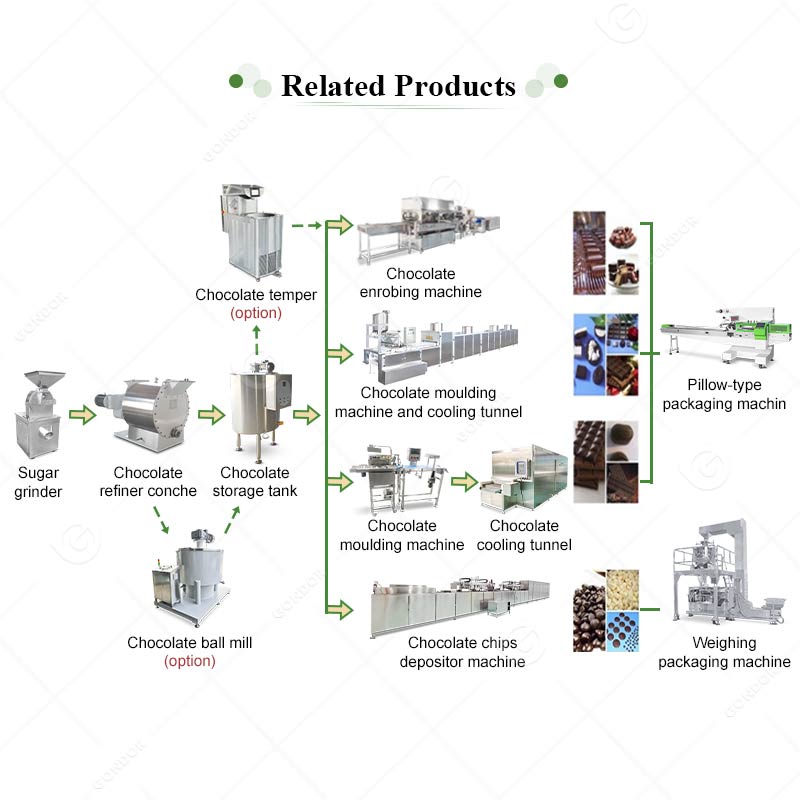

Gondor Chocolate Drip Production Line Introduction

The chocolate drip production line is a fully automated system designed to create uniform chocolate droplets or drips in various shapes and sizes. The process starts with tempered chocolate being deposited through precise depositing heads onto a conveyor belt.After cooling and solidifying in a cooling tunnel, the chocolate droplets are automatically separated and ready for packaging or further processing.

This chocolate dripping production line is ideal for mass production, offering high efficiency, consistent quality, and precise control over chocolate flow. It is commonly used for producing chocolate chips, drips, and small-sized chocolate pieces for use in baking, confectionery, and other food products.

Gondor Chocolate Dripping Machine Models

With 20 years of dedicated experience in food machinery manufacturing, we specialize in offering a diverse range of chocolate depositing equipment models—thus perfectly catering to your unique production requirements. Simply reach out to us, and we will proactively deliver tailored, satisfactory services that align with your expectations.

| Model |

GD400 |

GD600 |

GD800 |

GD1000 |

GD1200 |

| Production Capacity |

35 (if 0.1g)

85 (if 1g) |

55(if 0.1g)

135(if 1g) |

70 (if 0.1g)

170 (if 1g) |

90 (if 0.1g)

225 (if 1g) |

110 (if 0.1g)

275 (if 1g) |

| Whole Machine Power(kw) |

11 |

12 |

18 |

18 |

23 |

| Belt Width(mm) |

400 |

600 |

800 |

1000 |

1200 |

| Machine Weight(kg) |

2300 |

2500 |

2600 |

3000 |

3400 |

| Outside Dimension(mm) |

12000*850*1600 |

12000*1050*1600 |

12000*1250*1600 |

12000*1450*1600 |

12000*1650*1600 |

| Temperature Of Cold Channel Operation(℃) |

0-10 |

| Depositing Time(time/min) |

0-20 |

| Single Grain Weight(g) |

0.1-3 |

| Machine Length(m) |

10-30 |

Gondor Chocolate Drop Making Processing Line Application

Applicable Scenarios Of The Chocolate Drizzle Production Line

Chocolate ManufacturersBaking Ingredient & Food Processing PlantsStart-ups & Boutique ChocolatiersFrozen Food FactoriesFunctional Food Factories

For large-scale production of chocolate buttons for baking, dessert decoration, or direct retail packaging.

