Gondor Chocolate Making Production Line Introduction

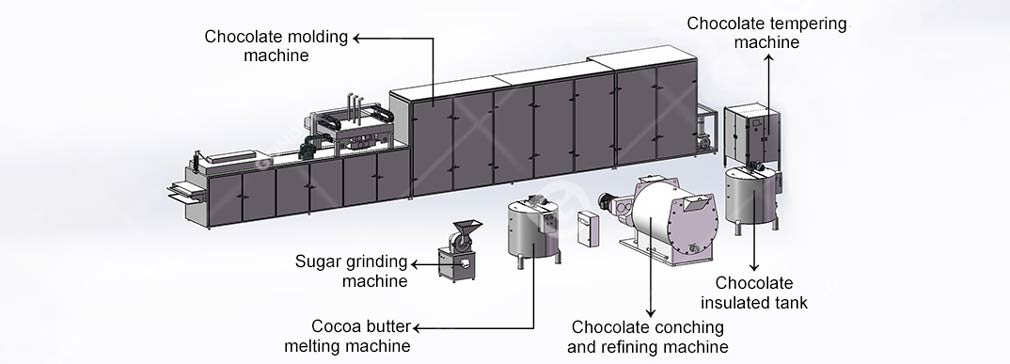

Our advanced chocolate production line is engineered for efficient, precise, and hygienic manufacturing, making it the definitive choice for any modern chocolate factory production line. By seamlessly integrating melting, tempering, molding, cooling, and packaging, this comprehensive suite of chocolate production line machinery equipment ensures smooth operation and consistent product excellence. Designed to handle various confectionery types, this high-performance chocolate making production line enables manufacturers to achieve stable, high-output goals while maintaining superior texture and appearance in every batch.

Gondor Chocolate Production Lines Models

To achieve a fully automated process from raw material handling to finished product packaging, this chocolate making production line utilizes industrial-grade high-performance components designed to maintain exceptional stability and durability in harsh production environments. Through a precise temperature control system and automated mechanical collaboration, the entire line ensures that the physical properties of the chocolate syrup reach their optimal state during grinding, tempering, and molding. The technical parameters of each core unit in the entire production line are detailed below, providing reliable data support for your large-scale production:

| Name | Power | Voltage | Weight | Size | Capacity |

| Melting Machine | 7.5kw | 380v | 860kg | 1850*1500mm | 1000L |

| Sugar Powder Grinding Machine | 3kw | / | 670*500*720mm | 10-80kg/h | |

| Chocolate Refiner Machine | 23.25kw | 2900kg | 2500*1400*1600mm | 500L | |

| Storage Tank | 3kw | / | 670*500*720mm | 10-80kg/h | |

| Chocolate Tempering Machine | 22.5kw | / | / | 250kg/h | |

| Chocolate Molding Machine | 33kw | 3600kg | 17000*1200*1800mm | 10-17 cycles/min | |

| Chocolate Packaging Machine | / | 220v | 430kg | 3940*1010*1390mm | 1-120 bags/min |

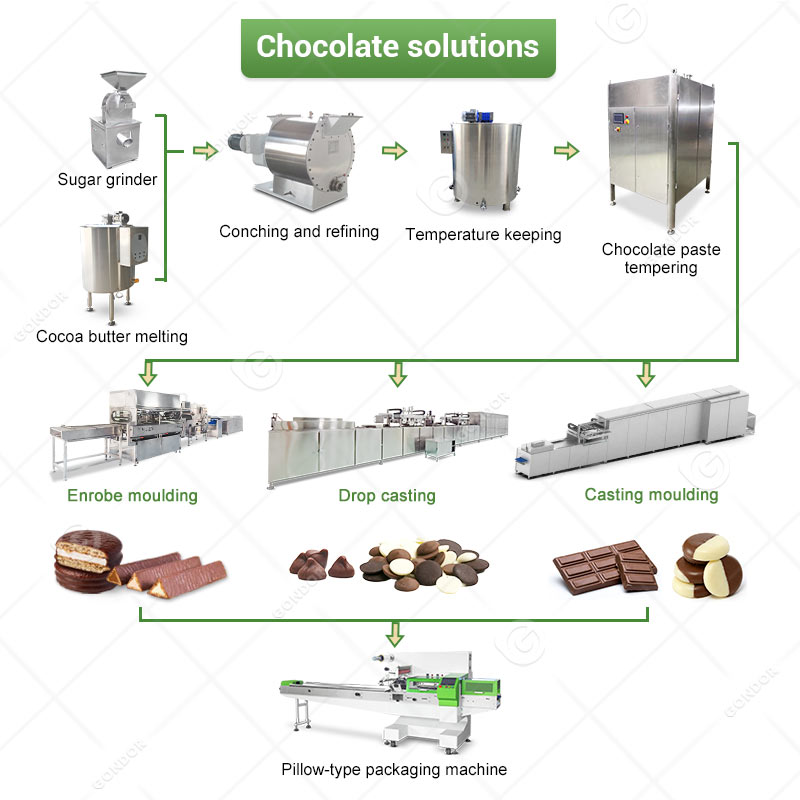

Chocolate Production Process Flow

Ingredient Preparation & Refining

- Melting & Sugar Grinding: The process begins by melting cocoa butter and cocoa liquor into a consistent liquid state while simultaneously grinding granulated sugar into an ultra-fine powder to ensure a grit-free texture.

- Refining & Conching: The liquid fats and powdered ingredients are mixed and processed in the refiner. This critical stage reduces particle size to microscopic levels and develops the chocolate’s complex aroma by removing unwanted moisture and acidity.

