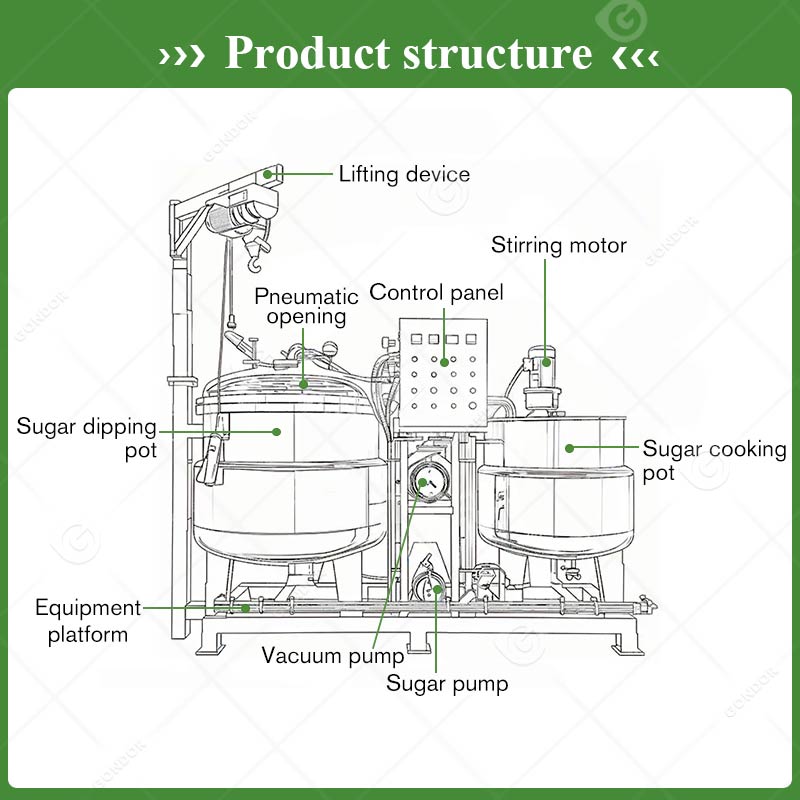

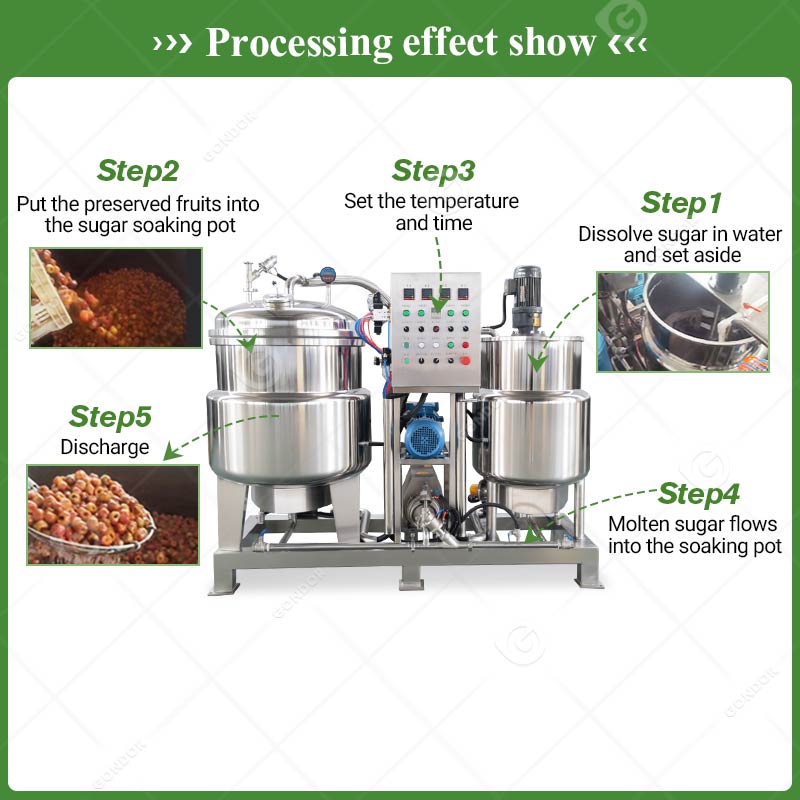

The vacuum sugar soaking machine is an efficient equipment specially designed for the production of preserved fruits, sugar-coated nuts, and sweet baking materials. It can significantly improve the sugar penetration efficiency by vacuum pressure technology, and the speed can reach three times that of traditional methods, thus greatly shortening the production cycle. At the same time, this technology can better retain the natural color, flavor, and nutritional components of raw materials. The whole equipment is made of food-grade 304/316L stainless steel, which conforms to international hygiene standards. It is equipped with an intelligent PLC touch-screen control system, which can accurately adjust the vacuum degree, temperature, and pressure, and realize the whole automatic operation. With its high efficiency, wide applicability, and solid structure, this equipment has become an indispensable piece of equipment in the modern candy and preserves manufacturing industry.

| Model | capacity | Voltage | Power

(Sugar Pot/Sugar Pot/Vacuum Pump) |

Pot diameter * depth * thickness(mm) | Dimensions(mm) | Weight | Mode of heating |

| 100L | 50kg | 380V

50HZ |

18/18/2.35KW | 500*450*3 | 2000*720*1350 | 350kg | Electric heating/

steam heating |

| 200L | 100kg | 24/24/2.35KW | 700*500*4 | 2200*1000*1450 | 400kg | ||

| 300L | 150kg | 24/24/4KW | 800*600*4 | 2450*1350*1550 | 500kg | ||

| 400L | 200kg | 24/24/4KW | 800*800*4 | 2450*1350*1750 | 700kg | ||

| 500L | 250kg | 24/24/4KW | 1000*630*4 | 2500*1430*1900 | 700kg | ||

| 800L | 400kg | 36/36/5.5KW | 1000*1000**4 | 2500*1430*2460 | 850kg | ||

| 1000L | 500kg | 48/48/5.5KW | 1200*890*5 | 2600*1650*2230 | 1100kg |

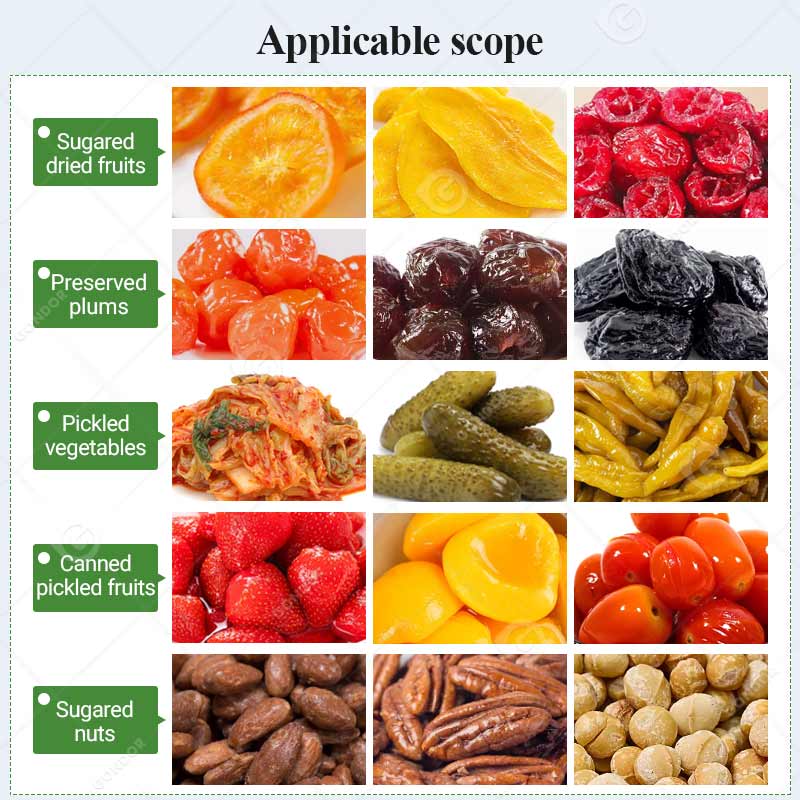

Application Industries of the Vacuum Sugar Soaking Machine

The vacuum sugar soaking machine is widely used across different sectors of the food industry:

- Food Processing Plants – Large-scale candied fruit and preserved food production.

- Candy Manufacturers – Sugar coating and candy syrup impregnation.

- Fruit Preserve Producers – Processing dried fruits, sugared fruits, and jams.

- Nut Processing Plants – Sugar-coated peanuts, almonds, cashews, and other confectionery nuts.

- Bakery Ingredient Suppliers – Preparation of sweetened bakery raw materials.

- Pickling Facilities – Used for pickling vegetables such as cucumbers and other fermented products.

Working Advantages of Fruit Vacuum Impregnation Machine

Related Machines You May Be Interested In

To meet the full-process production needs of diverse clients, we also offer the following services:

- Vacuum Fryer: Healthy, low-oil fruit and vegetable crisps.

- Double Jacketed Steam Kettle: Processing of jams, sauces, and candy bases.

- Sugar-Making Kettles: Specialized for preparing sugar syrups.

- Cooling Systems: Rapid temperature reduction to preserve product texture and flavor.