Gondor Vacuum Freeze Drying Equipment

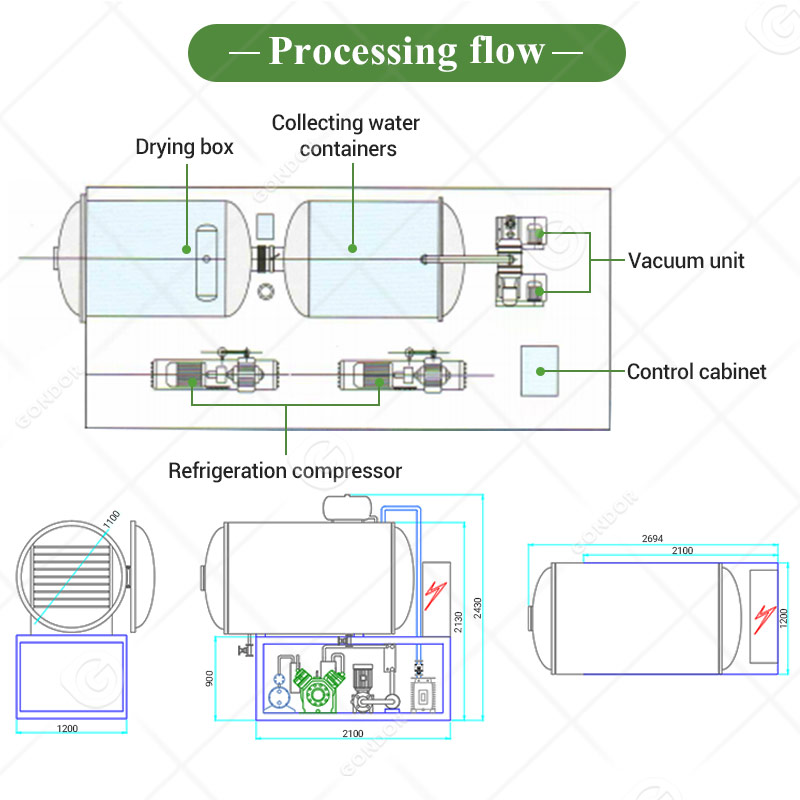

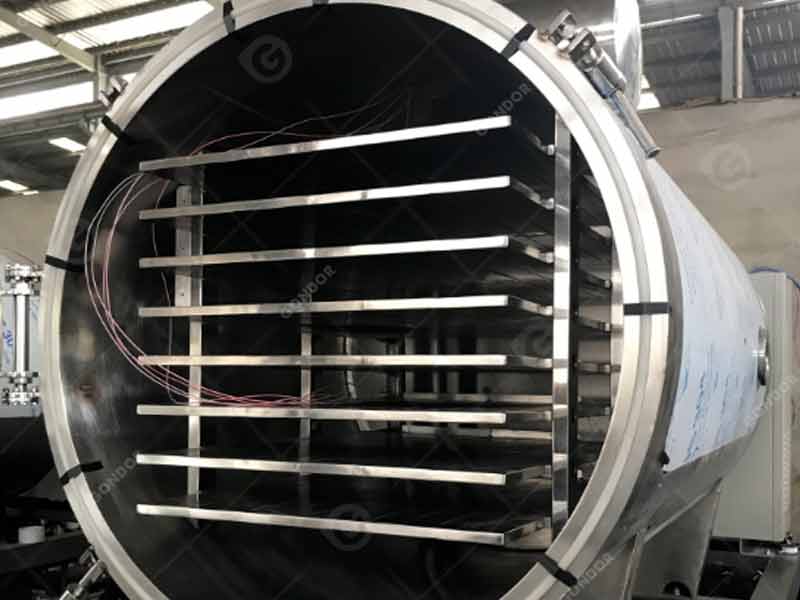

A vacuum freeze drying machine is an advanced equipment for dehydration under a vacuum condition. The drying process is completed by freezing the material at ultra-low temperatures and then subliming the water in the material directly from ice state to water vapor in low-pressure environment. This technology can retain the nutrition, color, flavor, and shape of the product to the maximum extent, and it is one of the most recognized high-end dehydration solutions at present.

Compared with the traditional hot air drying method, freeze-drying hardly destroys the molecular structure of materials and does not produce high-temperature oxidation or nutrient loss. It is a true “green drying” technology, which is widely applicable to the deep processing needs of many industries around the world.

Vacuum Freeze Drying Machine Specification

|

Model |

GD–LVFD-1 | GD–LVFD-5 | GD–LVFD-10 | GD–LVFD–15 | GD—LVFD-20 |

| Drying Box Dimension

(¢×L)(m) |

Ø0.7*0.7 | Ø1.1*1.2 | Ø1.2*1.5 | Ø1.14*1.8 |

Ø1.5*1.9 |

|

Effective Drying Plank Area(㎡) |

1.1 | 5 | 10 | 15 | 20 |

| Drying Plank Working Temperature(℃) |

-50~+60 |

||||

|

Drying Plank’s Different In Temperature(℃) |

±1 | ||||

| Condenser Temperature(℃) |

-65±5 |

||||

|

Condenser Water -catching Weight(Kg) |

16 | 28 | 60 | 80 | 85 |

| Equipment footprint and height(M2*M) | 2*2.2 | 20*2.5 | 20*2.5 | 30*2.5 |

35*2.5 |

|

Method Of Defrosting |

Spraying and Inundating | ||||

| Working Condition |

Temperature 5℃~30℃ Relative Humidity<75% |

||||

|

Power(kw) |

16 | 18 | 25 | 28 | 60 |

| Setting Dimension(㎡×h) | 2*2.2m | 5*2.3m | 10*2.3m | 20*2.5m |

20*2.5m |

Applicable Fields of Vacuum Freeze Dryer

Vacuum freeze dryer, with their high efficiency and low-temperature sublimation drying technology, is widely used in many high value-added industries to help improve product quality and value re-engineering.

Application Scenarios of Vacuum Freezing Drying Machines

Core Functional Advantages of Vacuum Drying Machine

The equipment has high control precision, which ensures that the materials are dried under precise parameters and avoids composition fluctuation.

The structure design is compact and reasonable, and the multi-layer structure improves the material placement density and production efficiency.

Low energy consumption, high efficiency, greatly improved production capacity, reduced operating costs, and quick return.

Freeze-drying can retain the nutritional structure to the maximum extent, which is an ideal choice for organic and healthy food production.

Freeze-dried products almost recovered their original taste and texture after rehydration.

It dries thoroughly, has low moisture content, reduces bacterial growth, and can be stored at room temperature.

Global Market Outlook

With the increasing demand of global consumers for organic healthy food, high-end drugs, and natural skin care products, the market demand for vacuum freeze drying machine is increasing exponentially, and it has become the first choice equipment for many international enterprises. If you are interested in a vacuum freeze dryer, we can also provide the following related equipment for your reference:

- Heat Pump Drying Oven: Low-temperature energy-saving drying, suitable for dehydration of heat-sensitive agricultural products.

- Mesh Belt Dryer: Continuous operation, suitable for uniform drying of large quantities of materials.

- Vegetable Wash Machine: Using the principle of bubble tumbling, it can quickly and efficiently remove impurities and residues on the surface of fruits and vegetables.

Please feel free to contact us for detailed parameters, quotations, or customized solutions. We look forward to working with global partners to promote the development of food innovation technology!