Industrial onion peeling and cutting machine is a highly efficient equipment specially used for processing onions in large quantities. It is mainly composed of a feed port, a peeling device, a rooting device, a conveying system and other parts. Moreover, onions in any state can be peeled at one time without special requirements. In addition, the machine is easy to operate, greatly improves the efficiency of onion processing, reduces the intensity of manual labor, and ensures that the processed onions are clean and neat, providing convenience for food processing companies and the catering industry.

|

Model |

Voltage | Size(mm) | Weight | Capacity |

| GD-OOPM1 | 380V 1.52KW | 2050x1060x1960 | 286KG |

45 PCS/MIN |

|

GD-OOPM2 |

380V 1.15KW | 2220x1200x1950 | 300KG | 1-1.5T/H |

| GD-OOPM3 | 380V 1.52KW | 2150x1150x2000 | 300KG |

2-2.5T/H |

|

GD-OFTM1 |

380V 1.11KW | 3000x830x1500 | 203KG | 50-60 PCS/MIN |

| GD-OFTM2 | 380V 2.22KW | 2600x1400x1400 | 350KG |

100 PCS/MIN |

Main Application Market Scope of Gondor Industrial Onion Peeling Machine

It can quickly remove the skin and roots of onions, ensure the purity of raw materials in the subsequent production of onion powder, onion sauce and other products, and improve the taste and quality of the products.

In a comprehensive vegetable processing plant, it can be used in conjunction with other vegetable processing equipment to realize an automated vegetable processing production line. Improve production efficiency and reduce labor costs.

Quickly process a large number of onions as cooking ingredients, saving chefs’ time and energy and improving kitchen work efficiency. It also ensures the cleanliness and consistency of onions.

Fast food chains have high requirements for the processing speed of ingredients. Onion peel machines can quickly provide a large number of processed onions to meet the needs of fast food production.

The equipment can process onions at the wholesale stage and provide retailers with better quality products. Increase onion sales and meet consumers’ demand for convenient and fast ingredients.

Help e-commerce platforms process onions, provide consumers with high-quality fresh food ingredients, improve consumers’ shopping experience, and increase the competitiveness of e-commerce platforms.

Significant Working Advantages of the Gondor Onion Peeling and Cutting Machine

Automatically and efficiently complete the peeling and rooting of onions in a short time, peeling and cutting cleanly with high efficiency. It can meet the needs of large-scale production and processing, and bring higher economic benefits to the enterprise.

This equipment has good continuous operation capability and does not require frequent shutdown for adjustment or maintenance, ensuring the continuity and stability of production. Suitable for onion processing enterprises and food production sites of various scales.

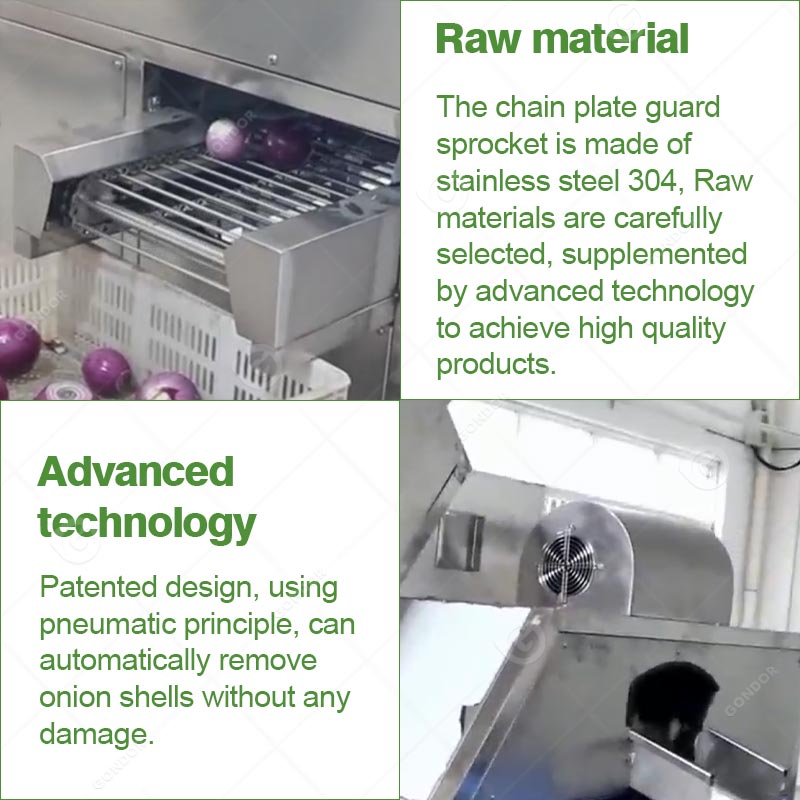

The pneumatic principle is adopted for knifeless peeling. The peeled onions are not damaged, the appearance is perfect, and the internal tissue of the onions will not be damaged. Ensure the integrity and quality of the onions.

Traditional onion peeling and rooting work requires manual work, which is easy to cause injuries, such as cuts, irritating eyes, etc. The use of equipment can reduce the risk of manual operation and protect the health of workers.

Made of 304 stainless steel, the raw materials are carefully selected, supplemented by advanced technology, with stable performance and reliable operation. It is less prone to failure, which reduces the cost of equipment repair and maintenance.

Energy-saving technology is usually used, consuming less energy. Compared with traditional processing methods, it is more energy-saving and environmentally friendly, and meets the requirements of modern society for sustainable development.

Gondor Industrial Onion Peeling and Cutting Machine – Efficient Choice

Gondor industrial onion peeling and cutting machine can quickly and accurately remove the onion skin and roots, greatly improving work efficiency. It is easy to operate and saves labor costs. Ensure that the onions are handled cleanly and neatly, and improve product quality. Whether it is a dehydrated vegetable factory or a catering company, Gondor onion peeling and rooting machine is your right-hand man. Come and buy it to help your business develop efficiently.