Commercial vacuum meat tumbler marinator , also known as the vacuum pickling machine, is primarily used for processing a wide range of meats, including beef, lamb, chicken, duck, goose, pork, and fish. Additionally, it is suitable for seasoning and pickling various vegetables and fruits. With its stainless steel body, stable operation, spacious tumbling capacity, and ease of use, this machine offers multiple advantages. Through rolling, stirring, and massaging, the tumbling machine enables even absorption of the pickling liquid, which ensures excellent water retention and bonding strength in the meat, thereby enhancing both its elasticity and taste. Furthermore, operating under a vacuum helps to maintain the food’s freshness. The fully automated control system further enhances efficiency, allowing users to set parameters such as tumbling time, interval duration, and forward or reverse rotation to accommodate diverse processing needs.

| Model | Capacity(kg/tank) | Power(kw) | Weight(kg) | Machine Size (mm) |

| GR-30 | 15 | 0.75 | 70 | 850*360*780 |

| GR-50 | 25 | 0.95 | 100 | 906*500*808 |

| GR-100 | 50 | 1.3 | 150 | 1060*600*980 |

| GR-200 | 70 | 2.25 | 240 | 1400*800*1280 |

| GR-300 | 100 | 2.25 | 260 | 1410*1000*1450 |

| GR-500 | 240 | 2.25 | 300 | 1500*1020*1640 |

| GR-600 | 225-300 | 2.25 | 350 | 1560*1020*1640 |

| GR-800 | 300-400 | 2.95 | 460 | 1800*1200*1600 |

| GR-1600 | 600-800 | 3.75 | 975 | 2150*1330*2000 |

| GR-2000 | 750-1000 | 3.75 | 1090 | 2200*1440*2010 |

| GR-2400 | 1200 | 5 | 1300 | 2400*1500*2100 |

Wide Range of Market Applications of Gondor Vacuum Meat Tumbler

Significant Competitive Advantages of Gondor Commercial Vacuum Meat Tumbler

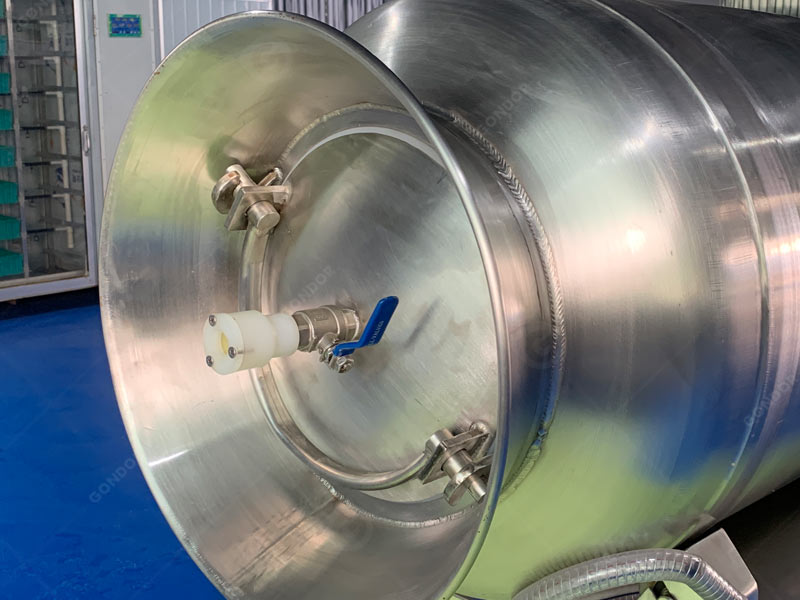

Stainless steel material is used, which is durable, anti-corrosive and anti-rust, ensuring the hygiene of food processing and the long-term use of equipment.

Well-designed, stable operation, can work for a long time under high load, and meet the needs of large processing plants.

