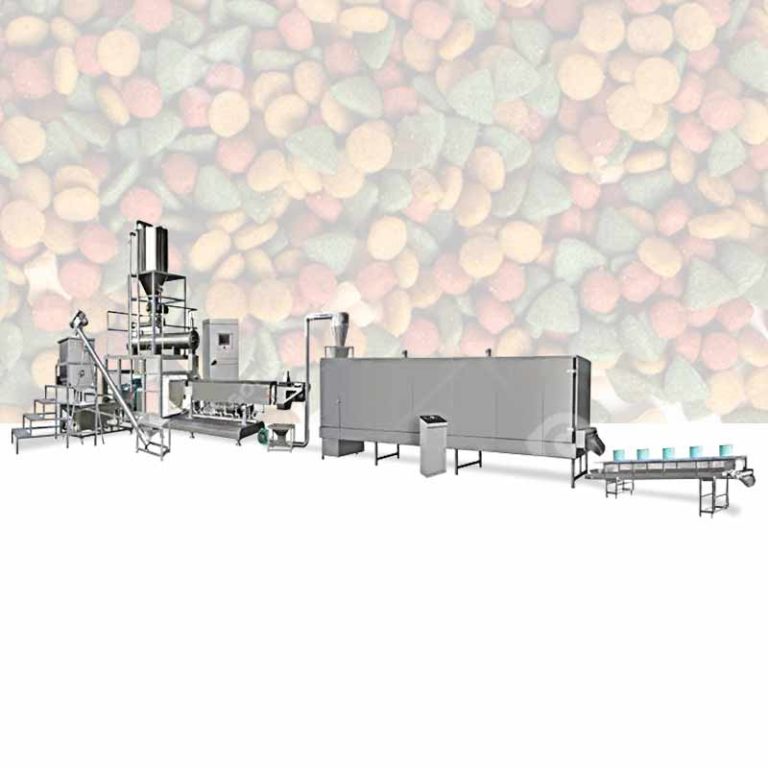

Your Complete Solution for Premium Pet Food Making Machine

Pet dog food extruder making machine is a critical piece of equipment specially designed for manufacturers aiming to produce high-quality, nutritious, and consistent pet food products. Among these, the pet food extruder plays a central role in shaping, cooking, and enhancing the nutritional value of pet food — especially for dogs. What’s more, the pet dog food extruder making machine is an all-in-one solution for pet food manufacturers looking to deliver consistent, nutritious, and high-quality food. Combining efficiency, hygiene, advanced automation, and customization, it stands as an indispensable tool in the modern pet food industry. Contact Gondor machinery to achieve sucess in the dog food project!

What Is a Pet Food Extruder and How Does It Work?

A pet food extruder is a highly specialized machine designed for the production of dry pet food products such as dog kibble and cat food. By combining mechanical pressure, heat, and controlled moisture, this equipment transforms raw ingredients into uniformly shaped, cooked, and shelf-stable food pellets. It is a key component in modern pet food making machines, especially in large-scale, automated production lines.

In addition, the product outlet is equipped with a variable frequency speed regulating rotary cutting device, which can adjust the blade rotation speed at will to control the speed and length of cutting. Besides, this machine has the characteristics of high output, stable operation, high wear resistance and long service life. What’s more, it can also adjust the processing parameters according to different formulas and requirements to produce pet food of various shapes and tastes, such as granules, strips, etc.

Check the extrusion process consists of several critical steps:

Feeding

Raw materials such as grains, meat meals, vitamins, and minerals are fed into the extruder through a hopper.

Pre-Conditioning

The material is sometimes pre-conditioned with moisture and heat to soften it before entering the barrel.

Mixing and Conveying

Inside the extruder barrel, rotating screws convey the material forward while continuously mixing it.

Heating and Compression

As the material moves forward, it is subjected to increasing pressure and temperature due to the design of the screws and the external heating zones.

Cooking and Transformation

Under high temperature and pressure, starches gelatinize, proteins denature, and fats melt. This biochemical transformation makes the food more digestible and safe for consumption.

Shaping and Expansion

The molten mixture is forced through a die at the end of the extruder. As it exits the die, the sudden drop in pressure causes the internal moisture to vaporize rapidly—this is known as instant expansion or flash puffing.

Cooling and Drying

The extruded product is then dried and cooled to reduce moisture content and improve shelf stability.

| Model | Productivity (t/h) | Host power (kw) | Feeding power(kw) | Spiral diameter(mm) | Cutting power

(kw) |

Packing size | Weight |

| GD-PDFM-40 | 0.04-0.05 | 5.5kw(220v) | 0.4 | Φ40 | 0.4 | 1.36*1.60*0.85m | 350kg |

| GD-PDFM-50 | 0.08-0.09 | 11kw(380v) | 0.4 | Φ50 | 0.4 | 1.36*1.60*0.85m | 350kg |

