Gondor Ice Cream Cone Cup Filling Machine

Ice cream cone cup filler machine is ideal for filling various ice creams such as ice cream with latte art, rotating art, crisp cone, round square cup and various cup-shaped ice creams. It utilizes advanced technology and design, allowing for the fast and accurate injection of ice cream into different containers.

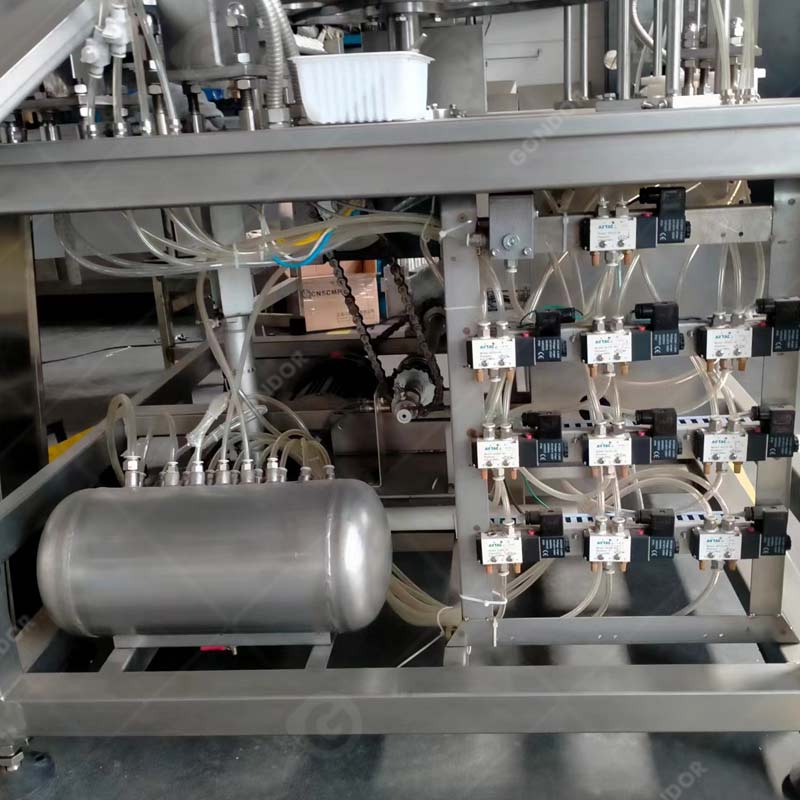

Moreover, this machine typically features a high degree of automation, simple operation, and precise filling accuracy. It can be easily adjusted to meet different needs, adapting to containers of various sizes and shapes. Additionally, the machine incorporates a touch screen display and PLC automatic control system, enabling the presetting and storage of production color programs for different ice cream varieties.

Ice Cream Cone Cup Filler Machine Specification

|

Model |

Capacity | Unit filling weight | Voltage | Power | Air consumption | Use pressure |

Size |

|

GD-16A |

600L/h | 50-150 g/cup | 380v-50hz | 2.5kw | 0.8m³/min | 0.5-0.6 (mpa) | 1350x1120x1700mm |

| GD-4B | 1200L/h | 50-200 g/cup | 380v-50hz | 4.5kw | 1.3m³/min | 0.5-0.6 (mpa) |

4800x900x2000mm |

|

GD-6A |

1200-2400L/h | 50-200 g/cup | 380v-50hz | 6.2kw | 1.9m³/min | 0.5-0.6 (mpa) | 4800x1200x2000mm |

| GD-8L | 8000-21000cup/h | 20-500 g/cup | 380v-60hz | 4.5kw | 1.2m³/min | 0.5-0.6 (mpa) | 5600x1140x2400mm |

|

GD-12 |

12000-25000cup/h | 20-200 g/cup | 380v-60hz | 6.2kw | 1.9m³/min | 0.5-0.6 (mpa) | 4800x1140x2000mm |

Application Market Scope of Gondor Ice Cream Cone Filling Machine

It can efficiently and accurately fill ice cream of different flavors into various packaging containers to meet large-scale production, improve efficiency and quality stability.

Suitable for the production and packaging of various beverages in the beverage industry, ensuring efficient filling and providing stable production support for fruit juice, tea drinks, etc.

In the dairy production line, Gondor filling machine helps to fill milk, yogurt and other products, improving production efficiency and quality.

Frozen desserts such as frozen yogurt can use this filling machine, which can be adjusted according to product characteristics to ensure accurate and consistent filling.

The filling machine can meet the production and packaging needs of gel desserts such as jelly and pudding, and adapt to different forms and specifications.

Used for packaging of condiments such as salad dressing, both fluid and semi-fluid, to meet the filling needs of the condiment industry.

Quantitative filling of drinks and sauces for restaurant chains and central kitchens to improve food processing efficiency.

Help produce packaging that meets international standards, enter the world, and meet the market demand for portable food and beverages.

Excellent Performance Advantages of Gondor Ice Cream Cup Filling Machine

Gondor Ice Cream Cone Cup Filler Machine – Efficient Filling, Enjoy the Coolness

The Gondor ice cream filler stands out for its advanced technology, precise filling, and high automation, making it a top choice for ice cream manufacturers. With its multi-channel filling function, it can fill multiple containers simultaneously, significantly improving production efficiency. Additionally, the machine’s flexible adjustment and intelligent control system allow it to adapt to containers of various shapes and sizes, meeting diverse market needs. What’s more, it is also easy to operate and maintain, helping businesses boost production capacity and ensure consistent product quality. Choose Gondor to effortlessly tackle production challenges, capture market opportunities, and enhance competitiveness.