Gondor Automatic Poultry Deboning

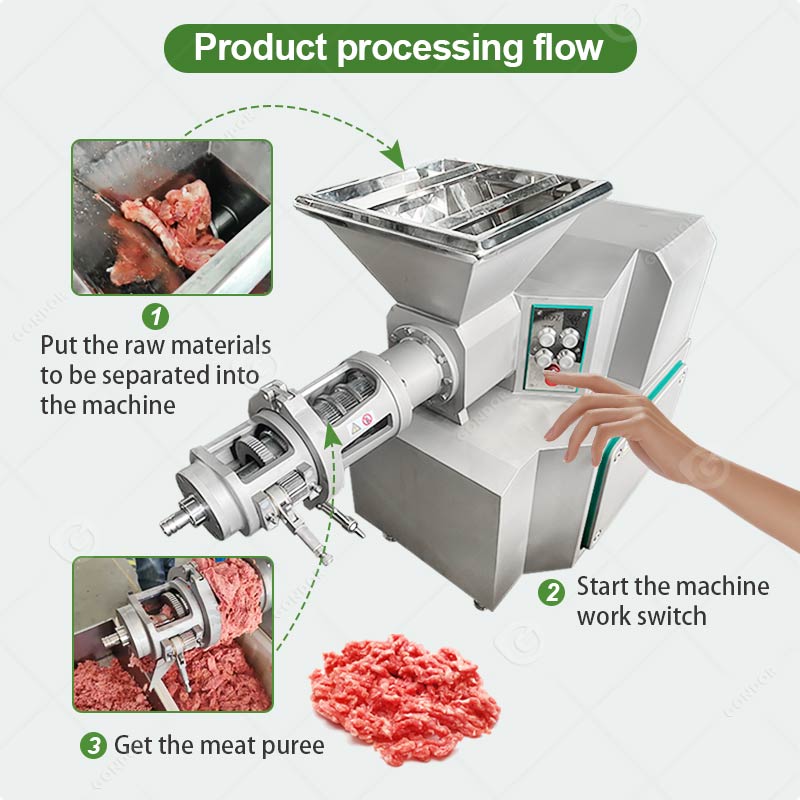

Poultry debone machine is a mechanical device used to separate the bones and meat from meat. It usually consists of a feed port, a separation device, a drive system and a discharge port. In addition, this machine can process meat quickly and in large quantities, saving manpower and time costs. It can also fully extract the essence of meat, reduce waste and improve the utilization rate of meat. Gondor poultry debone machines are widely used in meat processing industry, food manufacturing industry, pet food industry, etc.

Poultry Debone Machine Specification

| Model | GD-BAMSM-H300 | GD-BAMSM-A80 | GD-BAMSM-A130 | GD-BAMSM-A160 | GD-BAMSM-A180 | GD-BAMSM-A220 |

| Voltage | 380v | 380v | 380v | 380v | 380v | 380v |

| Motor power | 7.5kw | 5.5kw | 13/16kw | 22/28kw | 26/32kw | 55kw |

| Yield | 300-500kg/ | 200-300kg/h | 1000-1500kg/h | 2000-3000kg/h | 3500-4500kg/h | 6000-8000kg/h |

| Machine size | 1400*650*

980mm |

1400*650*

900mm |

1990*820*

1300mm |

2130*890*

1400mm |

2420*1200*

1500mm |

2700*1450*

16500mm |

| Weight | 400KG | 400KG | 850KG | 1350KG | 1650KG | 2150KG |

Demand Areas for Meat Deboning Machine

Aquatic Product Processing

In some fish processing, fish meat and fish bones are separated to make fish balls, fish cakes, etc.

Pet Food Production

Provide delicate meat paste raw materials for pet food.

Central Kitchen

Centrally process meat to meet the production needs of standardized dishes.

Poultry Meat Processing

Separation of meat and bones of chicken, duck, goose, etc. to obtain high-quality meat paste for making sausages, meatballs and other products.

Livestock Meat Processing

For example, the meat and bones of pigs and cattle are separated to produce minced meat for making meat patties, canned meat, etc.

Food Ingredient Processing

Provide raw material components after bone and meat separation for the production of other foods.

Biopharmaceuticals

Use it to separate relatively pure bone residues from animal bone raw materials for extracting components such as chondroitin.

Remarkable Functional Characteristics of the Gondor Debone Machine

-

Easy to Use

Button design is usually easy to operate with simple training.

-

Reliable Equipment

Copper core motors make the machine work more stably, durable, and have fewer faults.