| GD-PDFM-60 | 0.12-0.15 | 15 | 0.4 | Φ60 | 0.4 | 1.36*1.67*0.85m | 450kg |

| GD-PDFM-702 | 0.18-0.20 | 18.5 | 0.4 | Φ70 | 0.4 | 1.36*1.67*0.85m | 490kg |

| GD-PDFM-703 | 0.20-0.25 | 18.5 | 0.4 | Φ70 | 0.4 | 1.36*1.67*0.85m | 490kg |

| GD-PDFM-80 | 0.3-0.35 | 22 | 0.55 | Φ80 | 0.55 | 1.36*1.95*0.84m | 600kg |

| GD-PDFM-100 | 0.4-0.5 | 37 | 1.1 | Φ90 | 1.5 | 1.8*2.6*1.15m | 800kg |

| GD-PDFM-120 | 0.60-0.70 | 55 | 1.1 | Φ120 | 2.2 | 2.2*2.8*1.2m | 950kg |

| GD-PDFM-135 | 0.75-0.8 | 75 | 1.1 | Φ133 | 2.2 | 2.2*2.8*1.2m | 950kg |

| GD-PDFM-160 | 1.0-1.2 | 90 | 1.5 | Φ160 | 2.2 | 2.3*3.0*1.2m | 1200kg |

| GD-PDFM-200 | 1.8-2.0 | 110 | 2.2 | Φ160 | 2.2 | 2.4*3.2*1.4m | 1450kg |

Wide Application Market of Gondor Pet Food Making Machine

The Gondor pet food making machine is more than just a piece of industrial equipment, and it’s a flexible and intelligent solution which is designed to serve the evolving needs of the global pet food industry. With the ability to handle diverse ingredients and formulations, this equipment adapts seamlessly to a variety of production scenarios. Whether targeting domestic pet owners, specialized nutrition markets, or export-oriented demands, Gondor’s technology supports innovation, consistency, and quality across every segment. Below are some of the key application areas where Gondor machines deliver outstanding performance and value:

Dog Food Production

Gondor machines produce a wide variety of dog food types and flavors, tailored to different breeds and life stages.

Cat Food Production

Ideal for making high-protein, highly palatable cat food that meets both nutritional and taste preferences.

Fish Food Production

Capable of producing floating or sinking fish feed with adjustable density for various aquatic species.

Bird Pet Food

Supports the production of pellets or mixed feed to suit the dietary needs of different pet birds.

Pet Staple Food Market

Enables consistent, high-quality staple pet food production for building long-term brand trust.

Other Terrestrial Pet Food

Suitable for producing fiber-controlled feed for small pets like hamsters, rabbits, and guinea pigs.

Export Trade

Adaptable to different international standards, making it ideal for global pet food export markets.

Pet Food Processing Enterprises

Helps small to medium manufacturers enhance automation and ensure consistent product quality.

Pet Feed Factory

Supports high-capacity, multi-formula production in large-scale pet feed manufacturing facilities.

Pet Snacks

Allows for the creation of diverse pet treats such as chews, biscuits, and freeze-dried snacks.

Significant Functional Characteristics of Pet Food Extruder

Wht’s more, Gondor pet food extruder is not only a core component in modern pet feed processing but also a symbol of reliability, precision, and innovation. Engineered with advanced extrusion technology, the machine integrates multiple high-performance features that improve both product quality and operational efficiency. From smart control systems to durable materials and hygienic design, every detail is tailored to meet the practical needs of professional pet food manufacturers.

The extruder allows accurate regulation of feed density for both pet and aquatic feed, which improves feeding efficiency while ensuring animals receive consistent and balanced nutrition.

By utilizing a dry puffing method that relies on self-heating, the system eliminates the need for external steam. This approach not only saves energy and reduces environmental impact, but also enhances overall production speed and simplicity.

The specially designed screw structure features a self-cleaning mechanism that helps prevent residue buildup and bacterial growth, maintaining hygiene and reducing downtime between production batches.

A variable-speed cutting system enables precise adjustment of the gap between the blade and the die plate, allowing for quick customization of pellet size and shape to suit different animal species and market demands.

The extruder boasts a compact layout and streamlined mechanical design, ensuring high throughput while minimizing footprint, perfect for both large-scale factories and space-conscious production environments.

Key components are made from high-strength alloy materials that have undergone heat treatment, offering exceptional wear resistance and extending the machine’s service life even under intensive use.

Customization & Flexibility in Dog Food Production

Gondor Machinery provides manufacturers with the flexibility to produce a wide range of dog food products that meet diverse nutritional requirements and market preferences. Our systems are engineered to adapt to various raw materials, control product characteristics precisely, and support multi-formula production, all with ease and efficiency.

Key Components of a Dog Food Making Machine Line

A high-performance dog food production line from Gondor Machinery is a complete system designed for precision, efficiency, and reliability. Each component plays a critical role, working together to streamline production and maintain quality throughout the process.

- Available in 100 kg/h to 1 ton/h capacity options

- Offers uniform cooking, thorough mixing, and high output consistency

- Central to shaping, expanding, and texturing the dog food

- Mixers: Ensure even blending of raw materials before extrusion

- Dryers: Reduce moisture content to improve shelf life and product stability

- Flavoring/Coating Systems: Enhance taste, aroma, and nutritional value through oil or powder application

- Full automation for multi-recipe management and real-time monitoring

- Precise adjustment of water, steam, and other process parameters

- Improves efficiency, reduces labor costs, and ensures product uniformity

Technology and Design Highlights from Gondor Machinery

At Gondor Machinery, we believe that outstanding pet food equipment begins with exceptional design and uncompromising engineering. Our extruders and supporting systems are built with precision, durability, and hygiene in mind—offering manufacturers both peace of mind and production efficiency.

Invest in Reliable Dog Food Making Equipment for Long-Term Success

Want to provide the best quality food for your pet? Choose Gondor pet dog food extruder making machine! It is powerful and can make a variety of delicious pet food. Whether it is dog food, cat food or pet snacks, our machine can be easily done. At Gondor Machinery, we bring together deep industry expertise and advanced engineering to deliver equipment that is durable, efficient, and fully customizable to your specific production goals. Whether you’re launching a new dog food line or scaling up existing capacity, our solutions are designed to grow with your business. Choose Gondor dog food making machine, start a pet food journey, and witness the happy growth of your pet together.