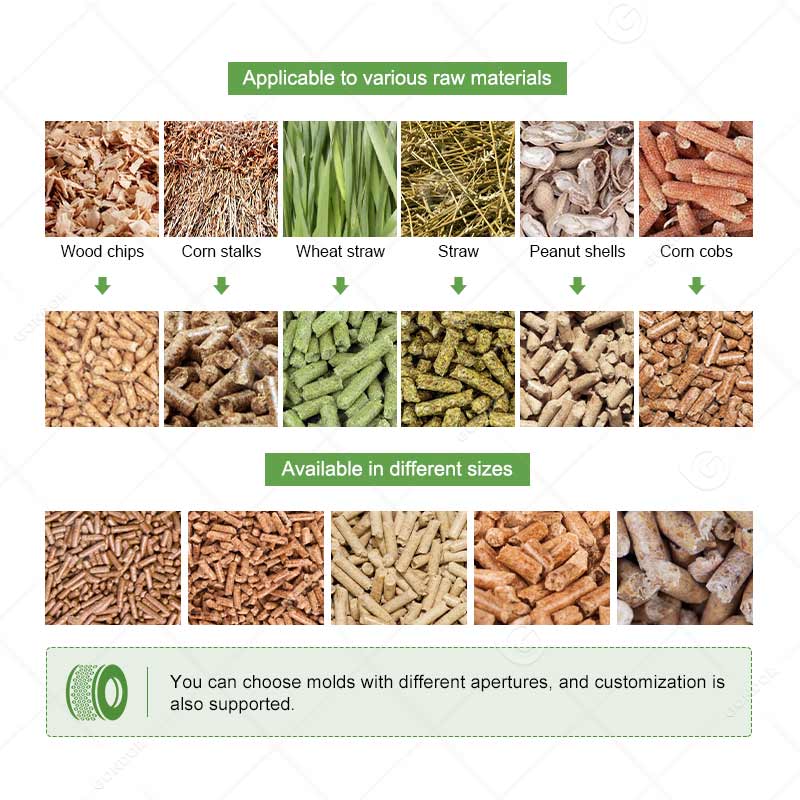

The horizontal ring die biomass pellet mill is an efficient, durable and environmentally friendly equipment that can process agricultural and forestry waste such as wood chips, straw, rice husks, peanut shells, etc. into high-density biomass fuel pellets. It adopts a high-precision gear transmission system to ensure stable production, high pellet combustion efficiency, and easy storage and transportation. Equipped with high-strength molds, high-efficiency motors, imported bearings and other core components, it is widely used in biomass power plants, fuel processing plants, chemical plants and boiler fuel supply, helping to save energy and reduce consumption and improve fuel utilization.

|

Capacity |

Size | Weight | Packing Size |

Packing Weight |

|

1-1.5t/h |

2500*900*1980mm | 2000kg | 2650*1000*2100mm | 2150kg |

| 1.5-2t/h | 2700*1250*2000mm | 3500kg | 2850*1350*2150mm |

3680kg |

|

2.5t/h |

3000*1400*2500mm | 4000kg | 3200*1500*2650mm | 4200kg |

Applicable Market of Horizontal Ring Die Biomass Pellet Mill

As a clean energy, biomass fuel has received widespread attention worldwide in recent years, especially in countries and regions with strict environmental protection policies such as Europe, North America, and Southeast Asia. Biomass pellet fuel is gradually replacing traditional coal. Horizontal ring die biomass pellet machine has been widely used in the following industries due to its high efficiency, energy saving, and low emission characteristics:

Product Advantages of Wood Pellet Mill Machine

The high-precision gear transmission (Precision Gear Transmission) improves the efficiency by nearly 20% compared with the traditional belt transmission, ensuring stable and efficient operation and reducing energy consumption.

It can process a variety of biomass raw materials, including wood chips, straw, peanut shells, bamboo sawdust, coconut shells, etc. One machine has multiple uses and is economical and applicable.

The horizontal ring die design makes the whole machine compact and occupies a small area, which is convenient for plant layout and production line planning, and is suitable for pellet production companies of all sizes.

The dual-press wheel ring die (Dual-Press Wheel Ring Die) has stronger wear resistance, reduces the cost of frequent die replacement, and ensures long-term stable production.

Imported bearings and low-noise oil seal system are used, and flexible coupling is equipped to reduce impact, making the equipment more stable and reducing maintenance costs.

Equipped with a lubrication port, it effectively reduces equipment friction, extends machine life, reduces maintenance frequency, and improves production efficiency.

Recommended Related Equipment

In addition to the horizontal ring die biomass pellet mill, we also provide the following equipment to meet different production needs:

- Vertical Ring Die Biomass Pellet Machine – Suitable for high-capacity continuous production.

- Automatic Packing Machine – Improve production efficiency and conveniently package pellet fuel.

If you are looking for an efficient, durable and energy-saving biomass pellet machine, please contact us! We provide customized solutions to meet your specific needs and help you succeed in the field of biomass energy! Contact us for detailed quotes and technical support!