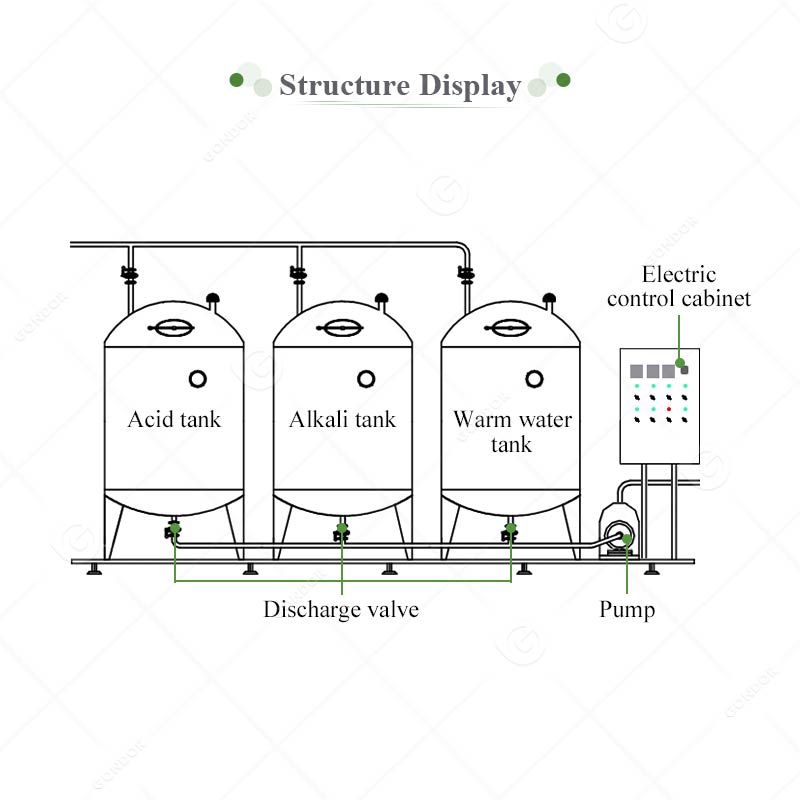

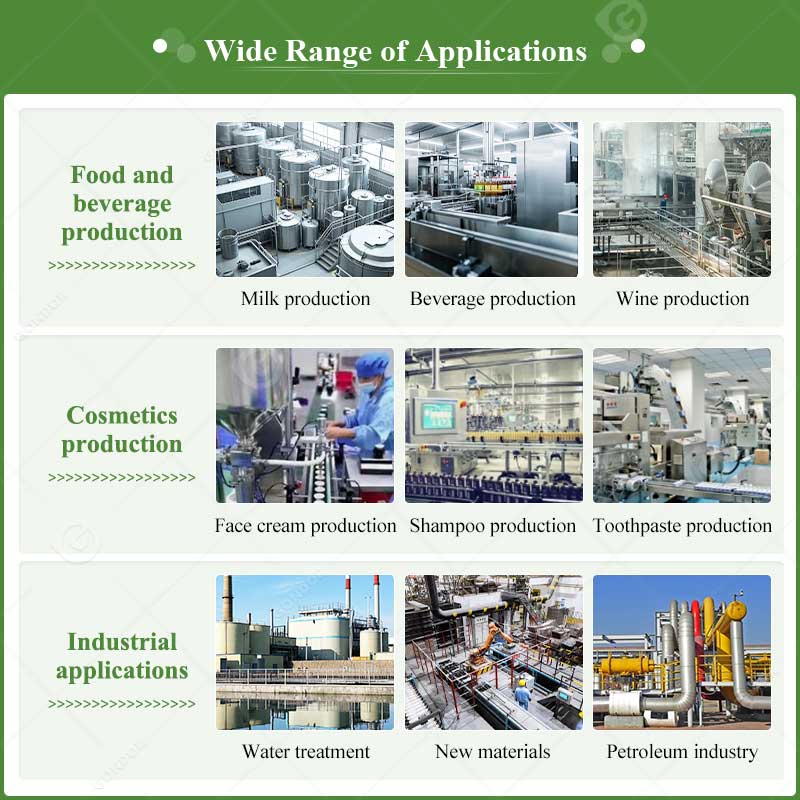

In modern food and beverage and biopharmaceutical industries, cleanliness is a compliance requirement and the key to ensuring product quality. Therefore, our CIP cleaning system has high-efficiency cleaning, intelligent control, and hygiene standards, and it is an ideal choice to realize intelligent cleaning and improve efficiency, and increase production. The CIP system does not need to disassemble the equipment. Still, it completely removes residues and microorganisms through the three-step cleaning process of acid water, alkaline water, and clean water to ensure the cleanliness and pollution-free inside the equipment. In addition, the system is widely used in dairy products, beverages, brewing, biopharmaceuticals, and other industries and fully meets the high-standard cleaning and automation requirements.

|

Model |

Voltage | Power | Flow | Size(mm) | Material |

| GD-CIPC-200 | 380V | 27KW | 3t/h | 2400*800*1500 | SUS304 |

|

GD-CIPC-300 |

380V | 36KW | 5t/h | 2800*1000*1600 | SUS304 |

| GD-CIPC-500 | 380V | 45KW | 10t/h | 3300*1000*2000 | SUS304 |

Applicable Industries of Clean in Place System

Core Advantages of Clean in Place Equipment

Open a Clean New Future

With the improvement of the quality and efficiency requirements of the manufacturing industry, the CIP cleaning system is becoming an important tool for all industries to move towards intelligent cleaning management. It is not only efficient and clean, but it also can ensure food safety and enhance brand value. If you are looking for an automatic, intelligent, and international cleaning equipment, the CIP system will be the ideal choice. Contact Gondor Machinery immediately to get the exclusive solution and jointly create an efficient, hygienic, and internationally competitive production environment!