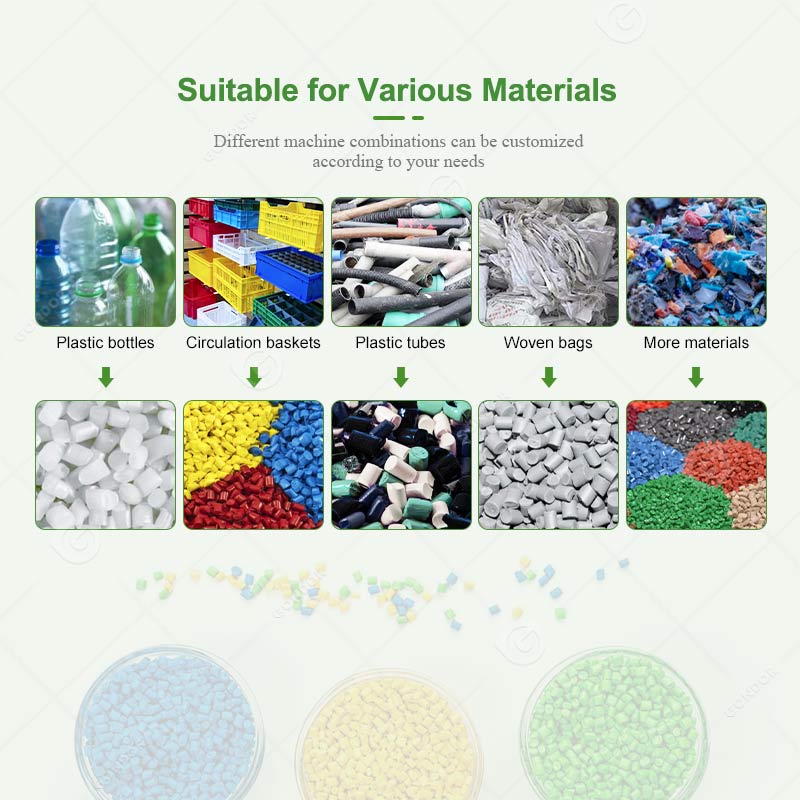

As the global demand for plastic recycling continues to grow, more and more companies and individuals are looking for efficient, environmentally friendly and economical solutions. Our plastic pelletizer machine is designed to meet this demand. It can recycle various plastic wastes such as plastic bottles and plastic scraps and reprocess them into high-quality plastic granules to achieve efficient reuse of resources.

|

Capacity

|

Power |

Size |

Weight |

Packing Size |

Packing Weight |

| 100kg/h |

85kw |

3300*1400*1450mm |

2000kg |

3500*1550*1600mm |

2260kg

|

|

350kg/h

|

143.6kw |

4000*1700*1700mm |

2500kg |

4150*1850*1820mm |

2800kg |

| 500kg/h |

194.4kw |

4500*1700*1800mm |

3000kg |

4650*1850*1930mm |

3350kg

|

Applicable Market of Gondor Plastic Pelletizer Machine

Home & Small Recycling CentersIndustrial Waste RecyclingPlastic Product Manufacturers

Applicable to small-scale plastic recycling, helping families or communities convert daily Plastic Waste into reusable pellets, which is both environmentally friendly and cost-saving.

Various factories will generate a large amount of Plastic Scraps during the production process. Our equipment can be directly recycled into reusable plastic pellets to reduce production costs.

By applying Recycled Plastic Pellets to the production of new plastic products, such as plastic pipes, plastic sheets, packaging materials, etc., a more economical and environmentally friendly production model can be achieved.

Technical Highlights of Gondor’s Plastic Granulator Machine

Fast Pelletizing Process

Through the High-Efficiency Screw Extrusion System, plastics can be melted and extruded in a short time, ensuring high output and fast molding.

Uniform Pellet Size

The Precision Cutting System is used to ensure uniform plastic pellet size, which helps the stability of subsequent processing and product quality.

Wide Material Compatibility

It can process a variety of plastics, such as PE, PP, PET, PVC, ABS, etc., making it suitable for multiple industries and different application scenarios.

Eco-Friendly & Energy-Saving Design

The equipment uses Low Energy Consumption Motors and Efficient Cooling Systems to reduce energy consumption and reduce carbon emissions.

Multiple Pelletizing Methods

- Water-Cooling Strand Pelletizing: Traditional pelletizing method, low equipment failure rate, suitable for most plastic materials.

- Water-Ring Pelletizing: Higher degree of automation, suitable for mass production, improves production efficiency.

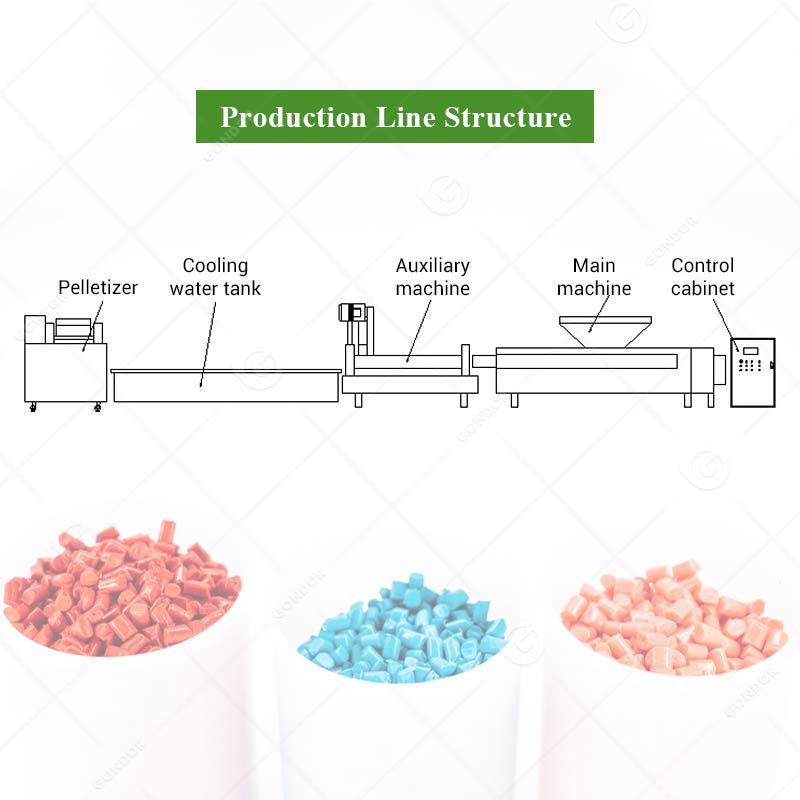

The Working Process of Small Plastic Pelletizing Line

FeedingMelting & ExtrudingCoolingPelletizing

Plastic waste is fed into the hopper through an elevator.

The plastic is heated and melted in the main machine, and then enters the auxiliary machine for further extrusion into strips.

The plastic strips are cooled and shaped through a water cooling tank.

The plastic strips enter the pelletizer and eventually form uniform plastic pellets.

Why Choose Our Plastic Pelletizer Machine?

- User-Friendly Operation: With high automation, ordinary workers can get started after simple training.

- Compact Design: Suitable for production environments with limited space, the equipment occupies a small area but has powerful functions.

- Cost-Effective: Compared with large equipment, the investment cost is low and the payback period is short, which is suitable for small and medium-sized enterprises and individual investors.

- Durable & Reliable: The body is made of 40Cr Alloy Steel, which is wear-resistant and durable to ensure long-term stable operation.

- Global Support & Customization: Support global after-sales service and provide customized solutions for customer needs.

Welcome to contact Gondor Machinery, we will help you get more product information and customized plastic recycling solutions!