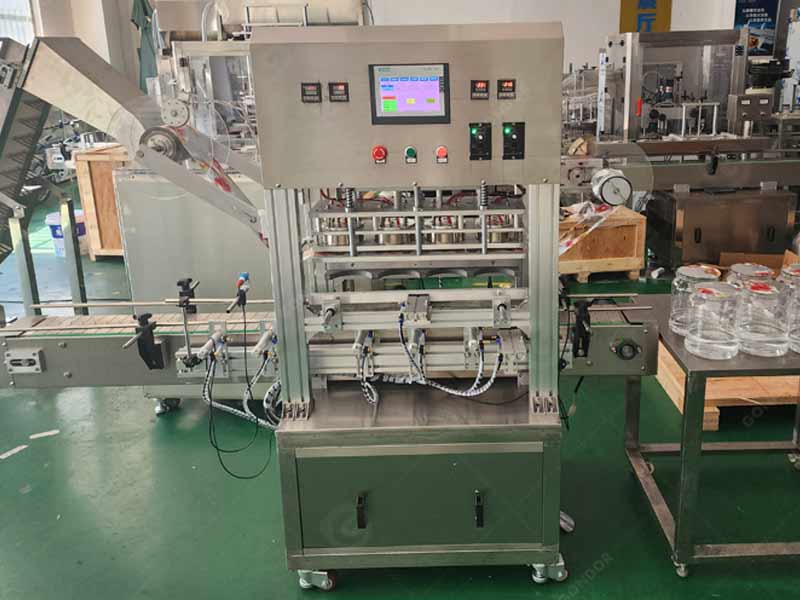

In the modern packaging industry, the aluminium foil sealing machine has become key equipment to improve production efficiency and ensure product sealing. Whether it is food, medicine, cosmetics, or industrial products and electronic products, high-quality sealing technology is crucial. Our heat press sealing machines use advanced hot melt technology and high-precision pressure control to ensure that the packaging bags are tightly sealed, moisture-proof, and pollution-proof, greatly improving product quality and shelf life.

| Model | GD-AFSM |

| Stable Voltage | 220V/380V |

| Rated Power | 1000/1200/1500W |

| Output | 1400/2100/2800 boxes/hour |

| Diameter | 85/100MM (Customizable according to the product) |

| Adjustable Temperature Range | 0-200℃ |

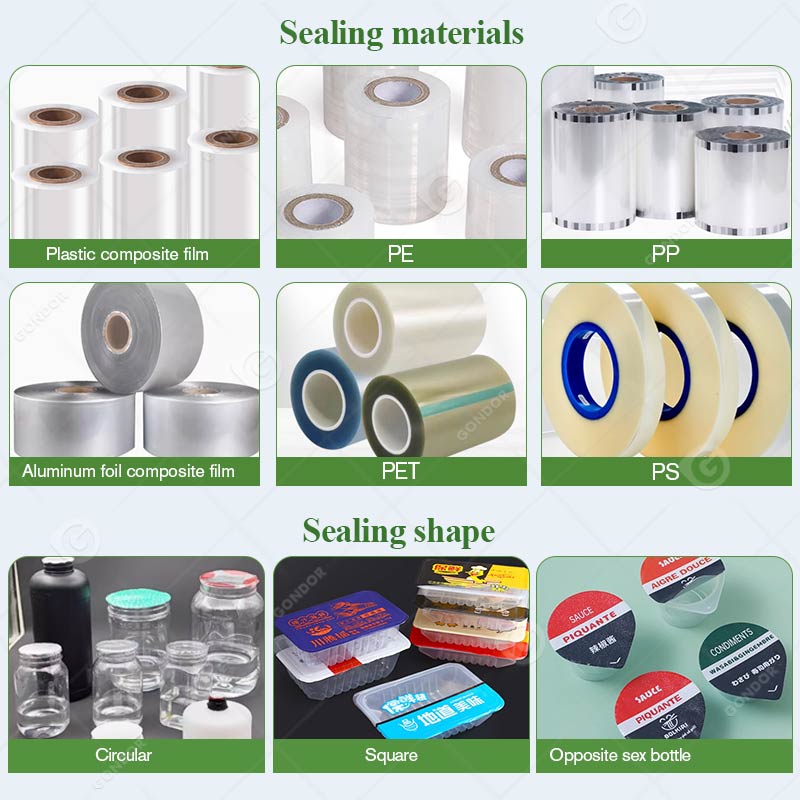

| Sealing Material | plastic composite film, aluminum foil composite film, PP, PE, PET, PS |

