With the development of healthy eating trends, rice noodles, rice vermicelli, and vermicelli are popular because of their low fat, easy digestion, and good taste. Our rice vermicelli machine is suitable for all kinds of food processing enterprises, from small workshops to large factories, and can support corn, sorghum, millet, mung beans, and other grain raw materials to meet the traditional needs of Asia, while expanding the gluten-free food market in Europe and the United States, and help efficient and diversified production.

| Model |

GD-VRNM-1 |

GD-VRNM-2 |

GD-VRNM-3 |

| Capacity |

100kg/h |

50-60kg/h |

200kg/h |

| Power |

11kw |

9kw |

18.5kw |

| Size |

800*720*1650mm |

1030*460*1460mm |

1120*790*1900mm |

| Weight |

350kg |

100kg |

600kg |

| Packing Size |

900*820*1750mm |

1270*600*1750mm |

1320*990*2100mm |

| Packing Weight |

410kg |

160kg |

710kg |

Application Scenarios of Vermicelli Machine

Meet the needs of China, Vietnam, Thailand and other countries for traditional rice noodles, rice vermicelli, and vermicelli, and provide stable and efficient production solutions.

European and American Market

Respond to the trend of healthy diet and produce gluten-free noodles to cater to the vegetarian and healthy food markets.

Africa and South America Market

Support the use of local specialty crops as raw materials, such as corn, sorghum, etc., to make nutritious grain noodles.

