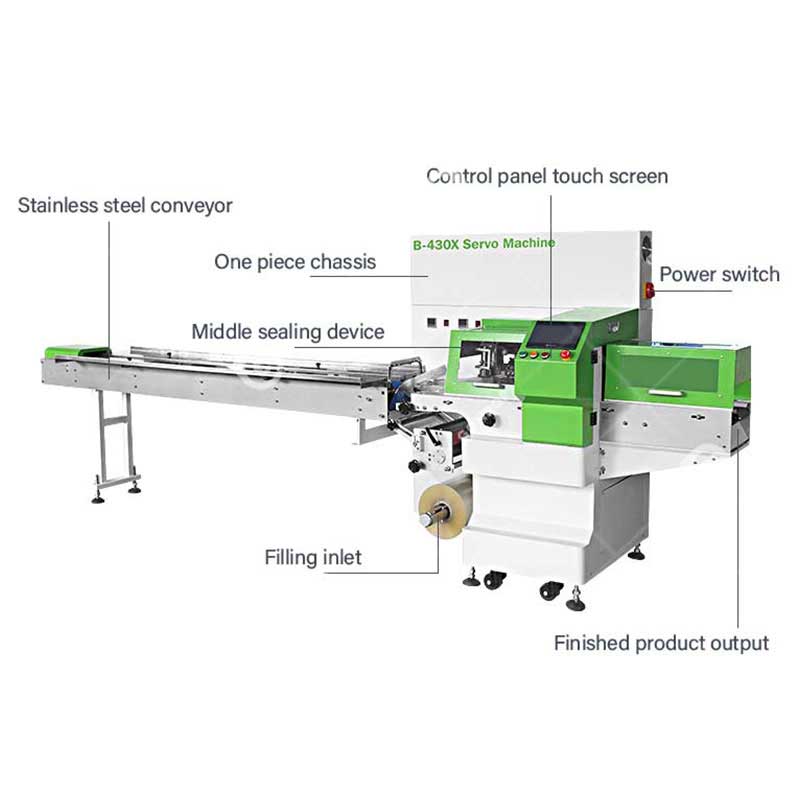

Gondor Automatic Pillow Pack Machine

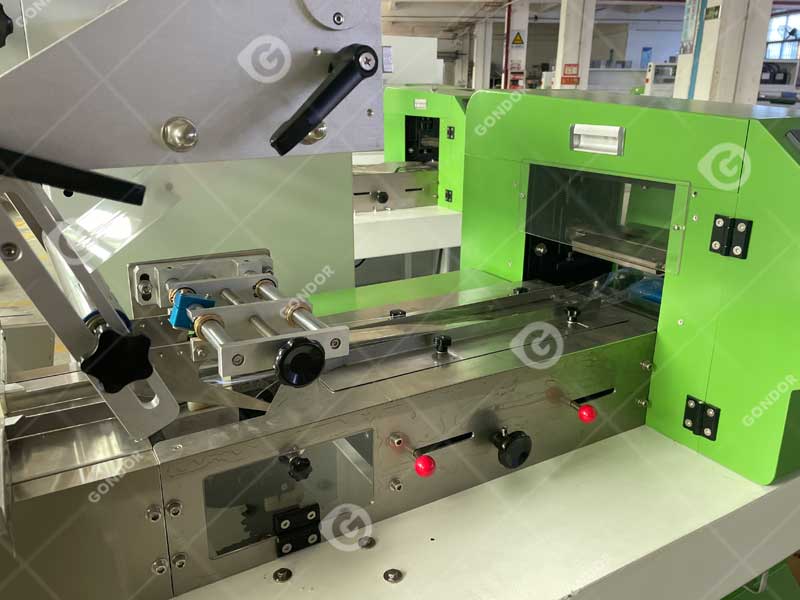

Automatic pillow packing machine is an automatic equipment widely used in packaging of various products. It consists of conveyor belt, film unwinding and traction system, sealing and cutting device, control system and other parts. In addition, the working principle of the equipment is to put the product on the conveyor belt and move it at a constant speed. The packaging film is formed into a cylinder by the former, and the product is wrapped in it. Then, after the sealing and cutting process, the product packaging is completed.

