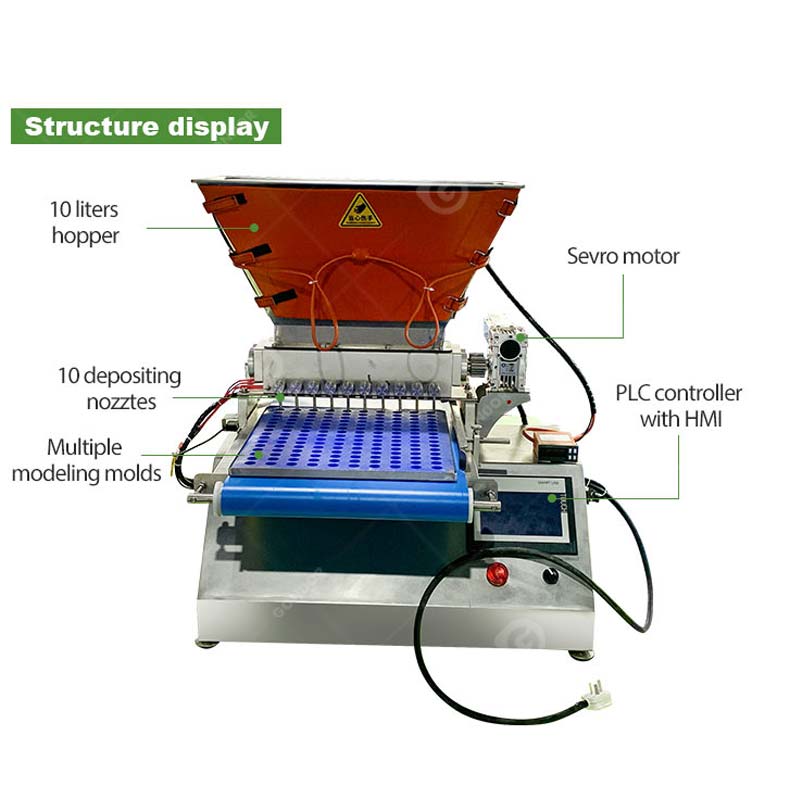

A tabletop candy depositor machine is a compact, ingenious piece of food processing equipment designed for small to medium-scale candy production. It offers many of the functionalities of larger, industrial candy depositors but in a more space-efficient and cost-effective format. This type of candy depositing machine is ideal for artisanal candy makers, small confectionery businesses, and test kitchens. And this powerful table top candy depositor streamlines the candy production process, making it easier than ever to create a wide variety of confections. Gondor machinery is a professional confectionery equipment manufacturer and supplier with high quality tabletop candy depositor machine, and empower business with innovative and reliable solutions. Contact us to buy the candy depositor machines which is tailored to meet our clients’ unique needs.