Automatic Vermicelli Making Machine Outstanding Equipment Features

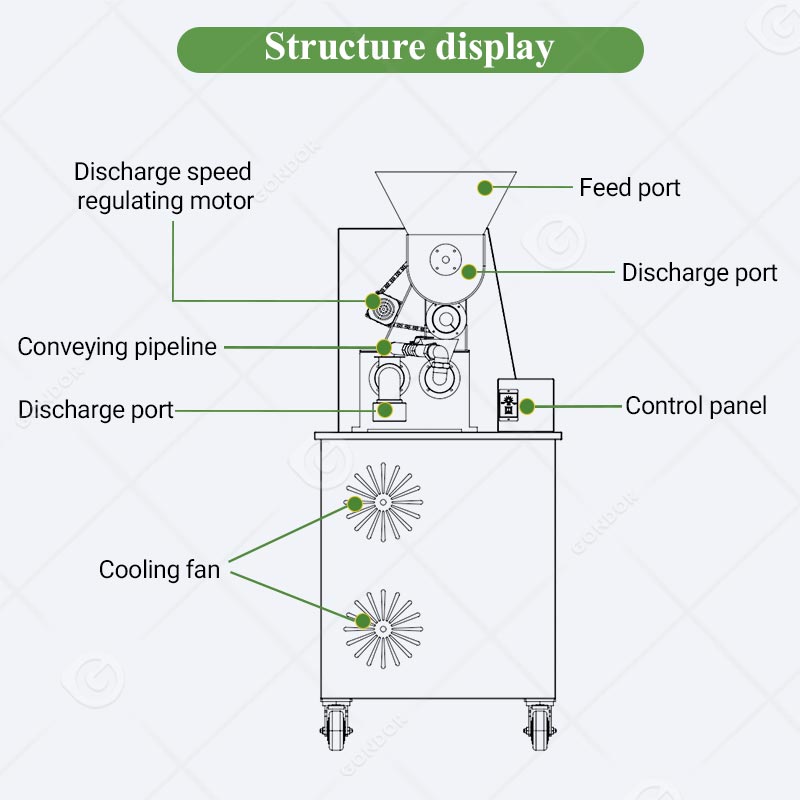

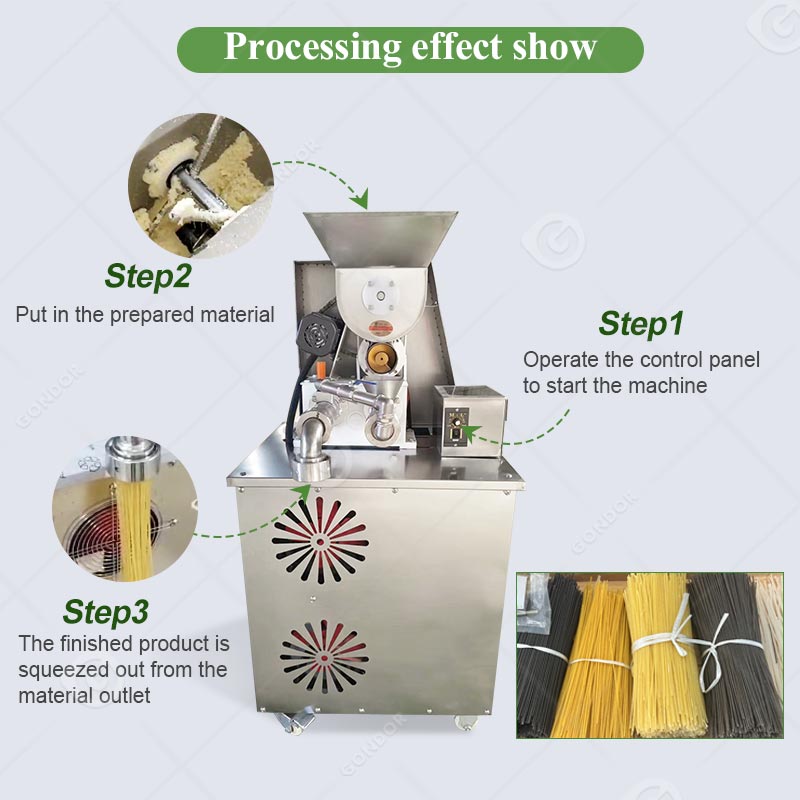

Self-cooking & Molding

The production of traditional rice noodles often requires multiple steps such as steaming, kneading, and manual molding. Our Rice Noodle Machine uses advanced Extrusion Technology to allow rice noodles to be automatically matured and molded inside the machine, greatly improving production efficiency and reducing labor costs.

Adjustable Thickness

Different markets have different requirements for rice noodles. Some prefer Thin Vermicelli and some prefer Thick Rice Noodles. This machine is equipped with Customizable Molds to support production of multiple specifications to meet different market needs.

Powerful Air Cooling System

The Dual-Fan Cooling System is used to quickly cool down the rice noodles after extrusion molding to prevent the rice noodles from sticking or breaking due to excessive temperature, ensuring that the finished product has a better taste and a more stable shape.

Intelligent Control Panel

The clear and intuitive One-Touch Operation panel allows operators to quickly get started without complex training. The equipment has a high degree of automation, reducing human errors and improving production efficiency.

Variable Frequency Motor

This equipment is equipped with a Frequency Conversion Speed Motor, which can accurately control the feeding speed to ensure uniform discharge of rice noodles and avoid production problems caused by uneven feeding.

Versatile and Multi-Functional

In addition to producing rice noodles and vermicelli, this machine can also process cold noodles, sweet rice cakes, corn noodles and other foods, realizing multi-functional integration, helping enterprises optimize production and expand product categories.

Why Choose Rice Vermicelli Machine from Gondor?

High Efficiency User-FriendlyDurable & Stable CustomizableEnergy-Saving

Automated operation greatly increases production capacity and reduces labor costs.

Intelligent control system, quick start, no need for professional technicians.

Made of high-quality materials, stable operation and long service life.

A variety of molds are available to meet different market needs.

High-efficiency motors, low energy consumption, and reduced production costs.

Extended Recommendation – With Other Food Processing Equipment

If you are interested in rice vermicelli machine, or want to further expand the production line, we also provide a variety of related food processing equipment, such as:

- Dough Kneading Machine: Suitable for the production of noodles, steamed buns, dumpling wrappers and other noodle products.

- Macaroni Production Line: Produces different types of pasta such as spaghetti, macaroni, and wide noodles.

- Vegetable Cutter: Suitable for cutting and processing vegetables to improve food processing efficiency.

Welcome to contact us for more product information and customized solutions! Make your food processing more efficient and diverse, and help companies move towards the global market!