-

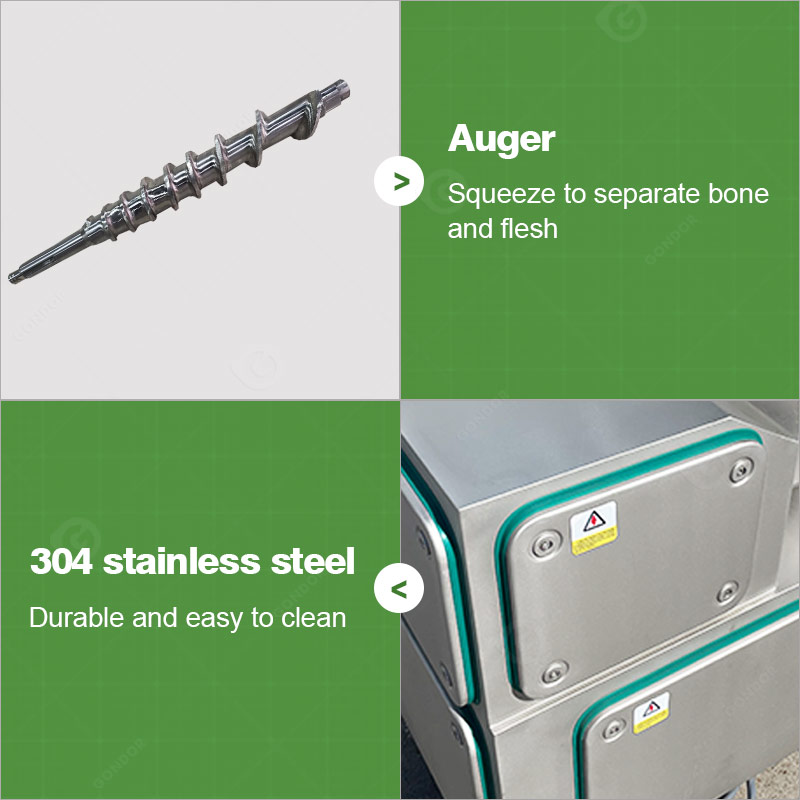

Material Characteristics

The overall design is made of 304 stainless steel, which meets hygiene standards and is easy to clean and maintain.

-

Wide Adaptability to Raw Materials

It has good adaptability to animal skeletons of different sizes and types (poultry, rabbits, small animals, etc.) to a certain extent.

-

High Production Efficiency

Large feed inlet, convenient feeding, fast feeding speed, and greatly improves efficiency compared to manual separation of bones and meat.

-

High Meat Yield

It can make the meat basically free of bone residue, and minimize excessive damage to the meat fiber tissue during processing to ensure the quality of minced meat.

-

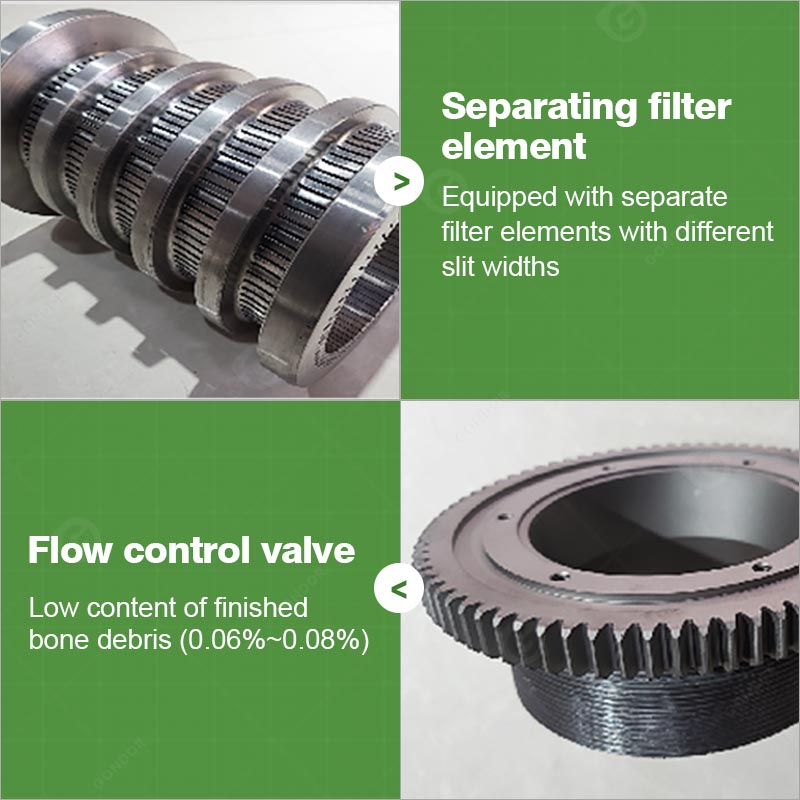

Different Separation Fineness

The machine is equipped with separation filter elements with different slit widths to adapt to different raw materials and better meet customer needs.

Gondor Poultry Debone Machine – A New Benchmark for Efficient Separation

The Gondor poultry debone machine uses advanced technology, with excellent separation effect and clean and thorough separation of meat and bones. Whether it is poultry, livestock or aquatic products, it can easily handle it. Improve product quality and increase output efficiency. Choose the Gondor debone machine to make you stand out in the food processing industry!