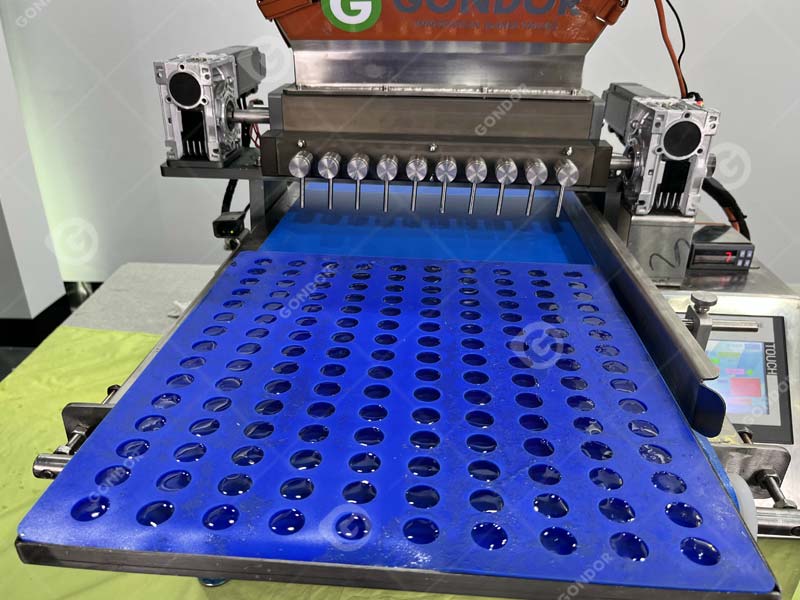

Small Scale Tabletop Candy Depositor Machine in Gondor

Main Functions of Tabletop Candy Depositors

Tabletop candy depositors are specialized food processing machinery which are compact machines designed for the production of small batches of candies with precise control over the deposition process. It is commonly used by small to medium-sized candy manufacturers because of their efficiency, accuracy, and ability to handle various candy types. In addition, this tabletop candy depositor machines play a crucial role in modern confectionery production by providing a versatile, efficient, and cost-effective solution for producing high-quality candies. Here are the main functions of tabletop candy depositors:

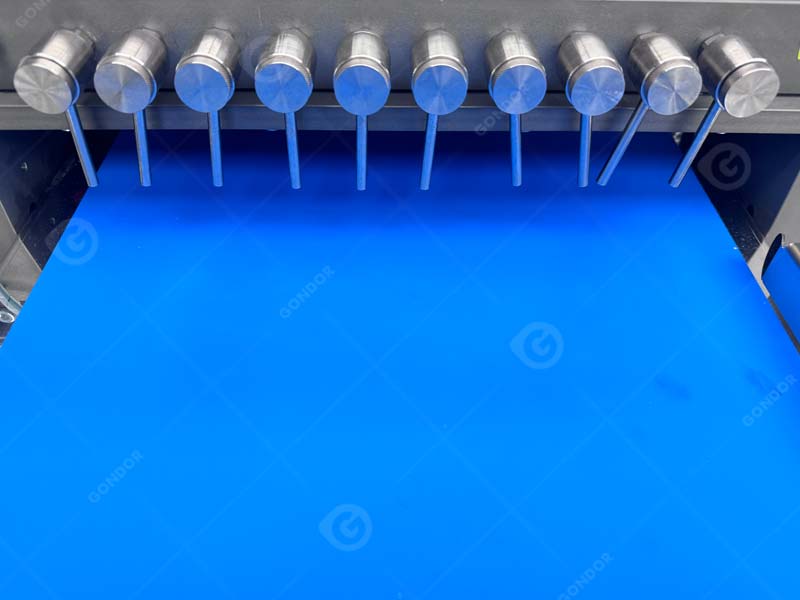

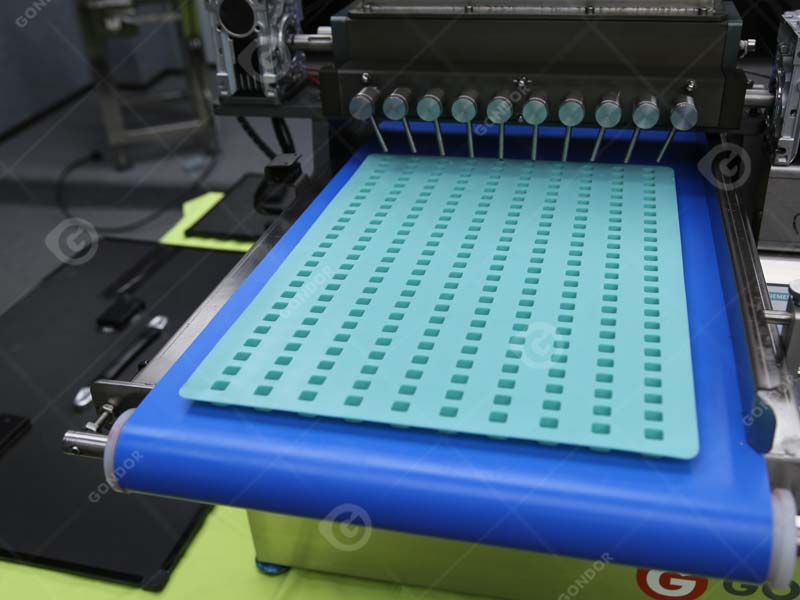

- Precise Dosing: Tabletop candy depositors ensure the accurate and consistent dosing of candy mass into molds, which can help maintain the uniformity in size and the weight across batches.

