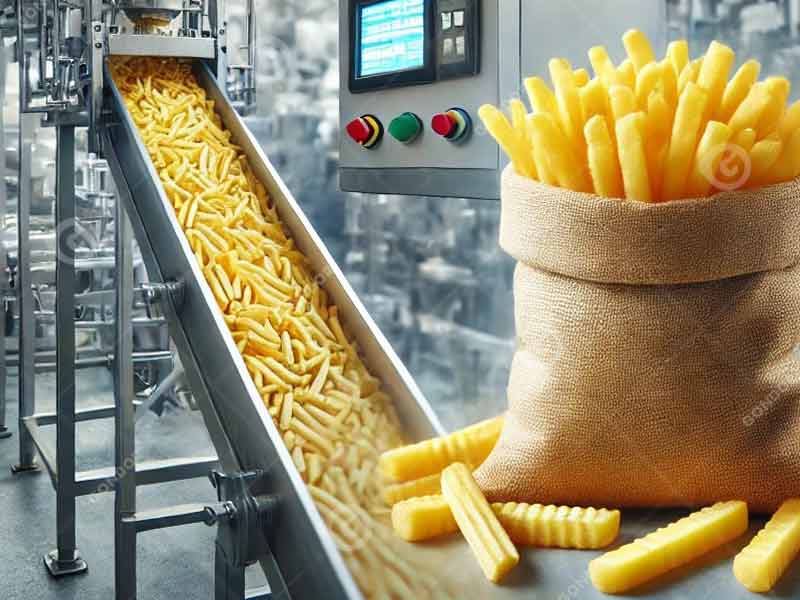

The universally cherished snack, french fries, emerges from a meticulously orchestrated process within the realms of the french fries production line, a testament to culinary engineering that transforms humble potatoes into a gastronomic delight. This exploration sheds light on the intricate stages that culminate in the creation of these delectable fries.

Main Process of French Fries Production

The process of producing French fries is a carefully orchestrated operation, involving a series of precise steps that ensure quality, taste, and texture. Check the detailed production process for the perfect French fries:

1. Meticulous Selection and Precision Sorting of Potatoes

Embarking on this culinary journey, the quintessence of french fries lies in the meticulous selection of the right variety of potatoes. Optimal for frying, these potatoes boast a high starch content juxtaposed with a low sugar composition, a harmonious blend ensuring the exterior’s quintessential crispness and an interior that’s delightfully fluffy. Post-harvest, a precision-driven sorting process ensues, establishing consistency in size and quality, pivotal for uniform culinary execution.

2. Thorough Washing and Mechanical Peeling: Paving the Way for Perfection

Subsequent to sorting, an intensive washing phase purges the potatoes of any terrestrial impurities. This phase seamlessly transitions into mechanical peeling, a cornerstone in large-scale production, pivotal in sculpting the fries’ final aesthetic appeal.

3. Strategic Cutting and Sizing: The Blueprint of the Classic Fry

Post-peeling, a strategic cutting phase ensues, sculpting the potatoes into the iconic french fry shape. This phase is underscored by a commitment to precision, ensuring uniformity in cooking. The fries’ dimensions, a subject of preference, are typically standardized, echoing the commitment to consistency of potato chips production line.

4. Blanching: A Multifaceted Process in Texture and Flavor Enhancement

Blanching, a multifaceted process, involves immersing the cut fries in hot water, a step that serves a trinity of purposes: mitigating excess sugars to prevent over-browning, tenderizing the fries, and setting the stage for the quintessential crispy texture upon frying.

5. Drying: The Crucial Prelude to Frying

Emerging from the blanching waters, the fries undergo a drying process, a critical prelude to frying. This phase is instrumental in expunging excess moisture, a step that guarantees the fries’ resistance to sogginess during frying and contributes significantly to their final crispness.

6. Frying: The Culmination of Flavor and Texture

At the heart of the production line, the frying process unfolds, a stage where the fries are bathed in oil at meticulously controlled temperatures. It is here that they acquire their golden hue and signature crisp texture. The frying parameters, including time and temperature, are meticulously calibrated to strike a harmonious balance between crunch and tenderness.

8. Packaging: The Final Step in a Journey of Culinary Excellence

Concluding this journey, the fries are packaged, a process that, in the case of frozen varieties, involves sealing them in bags designed to maintain freshness and quality. The packaging also serves as a vessel of information, encompassing ingredients, nutritional value, and cooking instructions.

Conclusion

The french fries production line stands as a paragon of food engineering, transforming the simple potato into a universally adored delicacy. Each stage, from the initial selection to the final packaging, is meticulously crafted to ensure the end product is not only delectable but also adheres to the highest standards of quality and consistency. As one indulges in a serving of french fries, it’s worth pondering the elaborate and intricate process that lies behind their creation. Please contact Gondor machinery to get more details here!