Recently, Gondor received an inquiry from a customer from Ghana. The customer mainly engages in yogurt business. With the expansion of business scale, it plans to introduce advanced equipment to improve production efficiency. After learning about Gondor milk pasteurizer machine on Instagram, he consulted with us through the official website and had in-depth communication with us. After many exchanges and inspections, the customer showed high recognition of our equipment and services, and asked his friend to sign the purchase contract on the spot.

Customer Background: Transformation from Manual to Large-Scale Production

This Ghanaian customer mainly produces and sells yogurt, but due to the low efficiency of manual production, it is difficult to meet market demand. After learning about the Gondor milk pasteurizer machine through Instagram, he was attracted by its efficient and professional design and sent an inquiry through the official website.

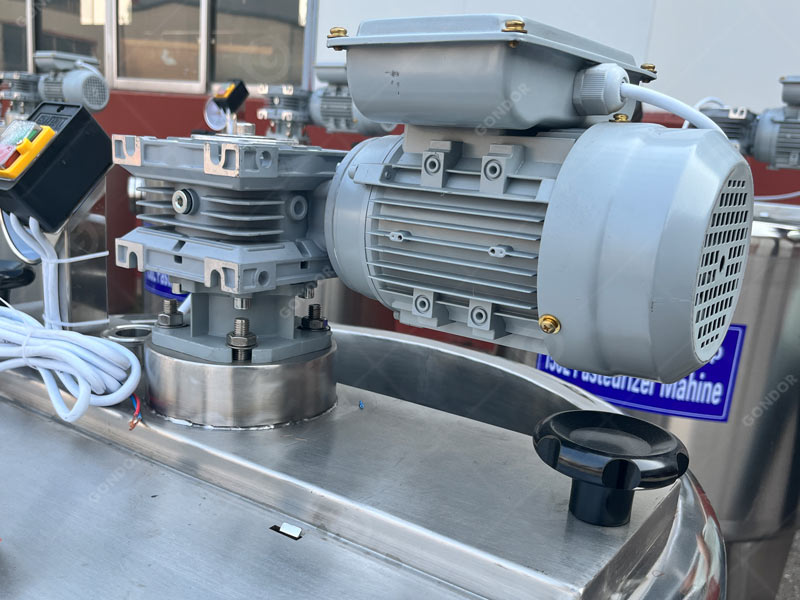

During the communication process, the customer said that he knew little about the machine’s details. After deeply understanding the customer’s needs, the Gondor business team recommended a variety of models and configurations of batch pasteurizers and focused on the unique advantages of high-configuration equipment, including:

Effectively reduces the particle size of the material, making the yogurt taste more delicate and extending the shelf life.

Uniform heating, maximizing the retention of product nutrients, and reducing heat energy waste.

This professional suggestion was highly recognized by the customer and also allowed the customer to see the possibility of future brand upgrades.

Customer Factory Inspection: Trust Is Built Through Communication and Witnessing

In mid-to-late December, to ensure the reliability of cooperation and the quality of equipment, the Ghanaian customer specially invited his friend in China to go to the Gondor factory for an on-site inspection on his behalf. It is understood that this friend is also a professional factory inspector who has strict evaluation standards for production processes and equipment quality. During the factory inspection, the customer’s friend conducted an in-depth inspection of the factory and was deeply impressed by Gondor’s equipment and factory management through detailed communication and on-site testing. The following are the aspects that the customer focused on during the factory inspection:

After the factory inspection, the customer’s friends showed great confidence in the quality and service of Gondor’s equipment. Especially in the technical details of the batch milk pasteurizer and paste filling machine, the customer was not only satisfied but also took the initiative to ask about the functions and uses of other equipment. With efficient communication between the two parties, the cooperation was quickly reached, and the purchase contract was signed on the day of the factory inspection, further consolidating the trust and cooperation foundation between the two parties.

Subsequent Plan: Laying the Foundation for the Next Cooperation

After signing the contract, we learned that the customer planned to produce his yogurt bottles in the future instead of relying on purchasing finished bottles. The Gondor team immediately introduced our professional solutions in the field of packaging bottle production equipment to the customer, and this exchange laid a good foundation for the next cooperation between the two parties.

Customer Trust Is the Driving Force for Gondor to Move Forward

This cooperation with Ghanaian customers once again demonstrates the competitiveness and attractiveness of Gondor equipment in the global market. From the initial inquiry to the factory inspection and signing, our team has won the trust of customers with professional products, transparent processes, and efficient communication.

If you are also interested in our batch pasteurizer or other food processing equipment, please feel free to contact us. Gondor also provides customized solutions and looks forward to working with you!