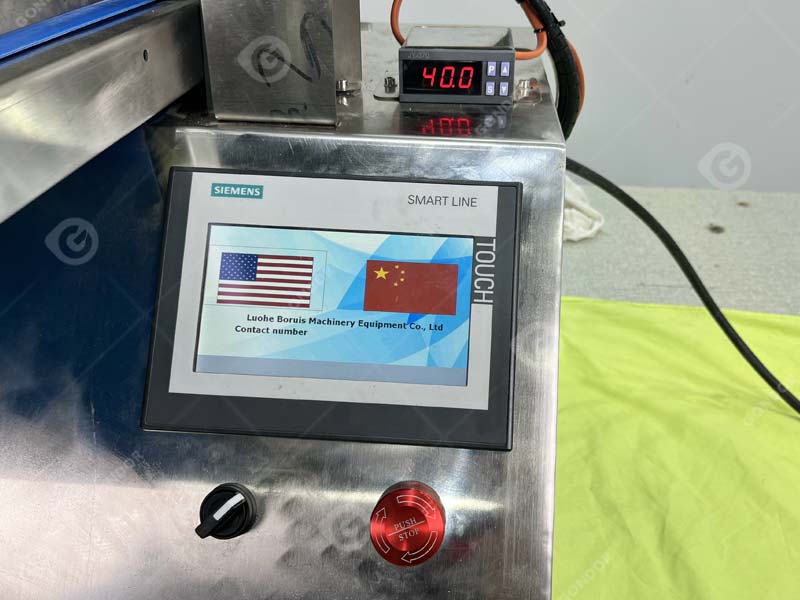

- Controlled Flow: The PLC control system of our Gondor candy depositor machine allows the control over the precise flow of the candy mixture, ensuring that the right amount is deposited every time.

- Multiple Mold Compatibility: These table top candy depositing machines can handle various types of molds, which means the production of a wide range of candy shapes and sizes.

- Quick Changeover: The candy depositors has features of easy mold changeovers, which makes it convenient to switch the candy molds between different candy types and designs.

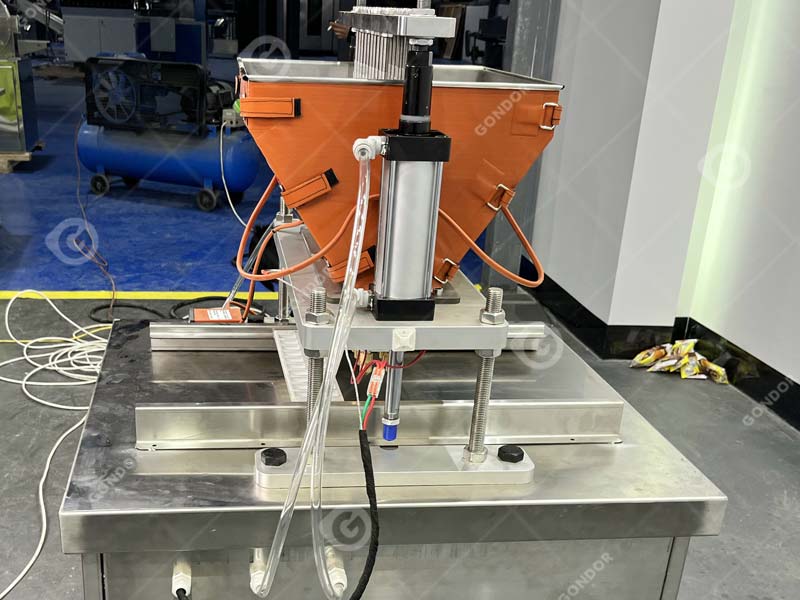

- Heating Elements: our table candy pouring machine has an integrated heating systems, which can maintain the candy mass at the optimal temperature for depositing, preventing crystallization or hardening before molding.