Automatic Pillow Packing Machine Specification

|

Model

|

XZL-250

|

XZL-320

|

XZL-350

|

XZL-450

|

XZL-600

|

|

Width of the film

|

Max250mm

|

Max320mm

|

Max350mm

|

Max450mm

|

Max600mm

|

|

Length of the bag

|

65-190/120-280 90-220mm

|

5-190/120-280 90-220/150-330mm

|

65-190/120-280 90-220/150-330mm

|

130-450mm

|

120-500mm

|

|

Width of the bag

|

30-110mm

|

50-160mm

|

50-160mm

|

50-180mm

|

100-280mm

|

|

Products are highly

|

Max.40-55mm

|

Max.40-60mm

|

Max.40-60mm

|

Max.75mm

|

Max.110mm

|

|

Roller diameter

|

Max.320mm

|

||||

|

Packing speed

|

40-230bag/min

|

40-230bag/min

|

40-230bag/min

|

30-150bag/min

|

20-230bag/min

|

|

Power

|

2.4kw

|

2.6kw

|

2.6kw

|

3.2kw

|

3.6kw

|

|

Size

|

3770*670*1450

|

3770*720*1450

|

4020*770*1450

|

4020*820*1450

|

4020*920*1460

|

|

Weight

|

450kg

|

500kg

|

580kg

|

650kg

|

680kg

|

|

Optional configuration

|

Code punching machine inflatable device cake falling machine material handling machine

|

||||

|

Packaging materials

|

Such as single heat seal BOPP/ composite film;Such as OPP composite PE PET composite PEE

|

||||

|

Bag shape

|

Back seal packaging (round hole and butterfly hole can be customized)

|

||||

|

Transverse seal edge grain

|

Mesh type sealing, stripe type sealing, knife edge serrated mouth,flat mouth plus v easy to tear

|

||||

Gondor Pillow Pack Machine Application Industry

- Packaging of biscuits, bread, candy, instant noodles, etc.Food Industry

- Packaging for medicines, capsules, pills, etc.Pharmaceutical Industry

- Such as small parts, screws, nails, etc.Hardware Industry

- Pencils, erasers, rulers and other stationery packaging.Stationery Industry

- Packing for products such as toothbrushes, toothpaste, soap, and tissues.Daily Necessities Industry

- Such as the packaging of batteries, electronic components, and so on.Electronics Industry

- For example, packaging for chemical products such as laundry detergent, dishwashing liquid, and laundry detergent.Chemical Industry

Features of Gondor Pillow Packaging Machine

Efficient Packaging

Dual inverter control, flexible bag length cutting, capable of high-speed continuous packaging.

Easy Operation

Friendly human-machine interface, convenient and fast parameter setting.

Safe and Reliable

Fault self-diagnosis function, fault display is clear at a glance.

Strong Stability

Stable operation, few faults, and reduced downtime and maintenance time.

Accurate Positioning

High-sensitivity photoelectric color mark tracking, digital input cutting position, making sealing and cutting more accurate.

Energy Saving and Environmental Protection

Using advanced energy-saving technology to reduce energy consumption.

Compatibility of High-Quality Packing Materials

Temperature independent PID control, suitable for various packaging materials.

Flexible Adjustment

It can be quickly adjusted according to the size and packaging requirements of different products.

Automatic Pillow Packing Machine – A New Realm of Packaging

If you are looking for a suitable packing machine, our automatic pillow packing machine is definitely your choice for efficient packaging! It has excellent performance and is easy to operate. Whether it is food, daily necessities, or medicine, hardware and other products, it can achieve perfect packaging. And it can also be flexibly adjusted to adapt to various sizes. Choose Gondor pillow packing machine to improve packaging quality and efficiency, put on a gorgeous coat for your products, and start a new journey of success!