One-Stop Solution for Premium Grain Processing

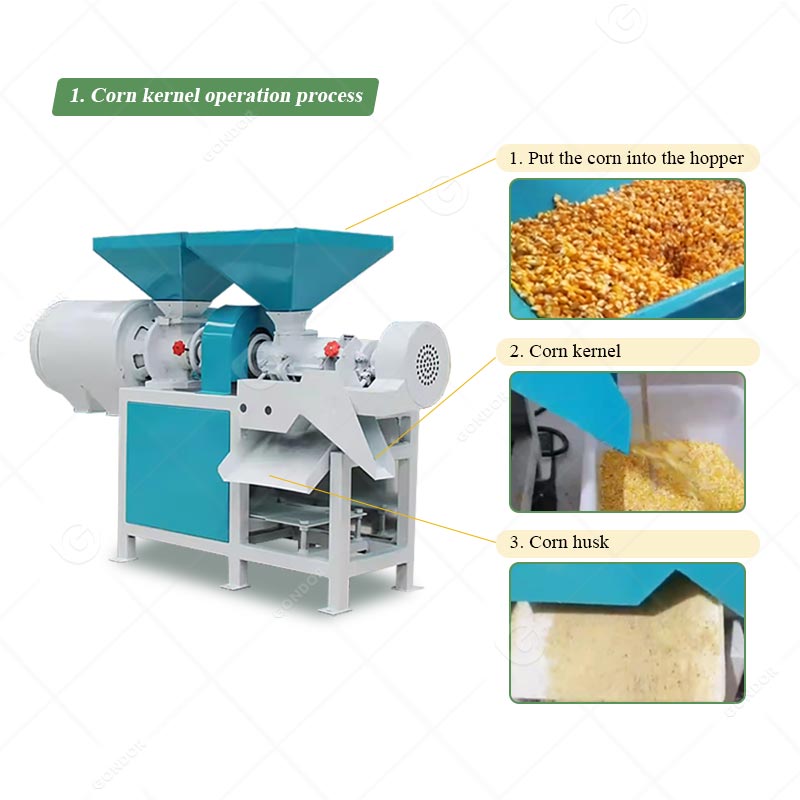

Corn grits grind milling machine is a kind of equipment specially used for peeling and grinding corn, wheat, barley and other grains, rice and sorghum. Moreover, Gondor’s equipment has added new ventilation and dust removal system, stepless crushing system, current display system and automatic air outlet adjustment system. In addition, the machine also adopts wet dust removal to refine corn kernels, corn flour and other varieties. It is suitable for the peeling, crushing and grinding needs of small and medium-sized grain processing plants such as wheat, rice, corn and sorghum, and the processed finished products can be directly put into the market for sale.

| Model | Output(kg/h) | Power (kw) |

Spindle speed (r/min) |

Weight (kg) |

Machine size (mm) |

|

| GD-5B | corn peeling | Corn Grits | 11 | 1042 | 350 | 2140*1130*1200 |

| 800 | 1000 | |||||

| GD-3B | corn peeling | Corn Grits | 7.5 | 860 | 300 | 2200*500*1200 |

| 300 | 500 | |||||

Industry Fields Served by Corn Grits Milling Machine

- Adjust the appropriate particle size of corn grits according to demand to produce corn noodles, corn dumpling wrappers, etc., to meet the requirements of noodle making.Pasta Processing Enterprises

- Some liquors use corn as one of the raw materials, and corn can be processed into a particle size suitable for brewing, which is conducive to improving fermentation efficiency and wine quality.Liquor Brewing Enterprises

- Some specialty beers also add a small amount of corn grits to increase flavor. Corn grits machine can provide high-quality corn grits raw materials for beer brewing enterprises.Beer Brewing Enterprises

- Corn is one of the main raw materials for livestock and poultry feed. Grits of corn with different particle sizes can meet the feeding needs of different animals.Livestock and Poultry Feed Production Enterprises

- Adding an appropriate amount of corn grits to aquatic feed can increase the energy content and palatability of the feed, which helps to improve the utilization rate of the feed.Aquatic Feed Enterprises

- Process the corn they grow into corn grits for home consumption or sell to nearby residents. This not only increases the added value of corn, but also increases farmers’ income.Individual Farmers

- They can produce corn grits and other products for the local market. The machine is easy to operate and low cost, suitable for small workshops.Rural small workshops

Powerful Functional Advantages of Corn Grits Grind Machine

Durable and Reliable

The grits making and grading screening rotors have been subjected to dynamic balancing tests and have high durability and reliability.

Efficient Processing

600-800kg of raw materials can be processed per hour, with high efficiency and large output.

Uniform Particles

Corn grits have uniform particle size, no magazines, no micro skins, ensuring stable product quality.

Easy to Operate

The equipment is easy to operate and can be operated in a mobile or fixed manner, which reduces the difficulty of manual operation.

Easy to Clean

Reasonable structural design, easy to clean and maintain, ensuring food hygiene and safety.

Strong Adjustability

By adjusting the gear, the particle size can be controlled to meet diverse market demands.

Wide Applicability

It is suitable for corn of different varieties and qualities and has a wide range of applicability.

Core Technology Upgrades

Production Line Integration Solutions

To establish a complete corn processing line from raw grain to finished products, the corn gritter can be integrated with the following equipment to form a highly efficient, coordinated operational system:

Pre-processing Equipment Integration:

- Sweet Corn Threshing Machine: Efficiently de-cobs harvested corn cobs, supplying clean, intact corn kernels to the gritter for front-end automation.

- Grain Cleaner: Removes stones, dust, metal contaminants, and other impurities from corn, effectively protecting downstream equipment and enhancing finished product purity.

- Mobile Grain Dryer: Rapidly reduces high-moisture corn to the standard moisture content required for safe storage and processing, ensuring stable grit production and consistent product quality.

Post-Processing and Packaging Integration:

- Automatic Packaging Machine: Connects to the gritter’s outlet for automated weighing, bagging, and sealing of finished corn grits, enhancing packaging efficiency and hygiene standards.

- Screw Conveyor System: Links individual machines to enable automated material flow between cleaning, drying, gritting, and packaging stages.

Frequently Asked Questions

Gondor Corn Grits Grind Milling Machine – Open the Road to Wealth

Our corn grits grind milling machine has excellent performance and can efficiently process corn into high-quality corn grits. Whether it is a food processing company, a catering store or a rural cooperative, it can play a huge role. Gondor’s quality is guaranteed and the after-sales service is considerate. Order now, let us use the corn grits machine to open up the market, create wealth, and share the joy of success! Act quickly!