- Cooling Options: Some tabletop candy depositor machine models can offer the cooling options to accelerate the setting of the candy in the process of confectionery production.

- Variable Speed: Operators of our candy depositors can adjust the depositing speed to suit different types of candy mixtures and production requirements, which is suitable for different clients worldwide.

- Adjustable Settings: The deposition parameters are also customized when manufacturing the candy, such as the amount of candy per mold cavity and the interval between deposits.

- Batch Production: It is suitable for small to medium-scale candy production, making them ideal selection for candy producers and R&D environments.

- Reduced Waste: Precise depositing of tabletop depositor machine can reduce the wastage of candy ingredients, which can optimize the resource utilization.

- Wide Range of Ingredients: our candy depositors are capable of handling various types of candy mixtures for candy manufacturer, including chocolate, gummies, caramels, fondants, and more.

- Layered and Filled Candies: Some tabletop candy depositor machines support multi-layer depositing and filling capabilities for creating complex candies to satisfy different clients’ demands.

Applications of Gondor Tabletop Candy Depositor Machine

Tabletop candy depositor machines are versatile candy manufacturing machines which are widely used in various settings to produce a wide range of confectionery products. Gondor group provides this type candy depositing machine to help our clients to improve the production efficiency as well as maintain the high quality candy standards. Here are the primary applications of tabletop candy depositors:

- Gummy Bears and Worms: Candy depositor machines are employed to precisely fill molds for gummies, which can also ensure the consistent size and shape.

- Fruit Jellies: In addition, we also use the candy depositors to handle a variety of jelly mixtures to deposit them accurately into molds for fruit-flavored jellies.

- Molded Chocolates: Tabletop candy depositors are used to deposit chocolate into molds to create shaped chocolate candy, such as bars, hearts, and seasonal figures.

- Filled Chocolates: Besides, table top candy depositing machine are also used for depositing fillings such as caramel, nougat, or fruit pastes into chocolate shells.

- Soft Caramels: Candy depositors can ensure the uniform size and shape of soft caramel pieces for wise investors.

- Chewy Toffees: Moreover, the tabletop candy depositors can be used to deposit toffee mixtures into molds or onto cooling trays to produce toffees.

- Cream Centers: These candy depositor machines can deposit fondant or cream mixtures into molds or as centers for chocolates.

- Fondant Icing: Our candy depositors are used to create uniform fondant shapes for cakes and pastries.

- Vitamin Gummies: Some investors purchase our candy depositor machines to produce gummies that contain vitamins or other nutritional supplements for their business.

- Functional Candies: Besides, they are ideal for creating candies with added functional ingredients to boom their business, such as caffeine or herbal extracts.

- Custom Shapes: In order to attract more consumers, these machines are used to produce novelty candies in custom shapes for holidays and special occasions.

- Color and Flavor Variations: Gondor table candy depositors can deposit different colors and flavors in a single production run for variety packaging.

Advantages of Using Tabletop Candy Depositors

When talking about confectionery manufacturing, the key to produce high quality candy products is precision, efficiency and consistency. Gondor machinery, a leader in the manufacturing of confectionery equipment, has developed a range of tabletop candy depositors that are renowned for their reliability, precision, and versatility. Moreover, our candy depositing machines are integrating advanced technology with user-friendly designs, and provide effective solutions that cater to the diverse needs of the candy-making industry, thus helping businesses optimize their production processes and maintain a competitive edge. Check here for advantages of using Gondor tabletop candy depositor machines:

Precision and Consistency

Gondor tabletop candy depositors can deliver precise and consistent deposits every time, which ensures uniform candy size and weight to guarantee the quality control and customer satisfaction.

Versatility

Our candy depositor machines can handle a wide variety of candy types, including gummies, hard candies, chocolates, and more, which will accommdate diverse production lines and creative designs.

Ease of Use

Equipped with user-friendly interfaces and straightforward controls, the machines are easy to operate, which will reduce the need for extensive training and allows operators to focus on production.