Producing chocolate buttons as an ingredient for supply to bakeries, ice cream factories, and beverage manufacturers.

Smaller models available to meet the needs of personalized, small-batch custom production.

Used for chocolate coating production in ice cream, popsicles, and frozen desserts, maintaining stable dripping effects at low temperatures.

Adapted for chocolate coating processes in protein bars, energy balls, and meal replacement foods, achieving integrated production of nutrition and flavor.

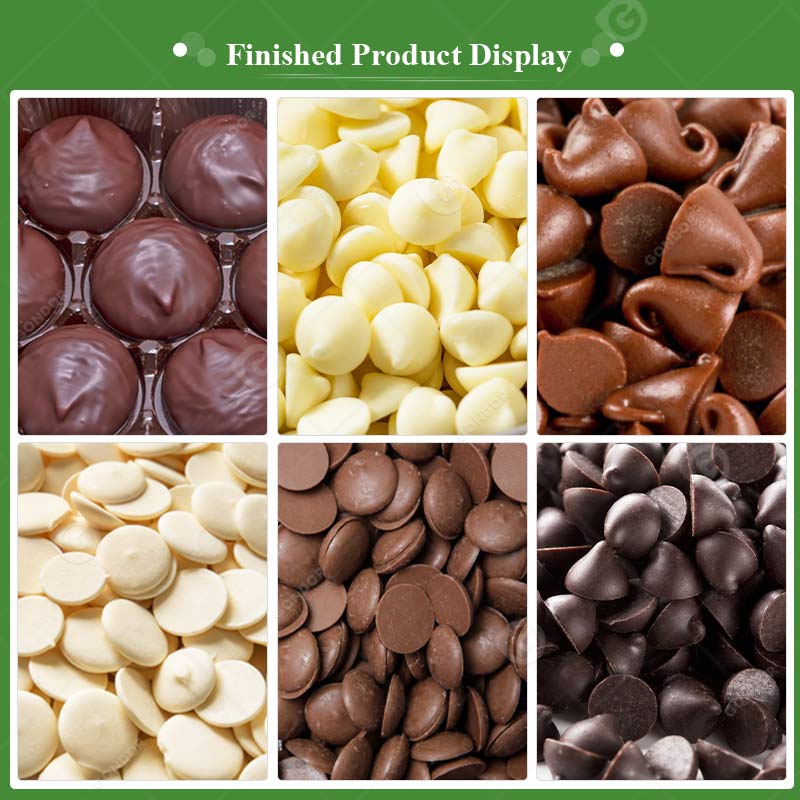

Applicable Products Of Gondor Chocolate Depositing Production Line

Gondor chocolate depositing production line is engineered to process tempered chocolate liquor. In addition to accommodating dark, milk, and white chocolate, it further handles chocolate blended with ingredients such as nut pieces or cookie crumbs.Here are some key applicable products for this chocolate depositing equipment.

Pure Chocolate Beans/PodsSolid/Liquid Sandwich ChocolateChocolate-Coated Nuts/Dried FruitsChocolate Dripping Baked GoodsChocolate-Coated Energy Bars

Pure chocolate products of uniform size are mass-produced through precise drip pouring technology, suitable for many scenarios such as direct supply of snacks and baking ingredients.

Supports precise wrapping of different fillings such as nuts and jams, achieving seamless integration of chocolate shell and filling, and rich taste.

Evenly wrap cashews, dried strawberries and other ingredients to form a uniformly thin chocolate shell, creating a casual snack.

Dripping or drawing patterns on the surface of baked products to simultaneously enhance the appearance and chocolate flavor of the product.

Suitable for functional food production, evenly coating the surface of protein bars, taking into account nutrition and silky taste.

Gondor Chocolate Drop Line Details

User-Friendly Control System

Integrated with PLC (Programmable Logic Controller) and touch-screen HMI (Human-Machine Interface), it facilitates intuitive setting of production parameters (e.g., temperature, speed), real-time operational status monitoring, and efficient troubleshooting—delivering a straightforward, user-centric operating experience.

