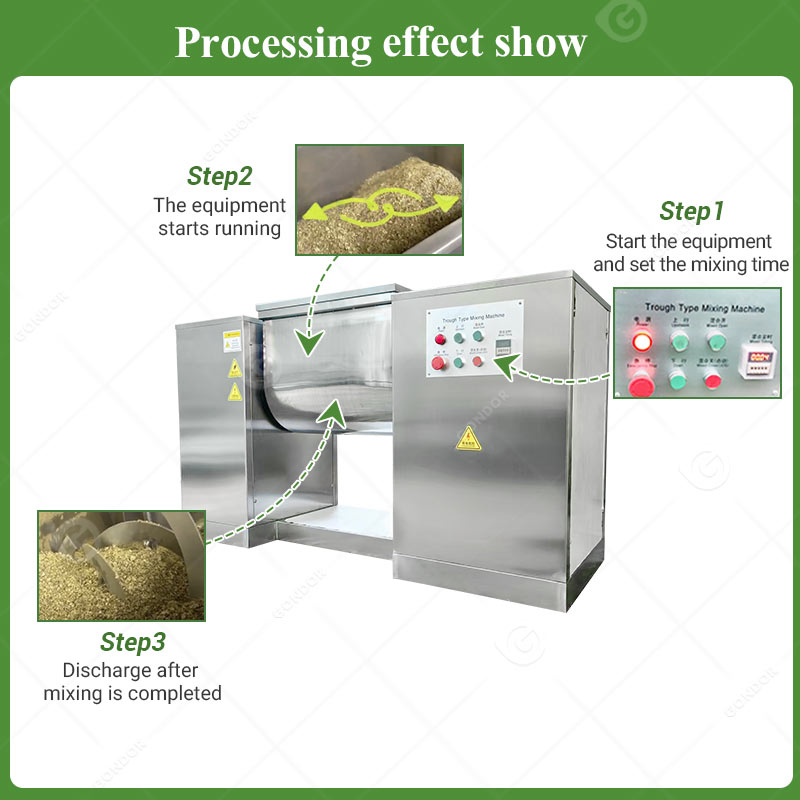

A trough mixer is an efficient mixing equipment for powdery materials, which is widely used in food, chemical industry, medicine, feed and other industries. The S-type stirring paddle is driven by mechanical transmission, and the gap between the paddle and the tank body is small, there is no dead angle in mixing, so all kinds of main and auxiliary materials can be stirred accurately and evenly. The equipment supports mixing time setting, automatic shutdown and electric dumping, which is convenient to operate, high in efficiency, and low in energy consumption and has become an ideal choice for many production lines.

|

Model |

Mixing motor (kw) | Discharging

motor (kw) |

Weight(kg) | Mixing

speed(r/min) |

Size(mm) |

| 50L | 1.5 | 0.37 | 200 | 24 | 1370*500*850 |

|

100L |

2.2 | 0.55 | 250 | 24 | 1600*550*950 |

| 200L | 4 | 0.75 | 380 | 24 | 1900*600*1050 |

|

400L |

5.5 | 1.1 | 680 | 24 | 2350*750*1300 |

| 600L | 7.5 | 1.5 | 900 | 24 | 2600*900*1450 |

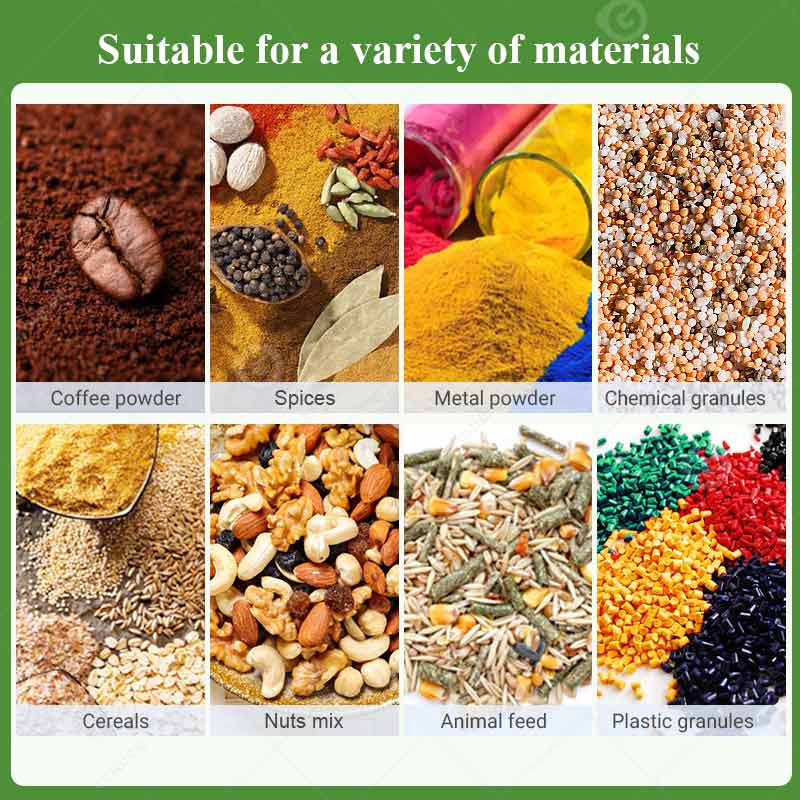

A Wide Range of Applications of U Trough Mixer

U trough mixer, with its excellent adaptability and customizable design, is suitable for almost all fields that need dry powder or particle mixing:

Trough Mixer can be easily competent for coarse particles, fine powders, fibrous and flaky materials, ensuring high uniformity of mixing.

Horizontal Trough Mixer’s Outstanding Equipment Advantages

Support Customization and Flexibly Match the Demand of the Production Line

Trough mixers can be customized with different capacities according to customers’ needs to meet various production scales. To achieve efficient production, it is recommended to use:

- Industrial Powder Grinder Machine: Suitable for crushing various dry materials, with adjustable fineness and simple operation, and suitable for material pretreatment before mixing.

- Vertical Form Fill Seal Machine: Automatic weighing, sub-packaging, sealing, improving packaging efficiency, suitable for all kinds of powder products.

With crushing and packaging equipment, we will build an efficient mixed production line to help enterprises improve their quality and productivity. Welcome to consult the customized plan!