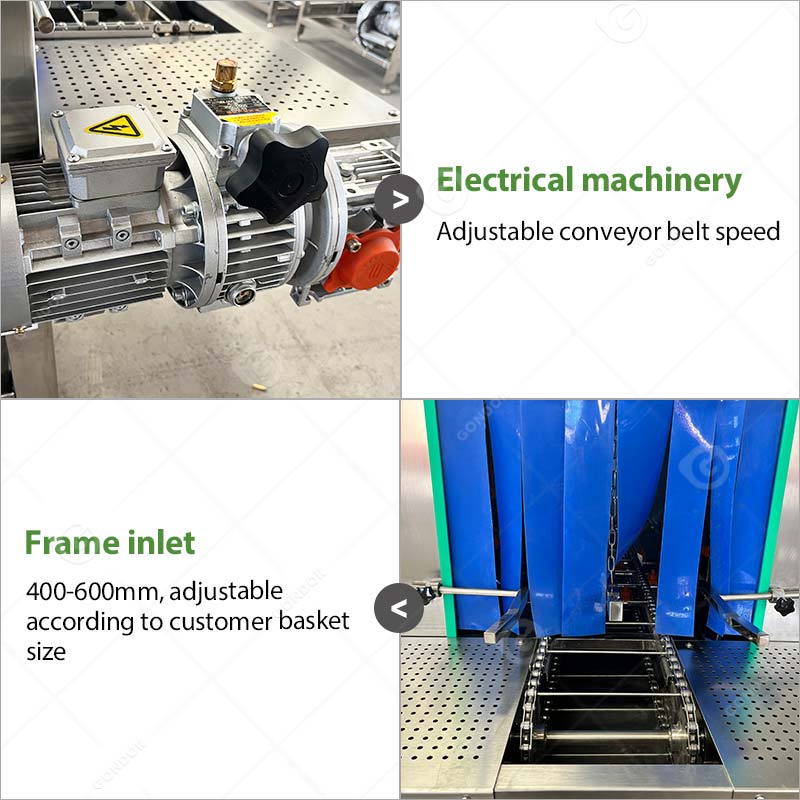

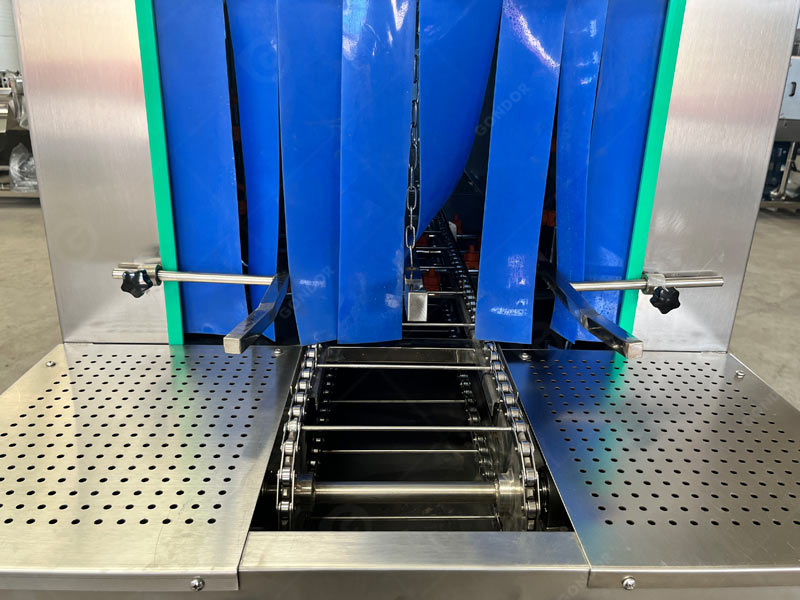

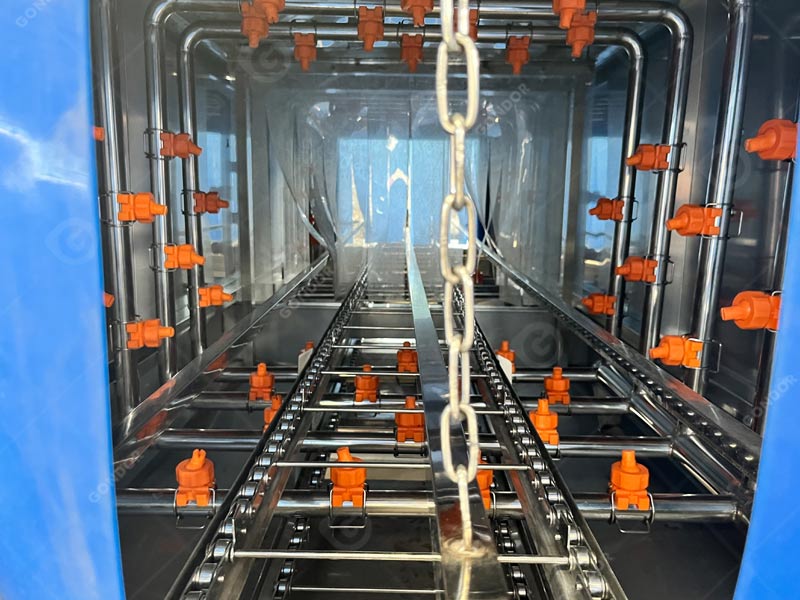

Industrial crate washer machine is an efficient, hygienic, and easy-to-operate cleaning device, which is widely used in industries such as frozen food processing plants, hotels, pickle processing plants, and seafood processing facilities. It is constructed from food-grade 304 stainless steel, which provides a beautiful appearance, easy cleaning, and compliance with food hygiene standards. The equipment ensures thorough cleaning through an intelligent temperature control system and four-sided high-pressure nozzles. Additionally, it is equipped with an adjustable conveyor chain and a circulating water tank, which helps save water resources and reduce labor input. Moreover, the basket washer supports customized lengths, and drying equipment can be added based on customer needs, thereby greatly improving cleaning efficiency. Thus, it is an ideal choice for modern cleaning operations.

| Model | GD-BBWM-3000 |

| Voltage | 220/380V/50Hz |

| Power | 12kw |

| Material | 201 |

| Machine size | 3000*1400*1700mm |

| Net weight | 300kg |

Markets Targeted by Gondor Plastic Crate Washer Machine

As an efficient and hygienic cleaning equipment, crate washers are suitable for a variety of industries and markets. They can meet the high standards of cleaning and disinfection required by different types of enterprises, especially those involving food processing and turnover equipment cleaning. The following are the main application markets for basket washing machines:

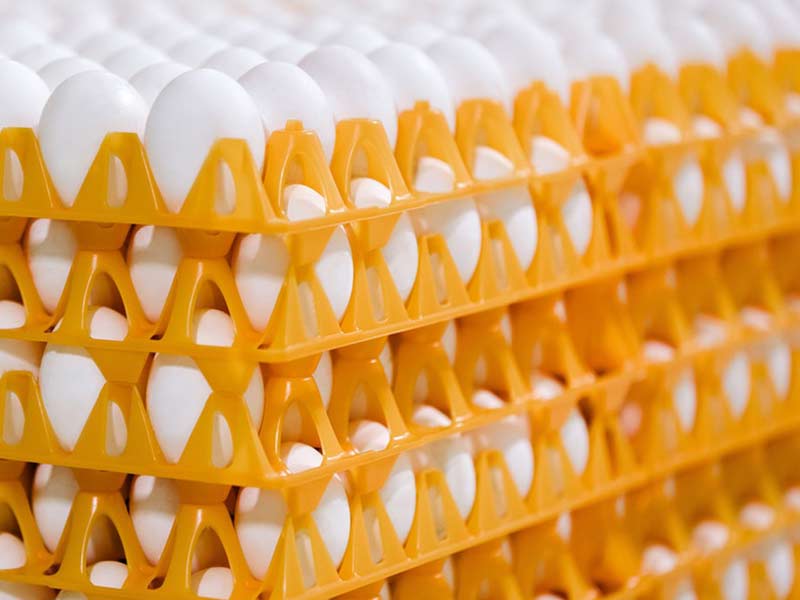

A large number of turnover baskets used for food transportation and storage need to be cleaned to ensure hygiene and safety standards.

Containers and turnover baskets used for fermentation and processing are cleaned to prevent bacterial growth and ensure product quality.

