Chocolate Tempering Wheel: Precise & High-Quality

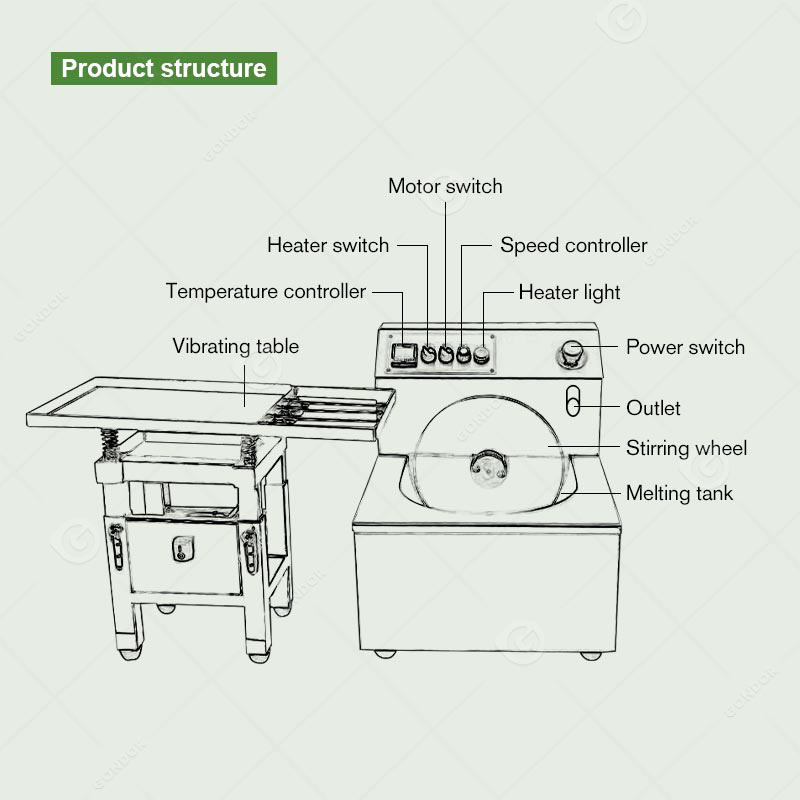

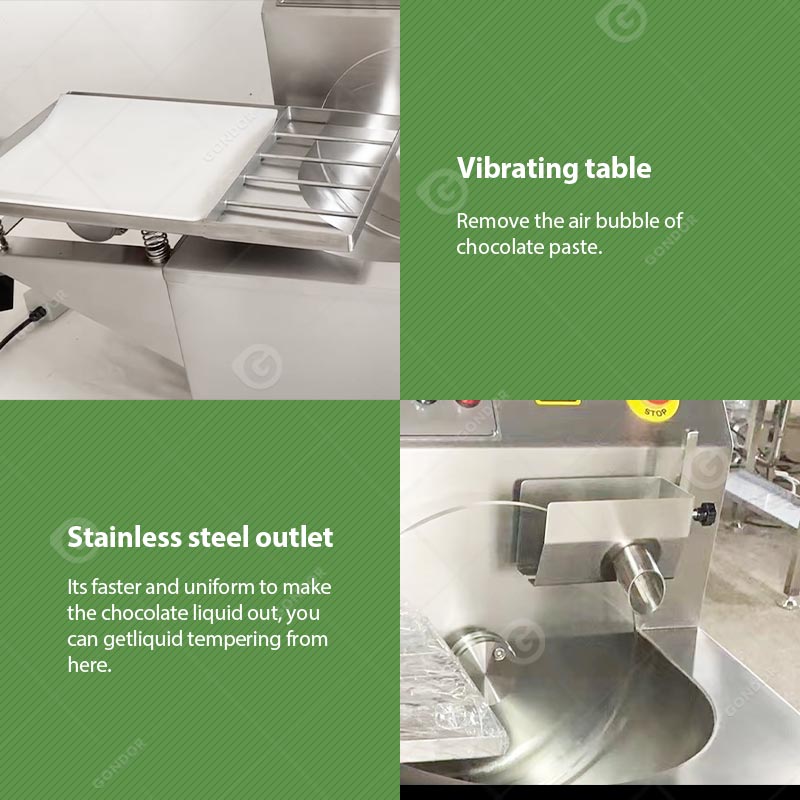

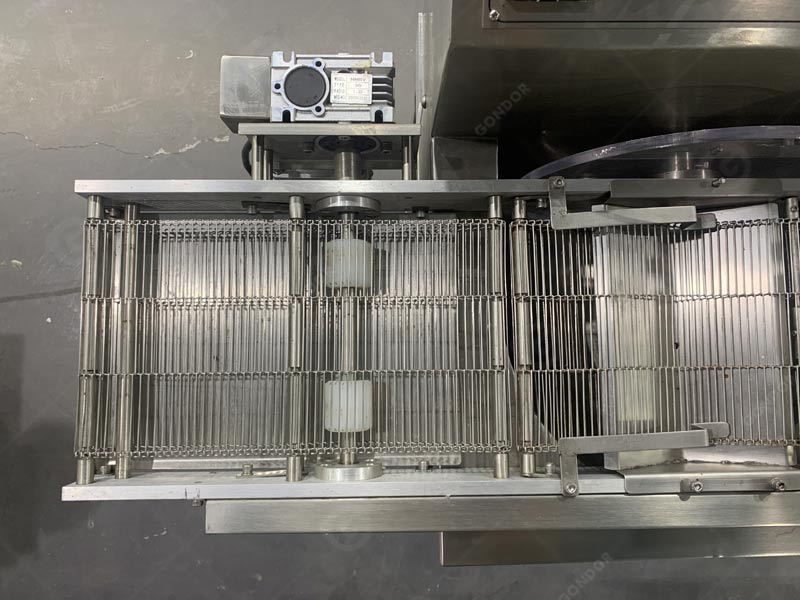

This chocolate tempering wheel, designed for food processing plants and the confectionery industry, features a full stainless steel wire-drawing process that complies with international food safety standards. Moreover, it has Siemens sensors for precise temperature control and efficient heat preservation, ensuring uniform chocolate tempering and a stable crystal structure. In addition, the machine includes an automatic stirring wheel and a vibration function, which effectively removes bubbles, resulting in a smooth surface and easy demoulding. Thanks to its compact and flexible design, it is easy to install, while the simple operation panel makes it suitable for various chocolate-making needs. Finally, the seamless combination of the temperature control system and stainless steel outlet ensures the chocolate flows evenly and delicately, making this machine an ideal choice for those who prioritise high-quality chocolate production.

Gondor Chocolate Wheel Tempering Machines

|

Model |

Capacity | Power | Voltage | Size |

| GD-CMPM-08/15 | 5kg-60kg/h | 0.6-2kw | 220v |

450*550*550mm-1220*780*1290mm |

|

GD-CMPM-30/60 |

10kg-40kg/h | 1.8-2kw | 220v |

900 * 670 *1230mm-1130 * 750*1300mm |

| GD-CMPM-15*2 | 10-30kg/h | 2kw | 220v |

1070*600*640mm |

|

GD-CMPM-24 |

15-45kg/h | 2.2kw | 220v |

1275* 660 *570mm |

Markets Targeted by the Chocolate Wheel Tempering Machine

This chocolate wheel tempering machine is widely used in a variety of chocolate-making scenarios due to its advanced temperature control technology, precise structural design, and manufacturing process that meets food safety standards. It is not only suitable for large-scale production but also can meet the needs of high-quality customisation. It is ideal equipment in the field of chocolate making. The following are the main markets targeted by this equipment:

Unique Technical Advantages of the Gondor Wheel Tempering Machine

The Gondor chocolate tempering wheel stands out among chocolate-making equipment with its exquisite manufacturing process and advanced technical features. Whether it is performance, design, or user experience, it shows unique advantages, can meet diverse production needs, and brings users an efficient and high-quality production experience. The following are the unique technical advantages of this equipment:

Chocolate Tempering Wheel – The Perfect Combination of Quality and Efficiency

This chocolate tempering wheel is specially designed for candy and food processing. It adopts a stainless steel body and a precise temperature control system to ensure uniform tempering and fine coating of chocolate. Its automatic stirring and vibration function can effectively improve the surface gloss and demoulding effect, and it is easy to operate and adapt to diversified production requirements. If it is necessary to build a complete production line, it can be used with a chocolate ball mill for fine grinding of raw materials, or combined with a chocolate enrobing machine to realise continuous coating processing. Welcome to contact us for a customised solution.