High-Precision Chocolate Depositor

Boasts multi-head, programmable depositing modules that enable precise regulation of chocolate flow rate and application range, ensuring consistent and accurate product forming.

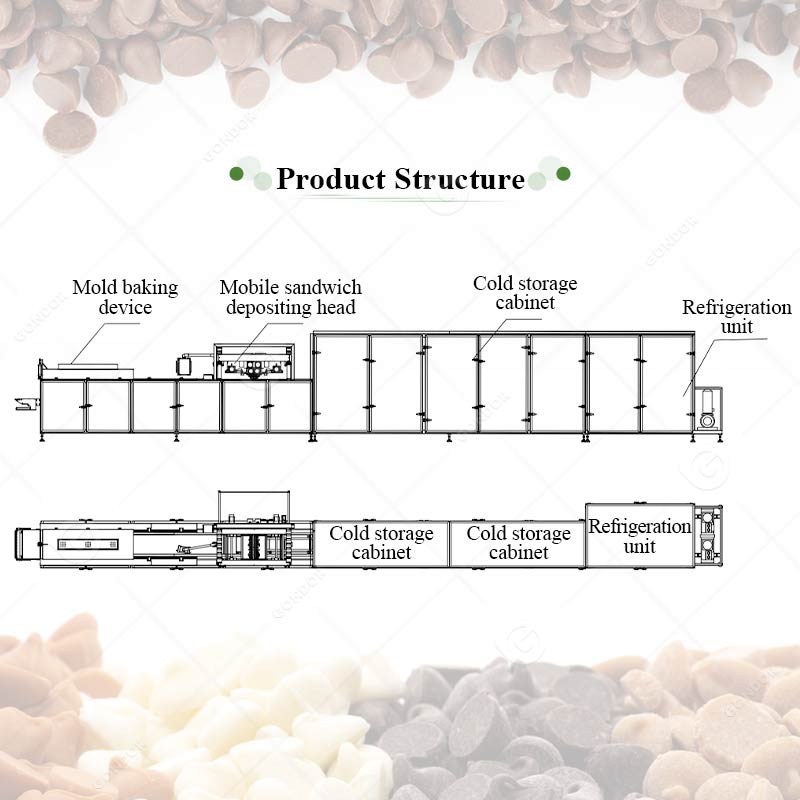

Reliable Cooling System

Integrated with a high-efficiency refrigeration unit and multi-section cooling tunnel, it promotes stable chocolate solidification following an optimal temperature profile, thus safeguarding uniform product quality and superior mold release performance.

Versatile Mold Configuration

Features a rapid mold change mechanism, supporting the production of chocolate buttons with diverse specifications. Accommodates a wide range of raw materials, including dark chocolate, milk chocolate, white chocolate, and compound chocolate coatings.

Gondor Chocolate Drip Production Line Features

Our chocolate production line not only offers you two core options—plunger-type and drum-type depositing lines—but also boasts numerous key strengths. To help you fully grasp the equipment’s value, we have outlined the detailed information below.Additionally, if you’re interested in our chocolate equipment, don’t hesitate to contact us—we’ll promptly deliver comprehensive, tailored answers to address your specific inquiries.

Adjustable Size And Thickness

By changing precise molds and adjusting the drip rate, chocolate products of different diameters, thicknesses, and shapes can be produced to precisely match individual needs.

Fully Automated Cooling And Demolding

The production line integrates automatic conveying, multi-stage cooling, and automatic demolding functions, requiring no manual intervention and significantly improving production efficiency and product consistency.

Supports Customized Production

The standard model is suitable for solid-color/mixed chopped chocolate products. By adding accessories or customizing the mold head system, special processes such as whole-nut embedding and two-tone/multi-layered designs can be achieved.

Compatible With Tempered Chocolate

Requires the use of professionally tempered chocolate sauce to ensure a smooth, glossy surface and a crisp texture, guaranteeing high-end product quality.

Strong Process Compatibility

It can mass-produce basic solid-color chocolate chips and also supports customization to fulfill diverse production requirements—such as compound ingredients and special shapes—making it suitable for a broad range of applications.