Gondor-skuins skroefvervoerband-poeieroordragstelsel

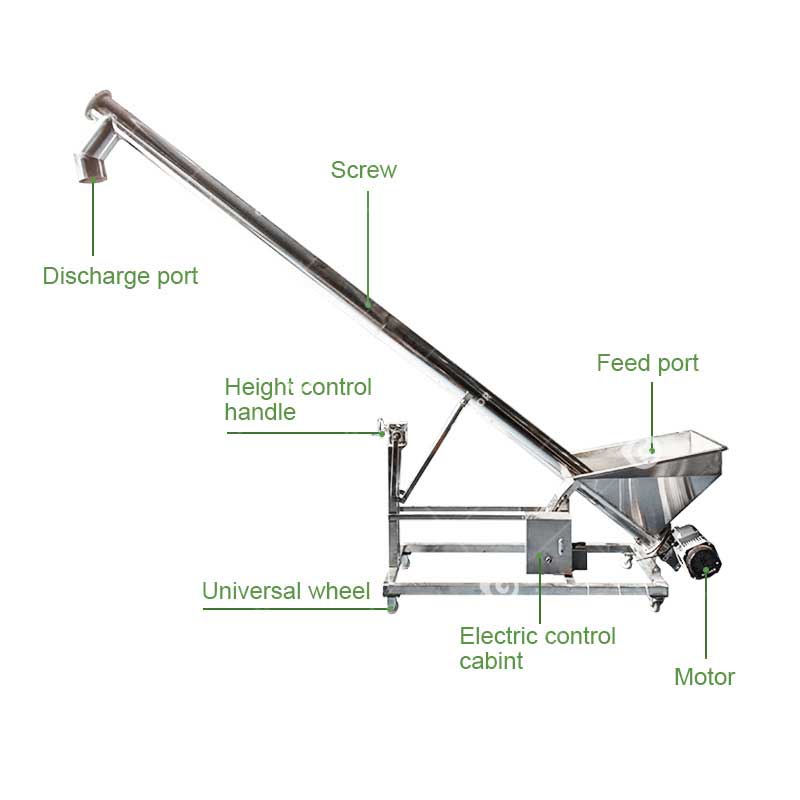

Skuins poeierskroef hysbak vervoerband is hoofsaaklik saamgestel uit spiraal lemme, intelligente beheer elektriese boks, suiwer koperkernmotor, hoogte verstel handvatsel, voerpoort, en afvoerpoort. Wanneer jy werk, die aandryftoestel dryf die spiraallemme om te draai, en die materiaal beweeg op of af langs die binnekant van die omhulsel onder die druk van die spiraallemme, daardeur die materiële vervoer te realiseer. Buitendien, die materiaal kan geroer word, gemeng, verhit, en afgekoel tydens die vervoerproses. Die materiaalvloeitempo kan ook deur die laai- en aflaaihek aangepas word.

Hellende poeierskroef hysbak vervoerband spesifikasie

| Model | GD-MSC-A | GD-MSC-B |

| Spanning | 220V/380V | 220V/380V |

| Krag | 1.1-3kw | 1.1-3kw |

| Hoogte | Aanpasbaar | Verstelbaar |

| Deursnee | 102mm;114mm;141mm;219mm of aanpasbaar | |

| Lengte | 1-4m, aanpasbaar | |

| Beheerkas | / | Toegerus |

Toepaslike nywerhede van Gondor-skuinsskroefvervoerband

Belangrikste kenmerke van Gondor-skroefhysbakvervoerband

Doeltreffende vervoer

Dit kan materiaal vinnig van lae na hoë plekke oplig en produksiedoeltreffendheid verbeter.

Kompakte struktuur

Hierdie masjien neem relatief min spasie op en is maklik om te installeer en in verskillende scenario's te gebruik.

Stabiele werking

Verseker gladde materiaalvervoer met minder wanfunksies en skommelinge.

Sterk aanpasbaarheid

Dit is geskik vir die vervoer van 'n verskeidenheid poeieragtige, korrelvormig, en klein blokmateriaal.

Goeie verseëling

Voorkom materiaallekkasie en stof effektief, en hou die werksomgewing skoon.

Duursaam en betroubaar

Gemaak van hoë kwaliteit materiale en gevorderde tegnologie, dit het 'n lang dienslewe.

Energiebesparing

Dit kan effektief energie bespaar en bedryfskoste verminder tydens operasie.

Aanpasbaar

Aangepas volgens kliënte’ spesifieke behoeftes en werkscenario's om aan verskillende produksievereistes te voldoen.

Multifunksionele skuins poeierskroef-hysbakvervoerband – Gondor se kragtige produk

Gondor-skuins poeierskroef hysbak vervoerband, jou doeltreffende oordragdeskundige! Of dit nou poeier is, korrelvormig, of klein blokmateriaal, dit kan die oordrataak uitstekend voltooi. Goeie verseëling voorkom materiaallekkasie en stof, wat omgewingsvriendelik en skoon is. Daarby, die Gondor-skroefvervoerband is duursaam en energiebesparend, jou langtermyn bedryfskoste te verminder. Die keuse van die Gondor multifunksionele poeierskroefhysbak beteken om doeltreffend te kies, stabiel, en gerieflik, wat jou produksie meer krag sal gee en jou besigheid sal floreer!

Bedryfsbeginsel van 'n skuins skroefvervoerband

Die werkbeginsel van 'n skuins skroefvervoerband vir poeier is gebaseer op die rotasie van heliese lemme wat die materiaal in 'n skuins rigting aandryf: