Automatic Dough Rounder: Your Key to Efficient Bun Production

An automatic commercial dough bun divider rounder is a versatile machine that seamlessly integrates the processes of cutting, dividing, and shaping dough. Primarily available in fully automatic and semi-automatic models, it is designed for remarkable ease of use. Operators simply place a large batch of dough into the feed inlet, and the machine automatically completes precise dividing and consistent rounding. This results in highly uniform portions and perfectly shaped dough balls, which are fundamental to achieving professional-grade buns.

Furthermore, the benefits of this technology are substantial. The high accuracy in portioning, combined with excellent rounding results, directly translates to significantly enhanced production efficiency and superior, standardized product quality. Machines like the Gondor bun divider rounder boast wide applicability across various dough types, bringing immense convenience to bakery and pasta production. As such, it has become an indispensable and powerful assistant for any serious food processing business aiming to scale and refine its output.

| Product type | Semi-automatic | Automatic |

| Dimension | 580*740*1360mm | 680*600*2060mm |

| Voltage | 220V/380V | |

| Power | 0.75KW | 1.5KW |

| Weight of single dough | 30-100g/20-70g | |

| Capacity | 30/36pcs/times | |

| Molding time | 6-10seconds/times | |

| Net weight | 288KG | 570KG |

| Standard equipped | Three plastic moulding plates | |

Wide Market Scope of Gondor Commercial Dough Rounder

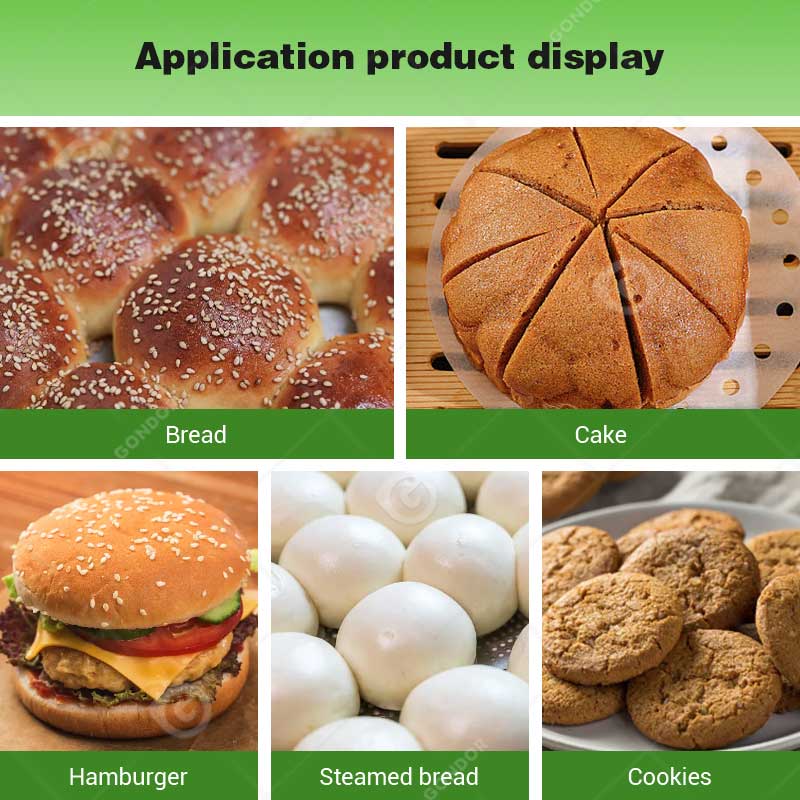

Various bakeries, steamed bun factories and other enterprises have high requirements for the efficiency and quality of dough slitting and rounding. This equipment can meet their large-scale production needs, improve production efficiency and product standardization.

The pastry departments of medium and large restaurants and hotels need to make a large number of dough foods, such as steamed buns, glutinous rice balls, etc. This machine can quickly process dough, save manpower and time costs, and ensure the timeliness and consistency of food supply.

Help the central kitchen to efficiently produce dough products, provide food processing and distribution services for multiple catering stores or units, and meet large-scale distribution needs.

Small bakeries, bun shops, etc. use this machine to improve production efficiency and product quality, gain an advantage in market competition, and the operation is relatively simple.

Used for teaching demonstrations and student practical operations, help students become familiar with the mechanized process of dough slitting and rounding, and master relevant food processing skills.

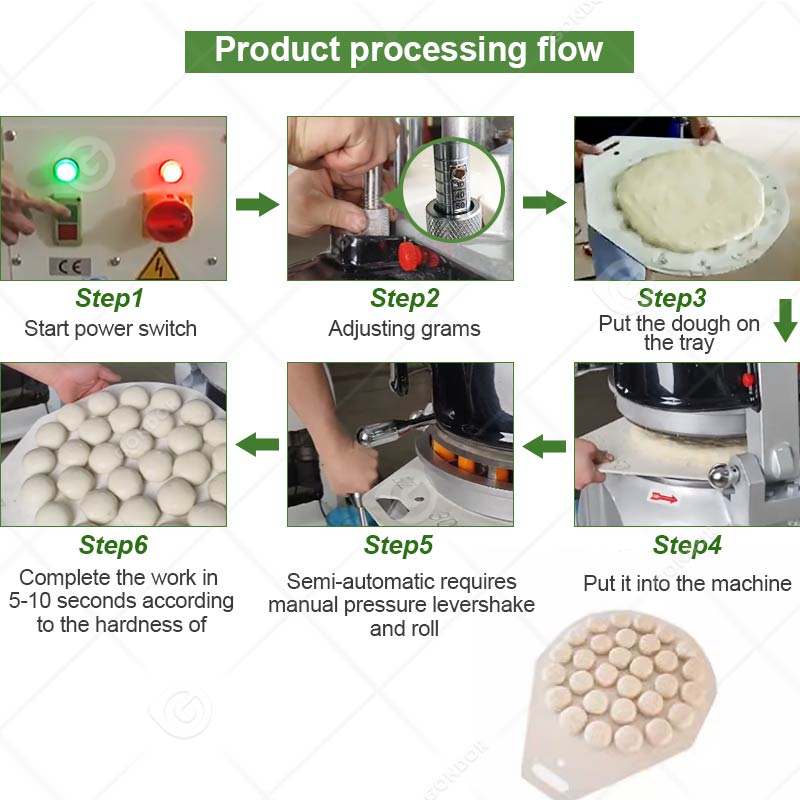

Gondor Machinery Bun Divider Rounder Usage Process

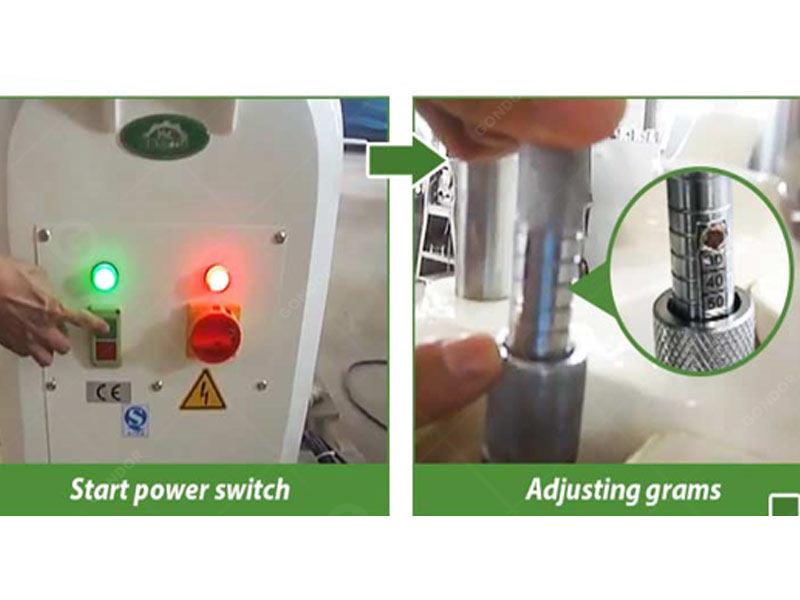

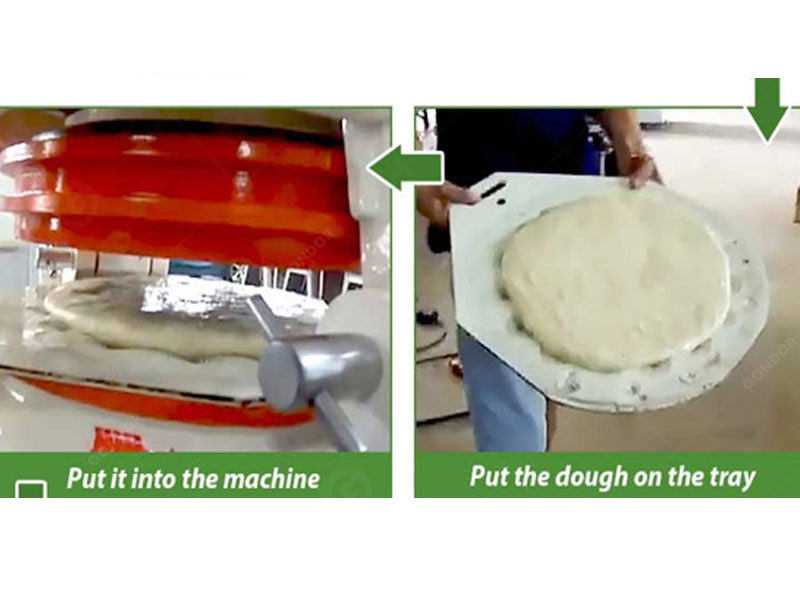

- Spread the prepared dough evenly and flatly on the material tray, then gently place the material tray into the machine. Keep it stable when placing it to avoid the dough shifting or the material tray tilting.Place the Dough

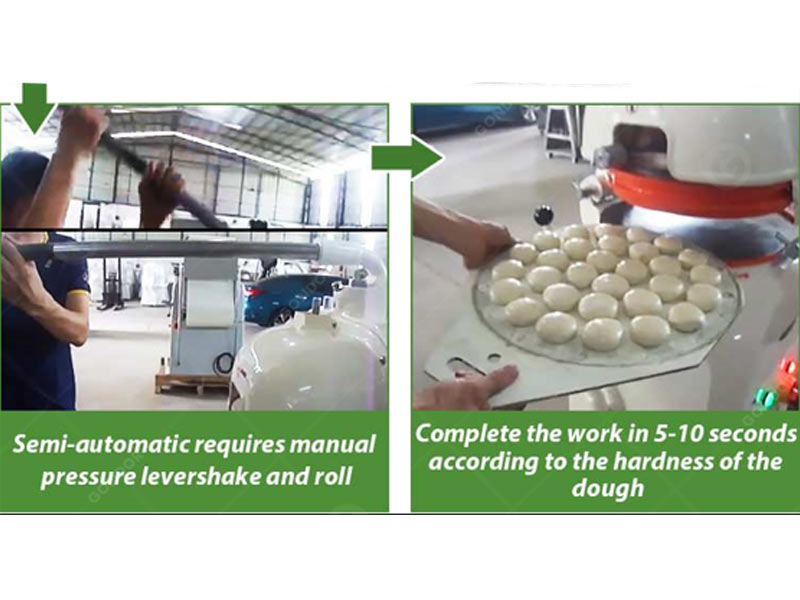

- Start the machine. If it is a semi-automatic model, you need to manually operate the pressure rod. When operating the pressure rod, control the strength to ensure that the dough is smoothly cut and rounded.Start the Machine

- Depending on the hardness of the dough, the machine will complete the work within 5 to 10 seconds. After completing the work, take out the material tray and the cut and rounded dough in time for the next processing or treatment.Complete the Work

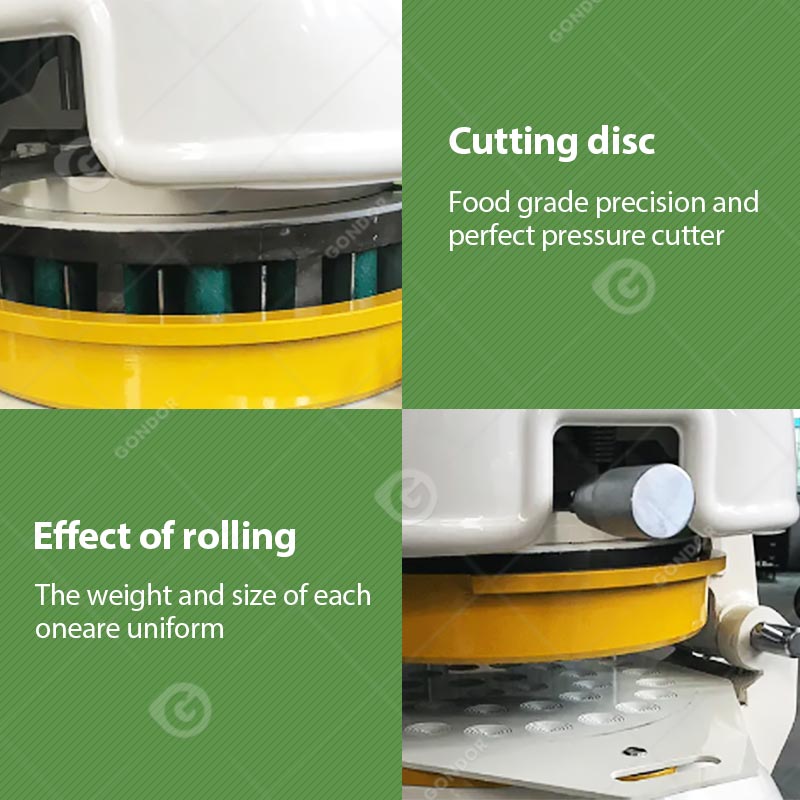

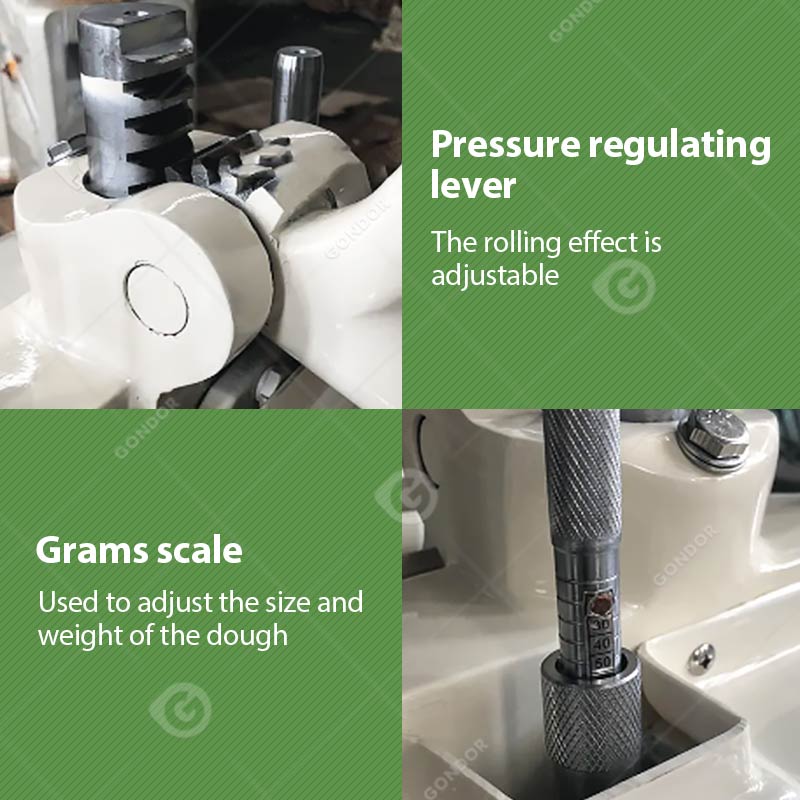

Unique Mechanical Characteristics of Gondor Automatic Dough Rounder

Assembled with materials from Taiwan, selected imported accessories to increase service life. Sturdy, durable and safe, quality guaranteed.

Humanized design, split and rolled at one time. Quick completion in 13 seconds, high efficiency, simple operation, and labor cost saving.

Through and uniform beating, non-sticky and good rolling. Ensure good dough processing effect and improve product quality.

Cast iron and stainless steel frames are strong and stable, providing strong support for the stable operation of the equipment.

304 stainless steel polished blades, non-sticky processing. Accurate cutting and improved work quality.

Automatic segmentation is uniform, greatly improving efficiency. Reduce manual operation and increase work speed.

Gondor Automatic Commercial Dough Bun Divider Rounder – Start an Efficient Pasta Journey

Dear customers, when you are looking for a solution for efficient pasta processing, the Gondor commercial dough rounder is undoubtedly the ideal starting point. Both this equipment and another star equipment of our company, the conical dough rounder, can improve the dough processing efficiency to a new level with accurate cutting and fast and even rounding. From the bakery, steamed bread factory to the pastry department of the restaurant, you can easily meet the demand of large quantities of orders and realize a stable and efficient production rhythm. Choosing Gondor means choosing a solid road to high efficiency and quality. Let us help you grasp the key links in production, inject continuous kinetic energy into your career and work together to create a broader future.