Efficient and Energy-Saving Continuous Mesh Conveyor Belt Dryer

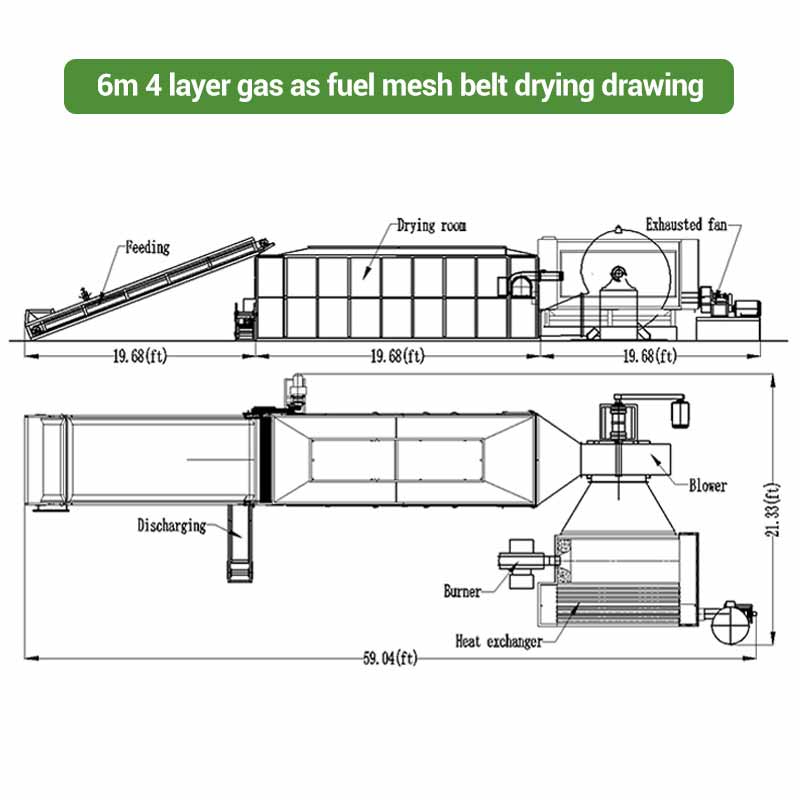

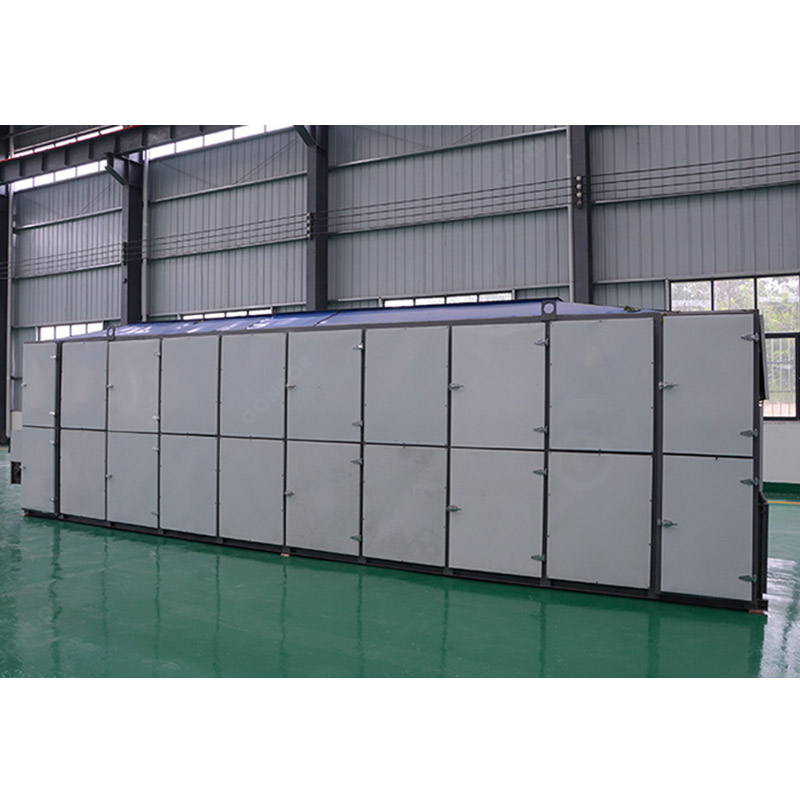

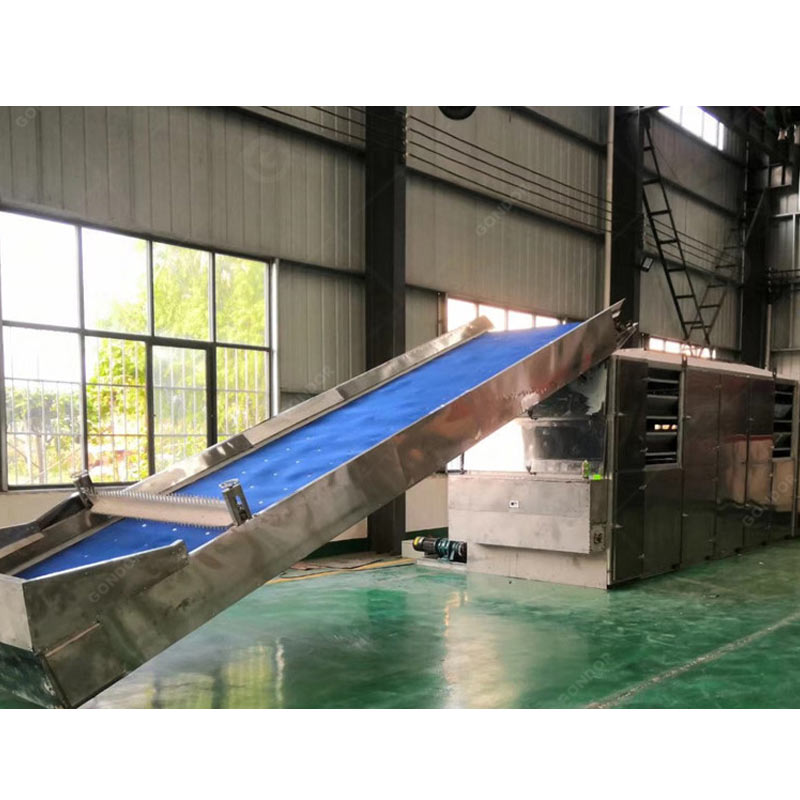

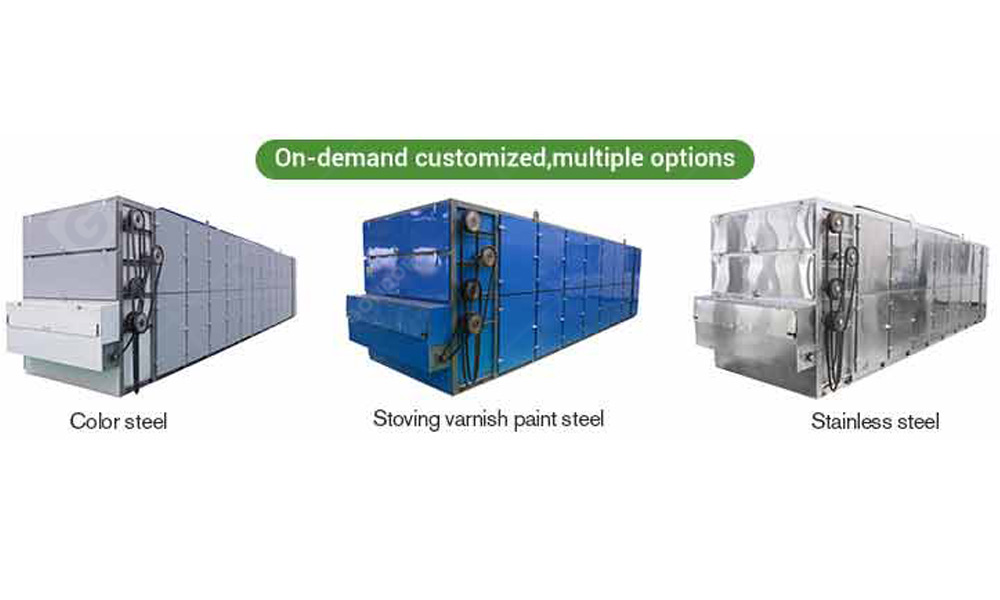

Continuous mesh conveyor belt dryer is an efficient, energy-saving drying solution that uses hot air as the drying medium. In this system, material is evenly spread and continuously conveyed through multiple layers of stainless steel mesh belts. As the hot air penetrates the material from the bottom to the top layer, rapid and thorough drying is achieved. Meanwhile, moisture is discharged from the top, and the dried product is transported out via the discharge conveyor. The equipment supports various heat sources, including electricity, gas, and diesel, allowing users to select the most convenient and economical option. Furthermore, heat is evenly distributed to ensure a pollution-free drying process, and the temperature, humidity, and air volume can all be intelligently adjusted. Additionally, its high-strength chain is wear-resistant, while the food-grade stainless steel screen ensures safety and durability. This dryer is particularly suitable for small-scale processing of vegetables and fruits, making it an ideal choice for small and medium-sized production.

| Model | GD-8 | GD-9 | GD-10 | GD-12 |

| Layer | 4 layers, 5 layers, 6 layers | |||

| Material thickness | 10-70mm | |||