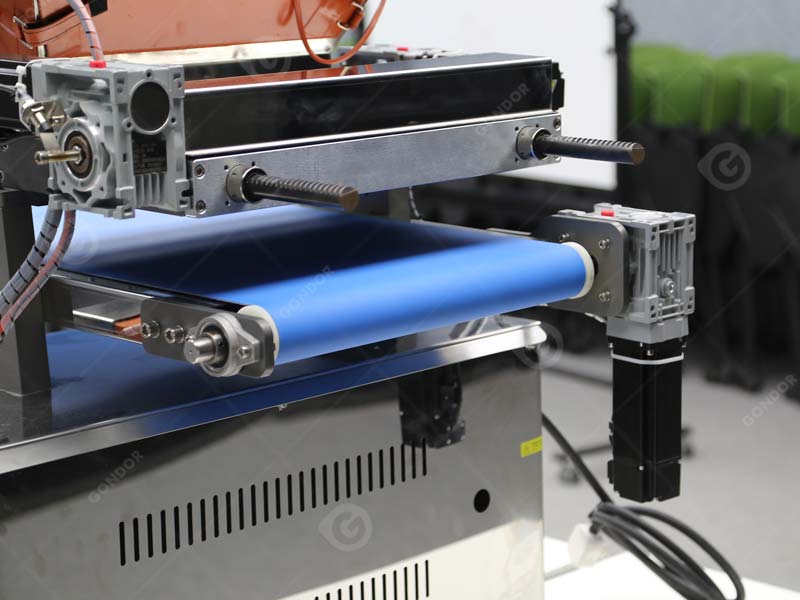

Compact Design

The tabletop design candy depositor is ideal for businesses with limited space. What’s more, the candy depositing machines are robust and capable of handling significant production demands.

Increased Production Efficiency

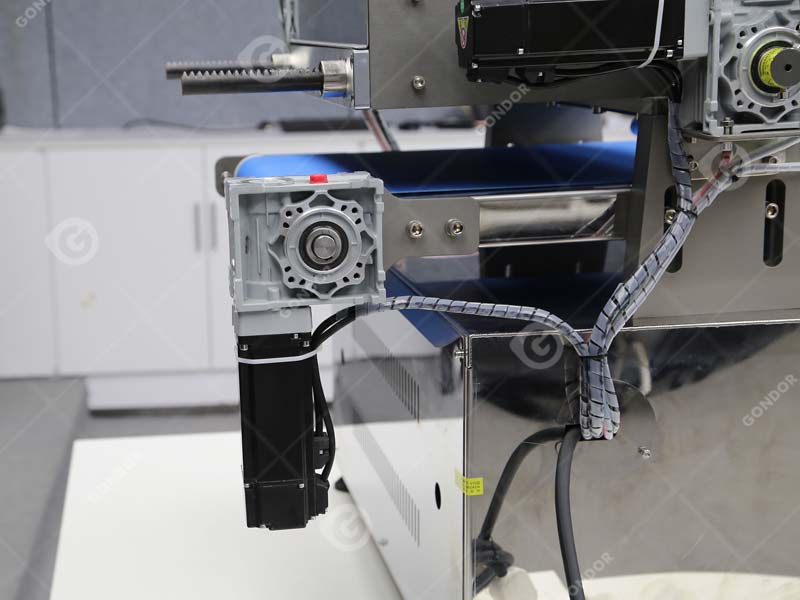

With the automatic system in depositing process, the machines can reduce manual labor and increase production speed and efficiency, which will lead to higher output and reduce operational costs.

Customization Options

Gondor can tailor the candy depositors to their specific needs, which includes adjustable deposit sizes, customizable molds, and more. And this personalized production can maximize the profits.