Stabilization & Conditioning

- Thermal Storage (Holding): The refined chocolate mass is transferred to a jacketed storage tank. Here, it is kept under constant agitation at a precise temperature to maintain its fluid state and ensure chemical homogeneity.

- Precision Tempering: The mass passes through a continuous tempering machine. By strictly controlling the cooling and reheating cycles, the cocoa butter is stabilized into “Form V” crystals, which gives the final product its glossy shine and characteristic “snap.”

Forming & Solidification

- Molding & Depositing: The tempered chocolate is precisely dosed into molds. This stage can accommodate various configurations, including solid bars, shells for center-filled pralines, or playful shapes like hearts and bears.

- Cooling & Solidification: The filled molds travel through a multi-zone cooling tunnel. Controlled airflow gradually lowers the temperature, allowing the chocolate to set firmly and contract slightly for easy removal.

Final Output

- Demolding: Once fully solidified, the chocolate pieces are mechanically released from the molds through vibration or inversion and aligned for the final stage.

- Automatic Packaging: In the final step, the products are routed to high-speed packaging machines for wrapping, ensuring the chocolate remains hygienic and preserves its premium quality until it reaches the consumer.

Raw Material Applications for Chocolate Making Production Line

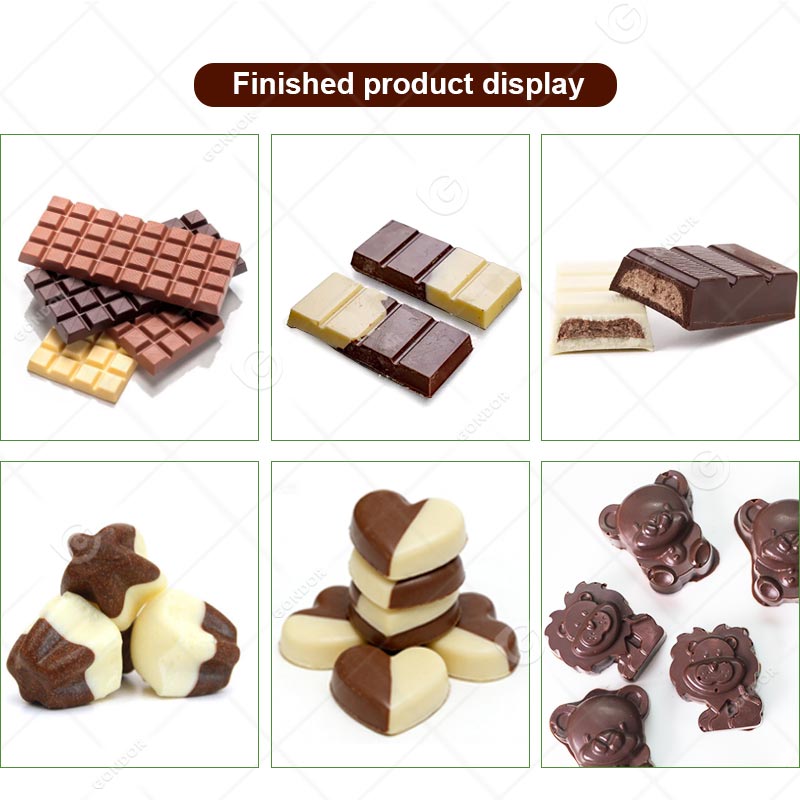

Versatile Finished Product Applications

Produces pure-textured, high-gloss bars or single-piece chocolates that perfectly showcase the rich, original flavor of cocoa.

Supports the precision injection of fruit jams, creams, caramels, or liquid fillings into chocolate shells to create a rich, layered taste experience.

Utilizes multi-head depositing technology to blend different colored masses, creating visually stunning marbled or layered effects.

Efficiently produces standard-sized chocolate bars with the option to incorporate biscuit bits, cereals, or other inclusions inside or on the surface.

Uniformly coats biscuits, wafers, or dried fruits with a silky layer of chocolate, significantly increasing the product’s flavor value.

Equipped with versatile molds to easily create playful shapes like bears, hearts, flowers, and various festive-themed designs.

Supports the production of mixtures containing whole or crushed nuts, ensuring every piece delivers a satisfying, crunchy texture.

Gondor Chocolate Making Production Line Features

- Precise Temperature Control: Utilizes high-precision PID thermal management to monitor temperature differentials in real-time, ensuring the perfect stability of the chocolate’s crystal structure.

- Uniform Molding Quality: The high-accuracy depositing heads, combined with advanced vibration de-aeration, deliver consistent product weight and a flawless, bubble-free surface finish.

- Stable Continuous Output: Built with an industrial-grade architecture to support 24/7 non-stop operation, maintaining high-volume productivity without compromising process consistency.

- Energy-Efficient Design: Features an optimized heat-recovery system and premium insulation layers that significantly reduce power consumption and lower overall operational costs.

- Modular Scalability: The modular design allows for rapid component switching and functional upgrades, such as adding center-filling or nut-sprinkling units as production needs evolve.

- Superior Hygiene Standards: Constructed entirely from food-grade stainless steel with seamless welding and a quick-disassembly design, ensuring thorough cleaning and compliance with global safety standards.

Tailored Solutions: Customizing Your Chocolate Making Production Line

We offer comprehensive customization services tailored to your specific processing requirements. From production capacity and facility floor plans to chocolate product types and the desired level of automation, we can engineer a bespoke solution that aligns perfectly with your manufacturing goals. Contact Gondor today to receive your customized technical proposal and a formal quote.