| Sealing Film Cutting Size | 2-3mm larger than the cup mouth, ensuring a tight seal and an aesthetically pleasing appearance |

| Weight | About 185KG |

| Dimensions | 1710x860x1710mm |

Applicable Markets for Aluminium Foil Sealing Machine

This aluminium foil sealing machine is suitable for packaging needs in various industries around the world, especially in the following industries:

Our equipment is suitable for various packaging bags, such as aluminum foil bags, plastic bags, composite bags, etc., to meet different packaging needs.

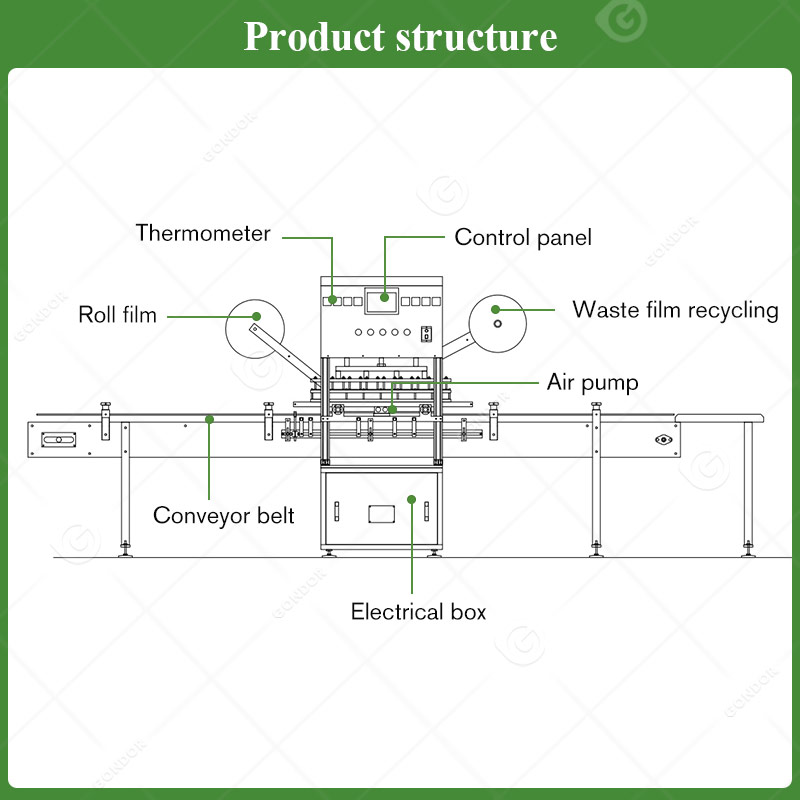

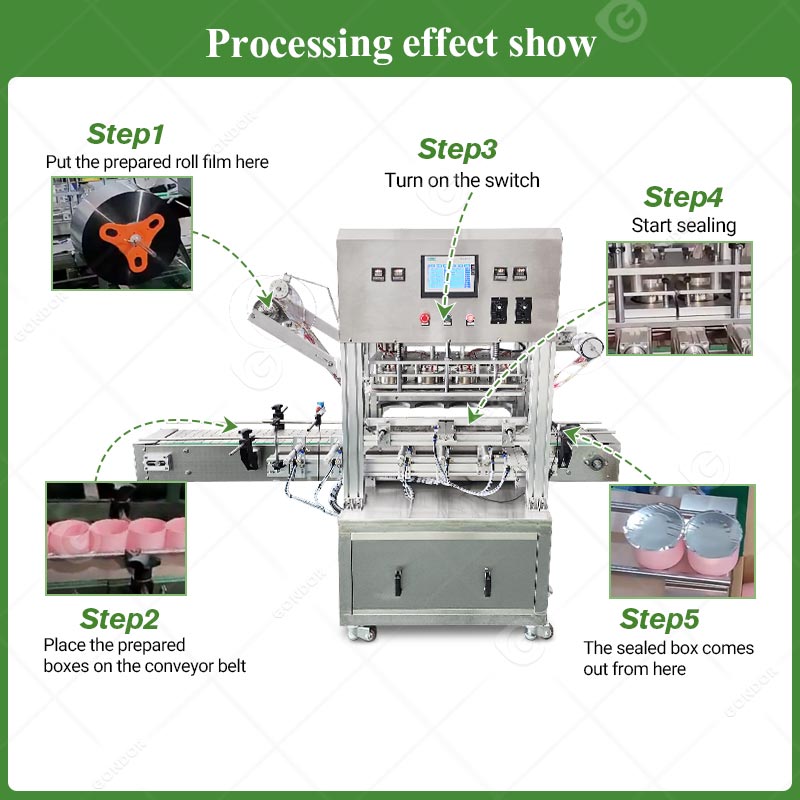

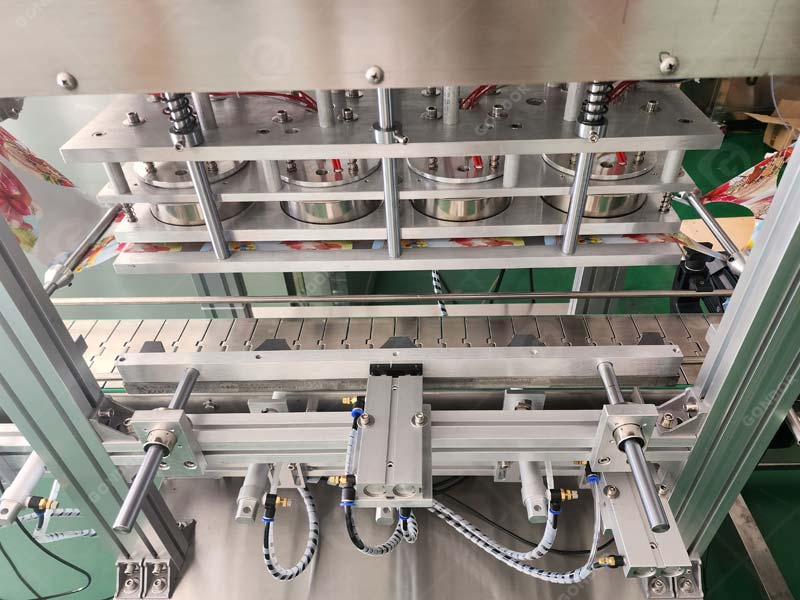

The Core Function of Heat Press Sealing Machine

The machine is equipped with an adjustable conveyor speed system, which can freely adjust the sealing speed according to different product packaging requirements, improve production efficiency, and adapt to various production line requirements.

Adopting a PLC intelligent control system and equipped with a Siemens touch screen, the operation is intuitive and simple. Users can set the sealing temperature, pressure, and time with one key, which greatly reduces the difficulty of operation and improves production safety.

High-pressure sealing technology ensures a tight seal, which not only prevents the contents from leaking, but also effectively isolates the air, maintains the freshness of the product, and improves moisture-proof and anti-oxidation effects.

The heat sealing temperature can be accurately adjusted according to the packaging bags of different materials to ensure the best sealing effect and prevent overheating or loose sealing.

It can be applied to bottles, cans, cups, and bagged products of different shapes and sizes, meet a variety of packaging needs, and is widely used in a variety of industries.

Equipped with film rolling equipment, it can automatically recycle waste film, reduce material waste, and improve environmental benefits.

Adopt an energy-saving heating system to reduce power consumption, improve heating efficiency, and reduce environmental pollution, which meets modern environmental protection standards.

Contact Gondor to Optimize Your Packaging Line

In addition to the aluminium foil sealing machine, we also offer a range of advanced packaging equipment, such as:

- Heat Shrink Tunnel Machine – Tightly wrap products with heat shrink film to improve the dust, moisture, and scratch resistance of packaging, while improving the appearance of products.

- Double Vacuum Sealer – Extend the shelf life of food, medicine, and other products to prevent oxidation and contamination.

- Labeling Machine – Fast and efficient automatic labeling to improve the appearance of product packaging.

If you are looking for efficient, durable, and intelligent sealing equipment, please contact us for more product details and quotes! We look forward to working with you to create a more efficient packaging production line!