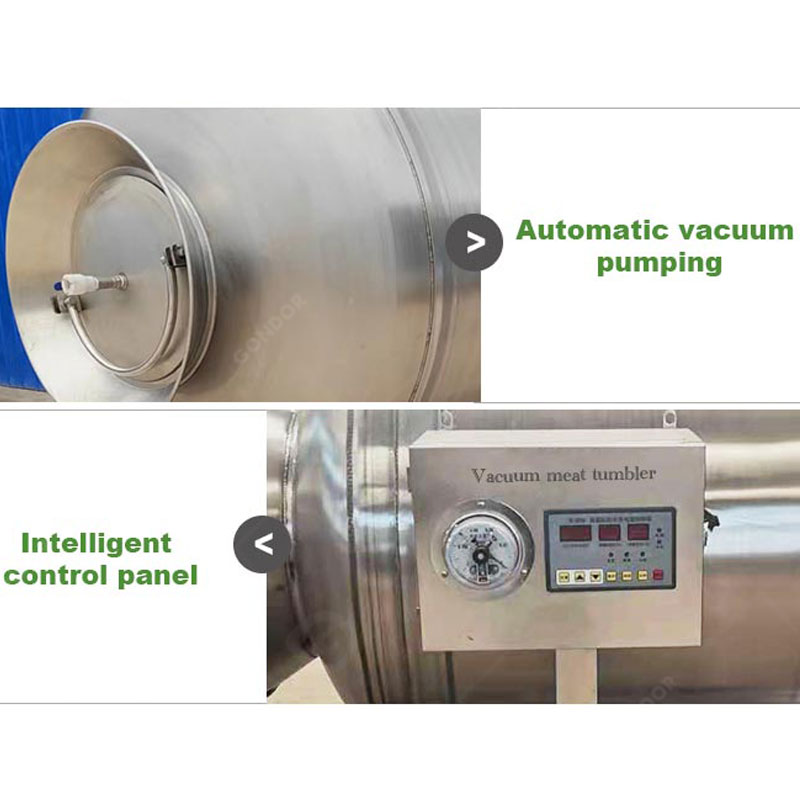

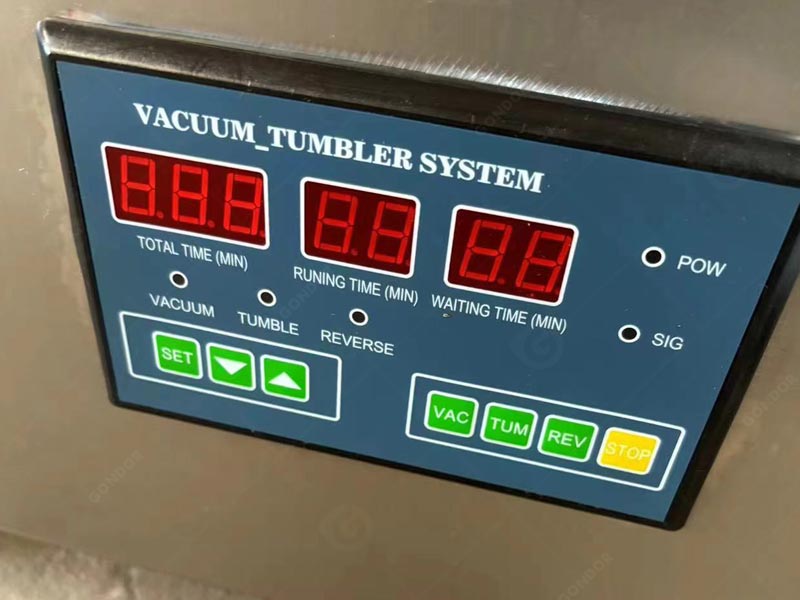

Equipped with a waterproof computer control system, it can automatically set the rolling and kneading mode, which is simple to operate and reduces labor costs.

The rolling and kneading space is large, which can handle a large amount of food at one time, suitable for batch production and improve processing efficiency.

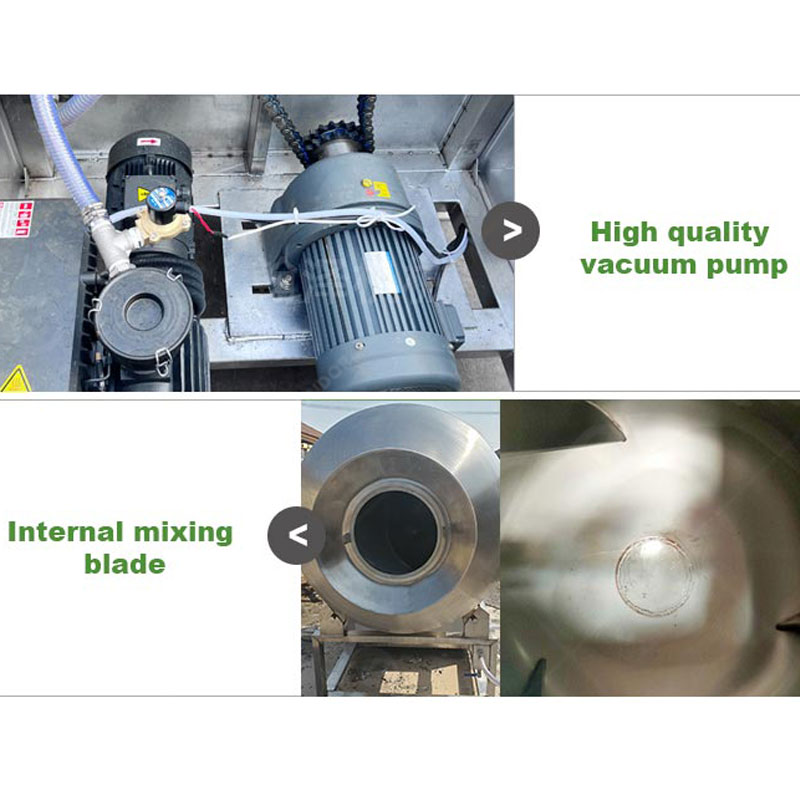

The arc design of the paddle blade makes the marinade evenly distributed, protects the appearance of the food, and improves the tenderness and water retention of the finished product.

Supports multiple modes such as frequency conversion, reversal, and discharging, and can adjust the rolling and kneading speed and mode according to different products.

Equipped with power failure memory function, the rolling and kneading process is restored after an unexpected power failure to ensure uninterrupted production.

Tumbling and kneading in a vacuum environment can effectively retain the moisture and nutrition of the ingredients, ensuring that the meat is tender and has a good taste.

Efficient and High-Quality Vacuum Roller – The Best Choice for Meat Processing

If you’re looking for equipment to enhance the quality of your meat, vegetable, or fruit processing, our commercial vacuum meat tumbler marinators are the ideal solution! Crafted from high-quality stainless steel, these machines feature intelligent controls and a power-off memory function, ensuring that the pickling liquid is thoroughly absorbed within a vacuum environment. This significantly boosts water retention, elasticity, and flavor of the product. Furthermore, they are perfect for a variety of applications, including ham, sausage, and quick-frozen foods, helping increase production capacity while reducing costs. We invite you to send an email or inquiry now to learn more about our latest models and special pricing. We’re here to provide you with comprehensive product solutions and support!