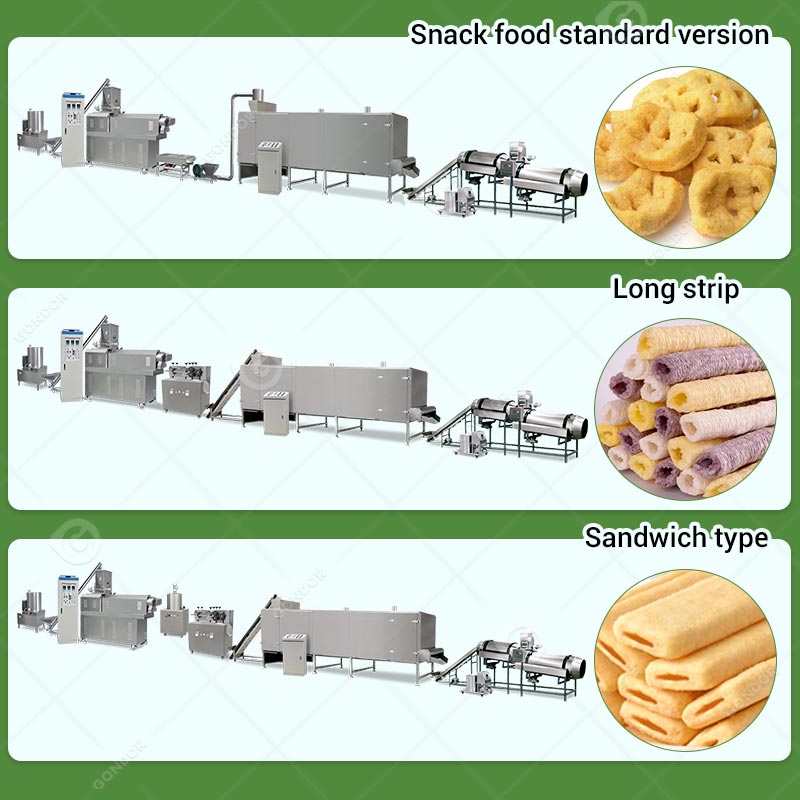

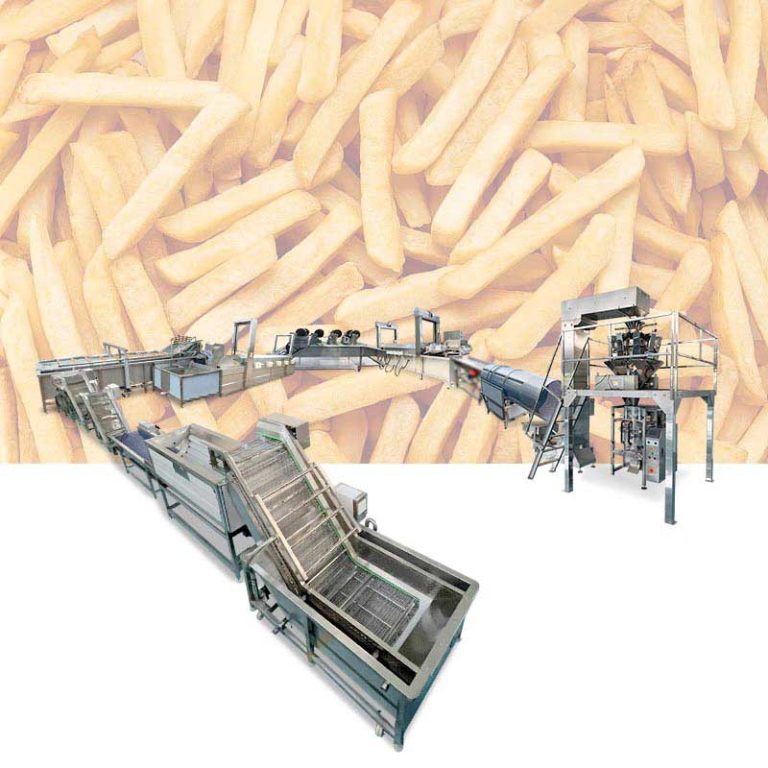

The corn puff production line is a set of food processing systems integrating automation, high efficiency, and multifunction, which is specially designed for the production of various puffed snack foods. The production line adopts advanced twin-screw co-extrusion technology, which can extrude two materials with different textures and flavors at the same time to produce a variety of puffed foods such as sandwich rice fruit, rice crisp, shell shape, spiral shape, and square tube shape. It is suitable for corn, rice, wheat flour, potato starch, pea flour, and other cereal and potato raw materials, and the diversified development of food appearance and flavor can be easily realized by changing the mold and seasoning system.