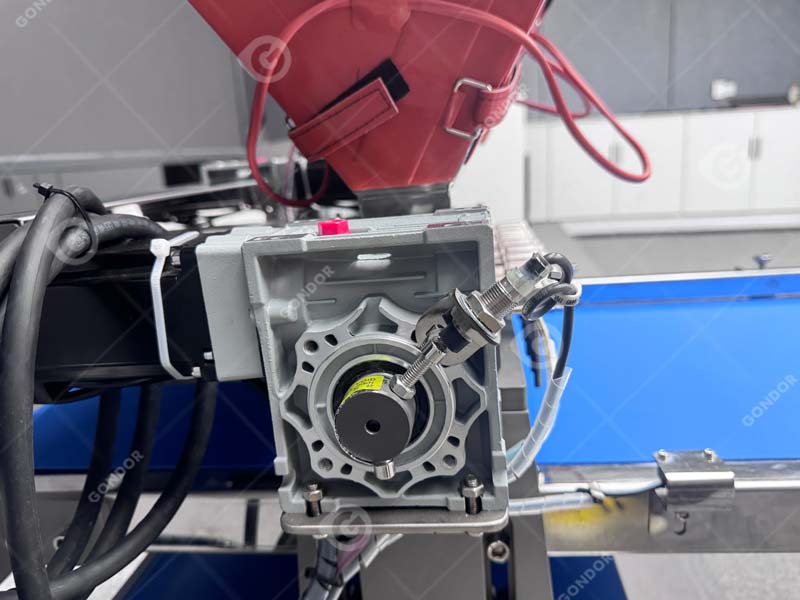

Quality & Durable Materials

Constructed from high-quality food-grade materials, our tabletop candy depositors are built to last and offer excellent durability, which can withstand the rigors of continuous production.

Cost-Effectiveness

It can be operated smoothly, and is easy to maintain and clean. So, wise investors can achieve a higher return on investment in a tabletop candy depositor by reducing labor costs, waste, and errors.

Support and Service

Gondor machinery offers excellent customer support and service to maximize the benefits of our clients, which includes the comprehensive training, troubleshooting, and maintenance services.

Distinctive Qualities and Benefits Desktop Candy Depositor Machines

By choosing Gondor Machinery to purchase the tabletop candy depositors, businesses can enhance their production capabilities, improve the product quality, and maintain a competitive edge in the confectionery industry. Moreover, we are always commitment to innovation and customer satisfaction and this makes us a trusted partner for candy manufacturers worldwide. And they will never regret to choose Gondor to buy candy depositors, Here are some innovative features and unique selling points for your reference when buying food processing machinery online:

Precautions for Operating Tabletop Candy Depositor Machine

It is vital to maintain candy quality and ensure the safety of operators to operate a tabletop candy depositor machine safely and efficiently. Whether you’re using the candy depositor machine in a commercial candy manufacturing setup or a small confectionery business, following these precautions below can help you avoid common issues and maximize productivity. Here are the essential safety and operational precautions for using a candy depositor machine:

- When connecting to a power source, operators had better ensure that the voltage matches the specifications and the wiring is correct. In addition, the device casing must be connected to a reliable a reliable protective ground wire.

- Before turning on the candy depositing machine, check whether all screws are tightened properly.

- During operation, if there is any abnormal noise, stop the machine immediately and check for issues. Be attention, remember to disconnect the power before inspection. It is prohibited to troubleshoot while the machine is running.

- Do not touch the heating parts directly with your hands while the machine is in operation.

- When cleaning the candy depositor machine, pour in hot water and let the machine run repeatedly. Then open the valve to allow any remaining syrup to flow out.

- The machine should not be modified at will. If modifications are necessary, consult us to determine feasibility.

Contact Gondor – Top Tabletop Candy Depositor Machine Manufacturer

Contact Gondor here to experience how our advanced tabletop candy depositor machines can elevate your production line. As a leading manufacturer in the confectionery industry, we never stop to improve efficiency, enhance product quality, and expand your product range. At Gondor machinery, there are various food processing and packaging machinery to satisfy different requirements of our clients, including the vertical candy depositors and tabletop candy depositing machines. Besides, our expert team is here to assist you every step and can help drive your success in the competitive candy market. Feel free to contact us to start your project and maximize the profits of your investment!