| Drying temperature | 40~120°C | |||

| Humidity reduce | 75% to 8% (Customized) | |||

| Drying time | 0.5-5 hours | |||

| Power of main engine | 1.5kw | 1.5kw | 2.2kw | 3kw |

| Hot air draft fan | 15kw | 15kw | 22kw | 22kw |

| Conveyor discharge | B500(0.12kw) | B500(0.12kw) | B500(0.12kw) | B500(0.12kw) |

| Note:The above parameters are for reference, we customize the machine according to customers’ requirements and provide the best solutions. | ||||

Mainly Applicable Markets for Gondor Mesh Belt Dryer

Applicable to drying agricultural products such as vegetables, fruits, spices and scented tea, increasing the added value of agricultural products and extending the shelf life.

Widely used in drying foods such as meat and nuts to ensure food hygiene and drying efficiency.

Suitable for small batch production, providing convenient drying solutions for farmers and family processing plants.

Especially suitable for enterprises with daily processing capacity below 5 tons, meeting the needs of small and medium-sized production and meeting environmental protection requirements.

Due to its high efficiency, energy saving and green environmental protection characteristics, it meets the requirements of environmental protection policies, and some regions can also obtain machine purchase subsidies.

Supports a variety of heat source options, such as biomass and new energy, in line with the development trend of new energy.

Significant Competitive Advantages of Gondor Group Continuous Belt Dryer

High Efficiency and Energy Saving – Gondor Conveyor Belt Dryer

Gondor continuous mesh conveyor belt dryer provides you with efficient, continuous and energy-saving drying solutions. The equipment adopts multi-layer stainless steel mesh belt transmission, and the circulating hot air penetrates the material layer evenly to ensure the rapid and thorough drying effect. It supports many kinds of heat sources such as electric energy, gas and diesel oil, and is equipped with intelligent temperature control and humidity adjustment system to realize fully automatic operation and meet the requirements of environmental protection and clean production. It is especially suitable for large-scale drying processing of vegetables, fruits, Chinese herbal medicines and meat products, which can effectively improve productivity and reduce energy consumption.

If you have higher requirements for the retention of active ingredients and forms of materials, you can further cooperate with a vacuum freeze drying machine to form a complete drying production line from conventional drying to high-end freeze-drying, covering a wider range of product needs and application scenarios. Welcome to contact us immediately to get customized drying scheme and professional selection support, and start a new stage of efficient and intelligent drying production!