| Name |

Voltage |

Power |

Yield |

Material |

Size |

| Powder mixer |

380V |

7.5kw |

5-20 min/once |

201SUS |

1470*830*1650mm |

| Screw feeder |

1.1kw |

100-300 kg/h |

304SUS |

2500*600*2400mm |

| Puffing extruder |

46.62kw |

100-200 kg/h |

201SUS |

2500*780*1925mm |

| Vibrating screen |

0.18kw |

150-200 kg/h |

304SUS |

1500*750*850mm |

| Wind conveyor |

2.2kw |

100-300 kg/h |

304SUS |

2000*600*2300mm |

| Circulation dryer |

69.8kw |

150-200 kg/h |

304SUS |

8200*1500*2000mm |

| Cooling conveyor |

0.87kw |

/ |

304SUS |

5000*600*1400mm |

Application Market of Puff Snacks Processing Line

The puff snacks processing line can flexibly adjust the formula and mold. It can quickly respond to the market trend and develop new flavors such as tomato flavor, barbecue flavor and spicy flavor to meet the taste needs of consumers in different regions of the world. The equipment can be widely used in the following markets and fields:

Snack Food IndustryChildren's Food MarketHealthy Cereal SnacksAviation, Cinemas and Vending ChannelsOEM Foundry

This equipment can produce various puffed snack foods with crisp taste and various shapes on a large scale and meet the diversified demands of the mass market for snacks.

By changing the mold and seasoning formula, children’s exclusive puffed snacks with rich colors, interesting shapes, and reasonable nutrition were produced.

Coarse grains, miscellaneous grains, and other healthy raw materials can be used to make low-fat and high-fiber puffed cereal snacks, which is in line with the modern consumer health concept.

The puffed food produced by the equipment has convenient packaging and long shelf life, and is suitable for instant consumption scenes such as aviation, cinemas and vending machines.

The production line supports rapid mold changing and formula adjustment, which helps OEM enterprises to flexibly respond to multi-brand orders and improve production efficiency and market response speed.

Outstanding Equipment Features of Snack Food Production Line

Inverter Speed Control

The main engine is equipped with a high-efficiency frequency converter to realize accurate speed control and improve production stability and energy-saving efficiency.

Self-cleaning Screw System

The optimized twin-screw structure has self-cleaning ability, reduces downtime and is convenient for refueling and maintenance.

Forced Lubrication System

Ensure that the spindle and screw still run smoothly at high speed, and greatly extend the service life of the equipment.

Wide Raw Material Compatibility

Support a variety of cereal and potato powder raw materials, and flexibly meet the needs of raw material supply and cost control.