Cleaning turnover baskets for products such as fish and shellfish to prevent odor and contamination and keep the processing environment clean.

Storage baskets for fruits and vegetables undergo cleaning to remove stains and impurities, ensuring hygiene throughout the processing process.

Transportation and storage baskets for poultry like chickens and ducks are cleaned to reduce germ spread and promote a healthy breeding environment.

Used to clean the storage and transportation baskets of slaughtered meat to prevent bacteria growth and meet hygiene standards.

Milk and cheese storage containers are cleaned to avoid secondary contamination during dairy product production.

Turnover containers for bottled and canned beverages are cleaned to ensure that the production process complies with food safety regulations.

Significant Working Advantages of Gondor Industrial Crate Washer

Choose Gondor Crate Washer to Boost Your Cleaning Efficiency

The Gondor industrial crate washer machine offers an ideal solution with its outstanding cleaning performance and high energy efficiency, making it perfect for industries such as frozen food, hospitality, seafood, and fruit and vegetable processing. Constructed from food-grade 304 stainless steel, it ensures the highest standards of hygiene and safety. Moreover, its four-sided high-pressure nozzles, combined with an intelligent temperature control system, guarantee that each turnover basket is thoroughly cleaned. Additionally, the automated design reduces labor costs, while the circulating water system conserves water. Furthermore, the washer supports customizable lengths and the option to add drying equipment, delivering a tailored cleaning solution to meet your specific needs. Fill in the inquiry box below now to receive more details and a personalized quote!