Welcome to our FAQ page! Here, we will answer common questions about two devices, candy filling machine and candy counting machine. These machines are designed for candy manufacturers to help them achieve accurate counting and filling, thereby improving production efficiency. Read on to learn about the functions of these important devices and the many benefits they can bring to your business.

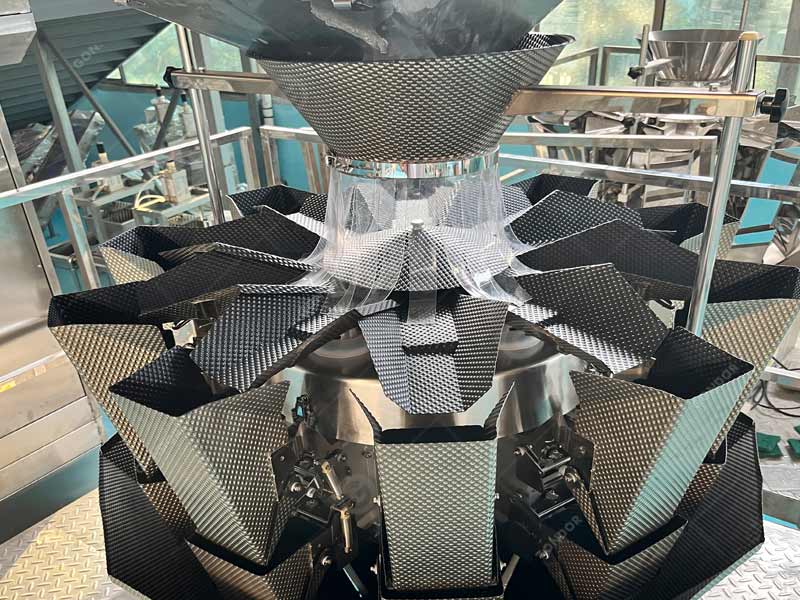

Gondor Candy Counting Machine

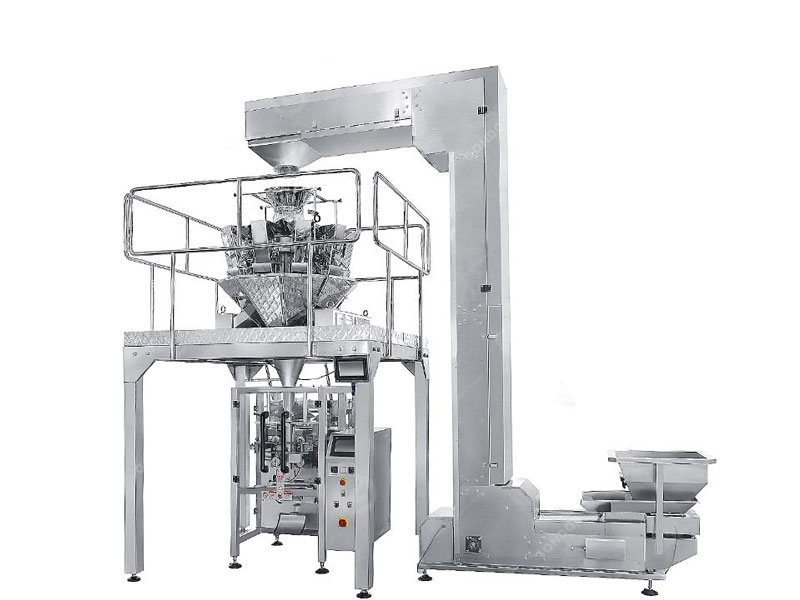

Gondor Vertical Packaging Machine

What Is a Candy Counting Machine?

A candy counting machine is a device used to automatically count small candies such as hard candies, chocolates, and soft candies. This device is extremely important for companies that want to package candies in precise quantities. Candy counting machines use advanced sensors to ensure that the number of candies in each package is accurate, thereby reducing manual labor and human errors.

Advantages

- High Accuracy: Ensures accurate counting of candies.

- High Efficiency: Increases production speed by automating the counting process.

- High Adaptability: Suitable for various types and sizes of candies.

How Does a Candy Filling Machine Work?

Candy filling machines are designed to measure and fill specific quantities of candy into packages. This machine is particularly useful for high-volume production and guarantees accurate filling. Often, vertical form fill seal machines are used in conjunction with counting machines, making the packaging process more efficient and error-free.

- Measuring Mechanism: The machine accurately measures the weight or number of candies.

- Filling Process: Once the required quantity is reached, the candies are automatically dispensed into containers or bags.

- Consistency: Each package contains the same amount of product.

- Cost savings: Reduce material waste and avoid human errors.

- Food safety: Ensure hygienic filling process and prevent contamination.

Which Industries Use Gummy Counting Machines?

These machines are not only widely used in candy production, but also in the following industries:

Are These Machines Easy to Clean and Maintain?

Yes, our candy and gummy counting machines are designed for easy cleaning and meet the sanitation standards of the food and confectionery industry.

- Quick Disassembly: Most machines can be disassembled quickly for easy and thorough cleaning.

- Durable Materials: Made of food-grade materials such as stainless steel, they can withstand frequent cleaning.

- User-Friendly Interface: Easy operation, staff can master maintenance and operation methods without special training.

Can These Machines Handle Different Types of Candies and Gummies?

Of course they can! Our candy counting and filling machines are highly adaptable and suitable for many types of candies, including hard candies, gummies, chocolates, and even some small non-food items such as capsules.

The machines can be adjusted for candies of different weights, sizes, and shapes.

The machine’s speed, filling volume, and counting sensitivity can be adjusted according to the type of candy or gummies.

Other Related Products Recommended by Gondor Machinery

If you are looking for more equipment to improve the efficiency of your production line, we also offer a range of efficient automation equipment for the food, pharmaceutical and nutritional products industries. These machines can help you optimize your production process, thereby increasing productivity and ensuring consistent product quality.

Designed for viscous liquids and paste products, suitable for filling paste substances such as jam, honey, cream, gel, etc., with precise filling control and no dripping function to ensure consistent product quantity in each package.

Designed specifically for powdered products, it can accurately fill various types of powders, such as milk powder, protein powder and medicinal powder. Its precise measurement and filling functions help ensure that the amount of powder in each package is consistent.

Multihead weigher can accurately weigh a variety of granular or small block products, such as candy, nuts and snacks. This equipment excels in improving packaging speed and accuracy and is widely used in the food packaging industry.

Gondor Paste Filling Machine

Gondor Powder Filling Machine

Gondor Multihead Weigher

This article explains the functions and advantages of candy counting machine and candy filling machine in detail to help food manufacturers improve packaging accuracy and efficiency. We also recommend related equipment and provide comprehensive automated production solutions. Welcome to contact our sales team to learn how to customize it according to your production needs.