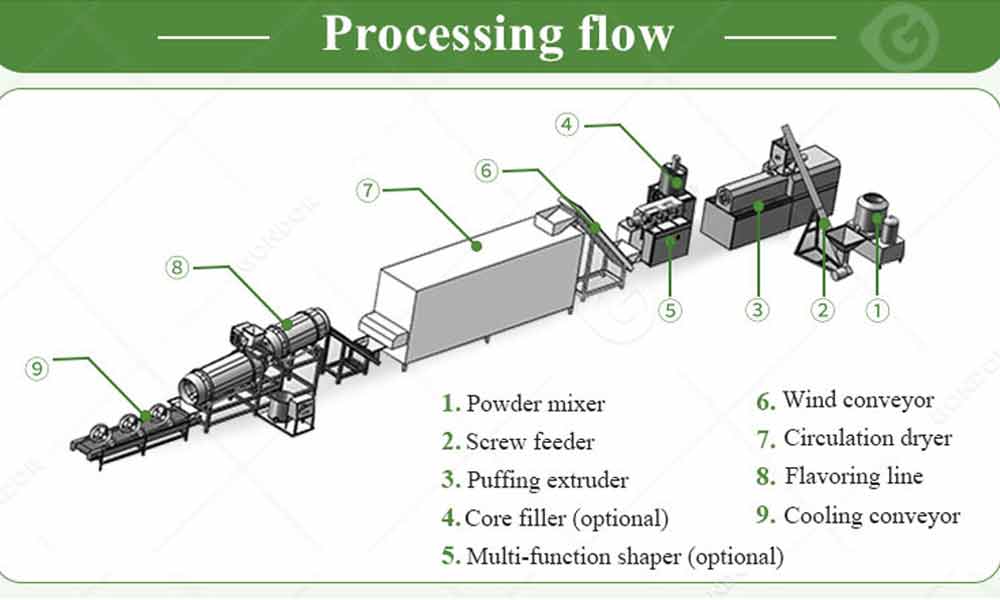

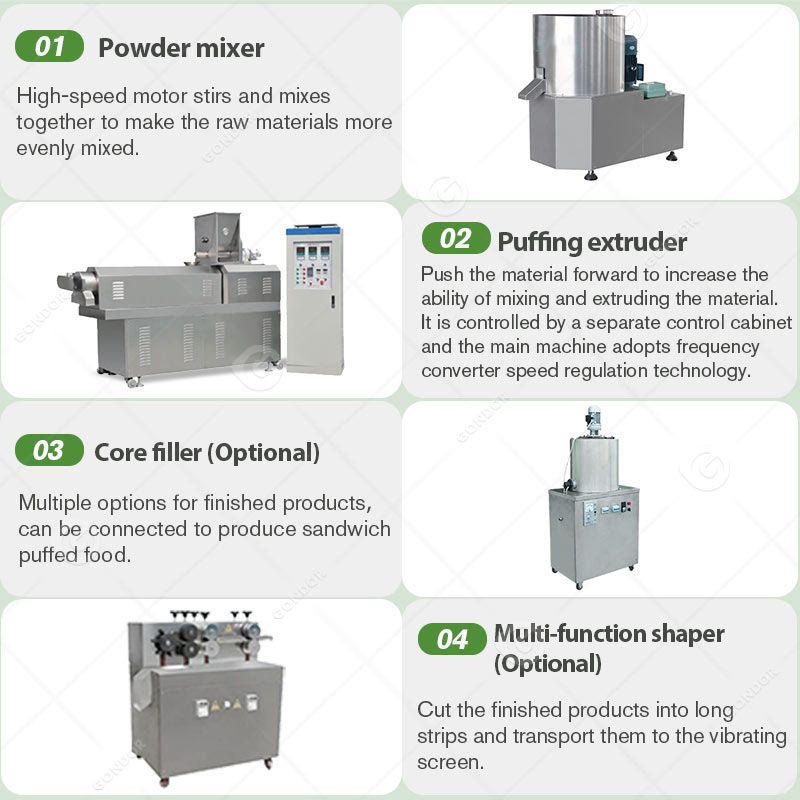

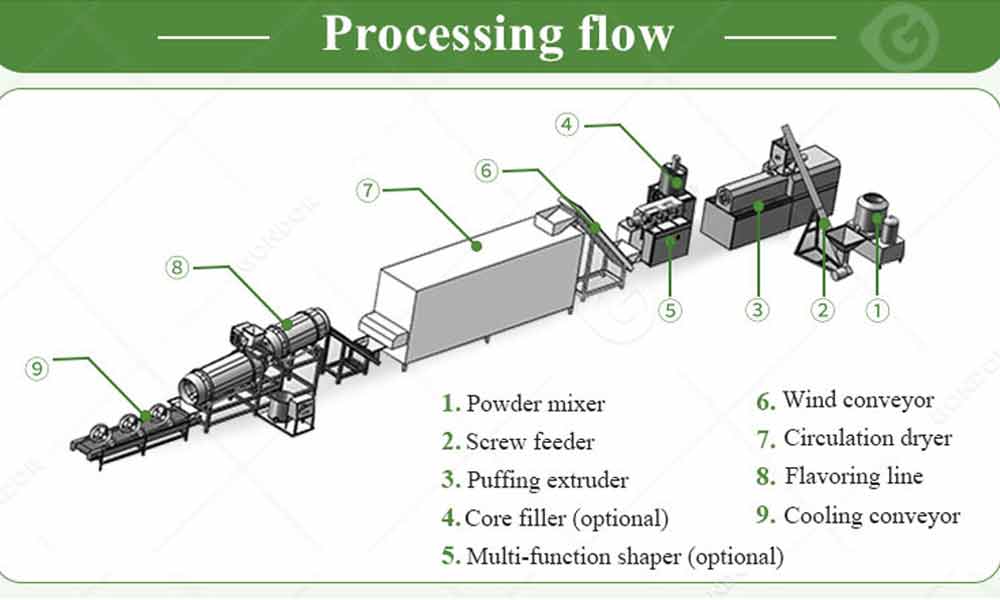

Modular Design

The equipment consists of powder mixer, screw feeder, puffing extruder, sandwich machine, shaping and cutting machine, vibrating screen, wind conveyor, circulating dryer, seasoning drum, cooling conveyor, etc., which can be flexibly configured according to production capacity and product demand.

Food-grade Material Contact

All parts in contact with materials are made of stainless steel or food-grade materials, which meet international food safety standards.

Related Machines

Our corn puff production line is excellent, and we can flexibly adjust the formula and mold. At the same time, we also provide related packaging machines:

Let us create a highly automated, flexible, and efficient puffed food solution for you. Feel free to contact us for customized quotations and technical solutions!