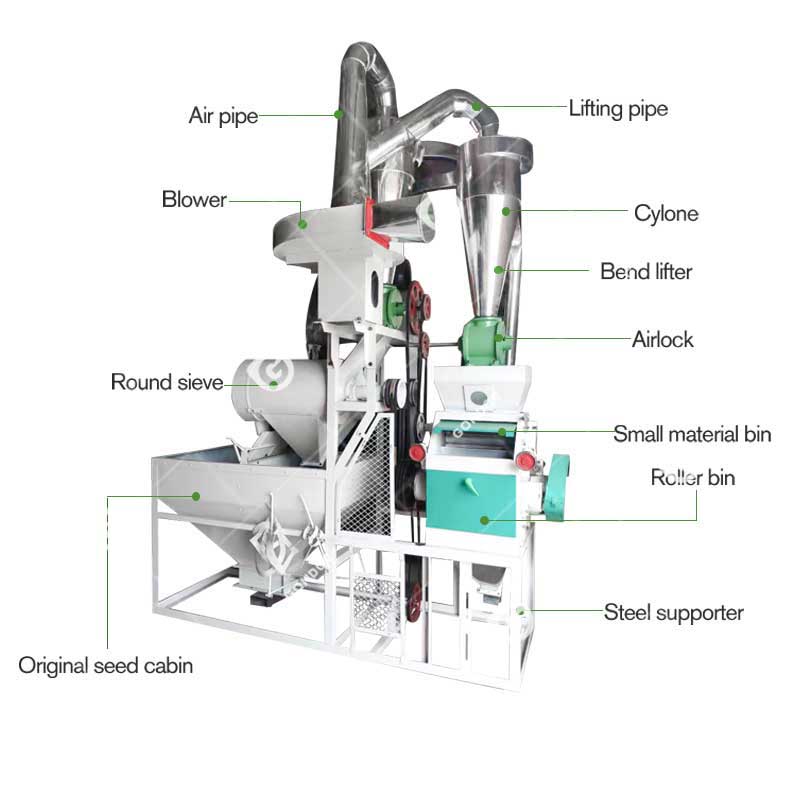

Wheat corn flour milling machine is a type of equipment that can be utilized in small flour mills by individuals and families for processing wheat or corn. It can also be employed in food factories to handle other grains such as cocoa beans, soybeans, oats, etc. Typically, it comprises a feeding system, a grinding system, a screening system, a transmission system, and a control system. It features high efficiency, stable performance, no dust overflow, low energy consumption, and easy maintenance. Moreover, Gondor’s mill is capable of producing ultra-fine flour ranging from 40 to 120 mesh. It is extensively applied in flour mills, food processing plants, and other similar locations.

| Model | Output (kg/h) | Weight (kg) | Dimension(mm) | Power(kw) |

| 6F2235 | 200~350 | 800 | 2200*900*3150 | 7.5+3 |

| 6F2240 | 300~450 | 900 | 2250*1000*3150 | 11+3 |

| 6F2250 | 400~550 | 1000 | 2350*1000*3150 | 15+4 |

Demand Areas for Flour Milling Machine

Flour Production Companies

They are the main demand side, producing various grades of flour for making bread, noodles, cakes and other foods.

Food Processing Plants

Such as noodle processing plants, dumpling wrapper production plants, etc., require flour of specific quality to process products.

Baking Companies

There is a large demand for different types of flour, which are used to make baked foods with different tastes and characteristics.

Feed Industry

Processing grains and other raw materials into feed powder suitable for different animals. Some feeds need to be finely crushed to facilitate animal digestion and absorption.

Liquor Brewery

Some raw materials such as sorghum and wheat need to be crushed and fermented before brewing processes.

Chemical Industry

Use flour mills to crush specific raw materials for the production of raw materials or additives for chemical products.

Pharmaceutical Industry

Crushing some medicinal materials to meet the requirements of raw material particle size for different dosage forms in the production process of drugs.

Scientific Research Field

Agricultural research institutions: used to study the composition and structure of grain crops, which requires grinding grain into powder for analysis and testing.

Food Research Units

In the process of developing new food formulas, it is necessary to grind raw materials for testing.

Some Large-Scale Comprehensive Processing Bases

Processing a variety of crops, flour mill is one of the processing equipment.

Excellent Advantages of Gondor Wheat Milling Machine

-

High Production Capacity

It can process a large amount of grain raw materials per unit time to meet the needs of large-scale production.

-

Continuous Operation

It has the ability to operate stably for a long time, without frequent shutdown and rest, which greatly improves production efficiency.

-

High Degree of Automation

Reduce manual intervention, automatically complete a series of processes such as feeding, grinding, screening and discharging, saving time and manpower.

-

Precision Grinding

The fineness of grinding can be adjusted according to needs, and the consistency of each batch of products can be guaranteed.

-

Easy Installation

All interfaces are connected by flanges, with small footprint and simple operation.

-

Reasonable Structure

Stable operation, reliable performance, low noise, no dust, safe and hygienic, energy-saving and environmentally friendly.

Gondor Wheat Corn Flour Milling Machine – Opening a New Era of Efficient

Our wheat corn flour milling machine is your best choice to improve flour production efficiency! It has a strong grinding capacity and can quickly process large amounts of grains, saving you time and cost. In addition, the finished products produced by this equipment have the characteristics of fine flour, high gluten content, few impurities, and high nutritional value. Choosing Gondor means choosing efficiency, quality and trust. Order now, let us create a better future together!