Gondor Disposable Bowl Making Machine

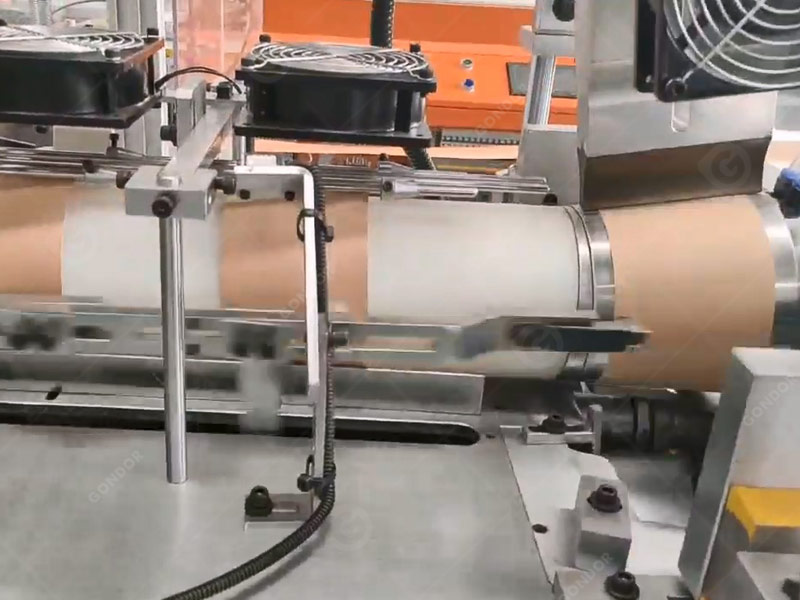

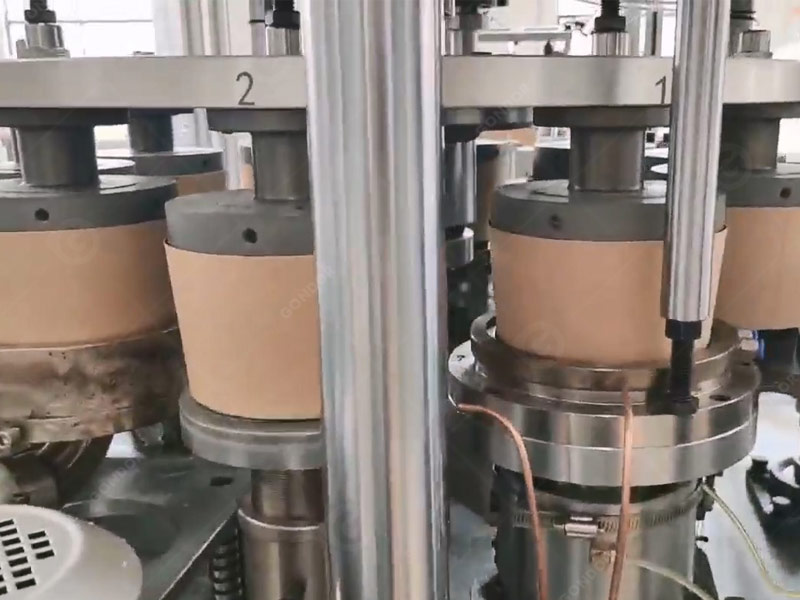

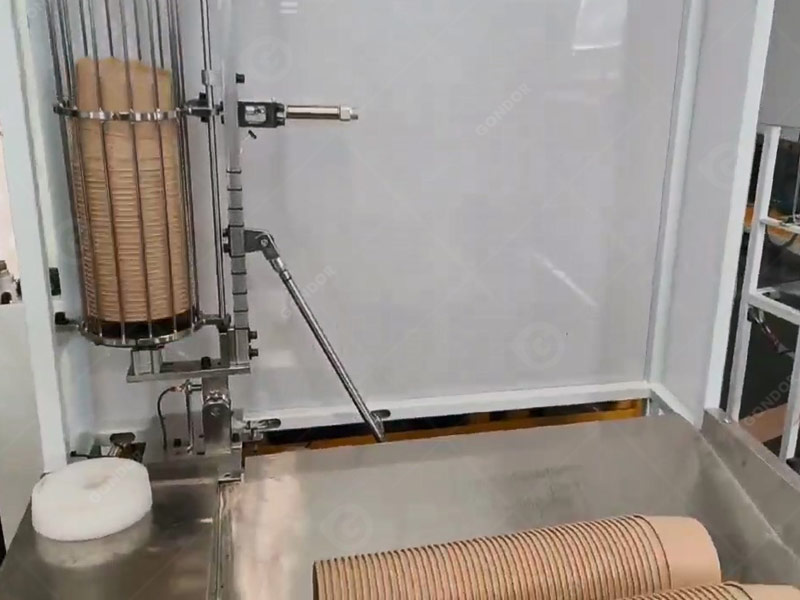

Disposable paper bowl making machine is a kind of equipment specially used for producing paper bowls. It is mainly composed of paper feeding mechanism, forming mechanism, heating device, sealing mechanism and control system. The working principle of the paper bowl machine is to feed the paper into the forming mechanism, and through the action of heating and mold, the paper is formed into the shape of a paper bowl, and then sealed. Moreover, Gondor paper bowl making machine has high efficiency and stable performance, and can also adjust parameters to produce paper bowls of different specifications and shapes. In addition, the equipment has a high degree of automation, simple operation, and wide application, which provides strong support for meeting the market demand for paper bowls.

| Name | Paper bowl making machine | |

| Model | GD-D800 | GD-T185 |

| Power | 12kw | 15kw |

| Max paper bowl size | 1400ml | 1500ml |

| Working Air Source | 0.6-0.8Mpa; 0.4m³/min | 0.5-0.8Mpa; 0.6m³/min |

| Paper Material Requirements | Single and double laminated paper | |

| Output | 60-70 pcs/min | 40-60pcs/min |

| Paper weight | 200-330g/m²;±20g/m² | 240-340g/m²;±20g/m² |

| Bowl size | Bottom:80-125mm,Top:100-148mm; Height: 125mm. |

Bottom:125-165mm,Top:150-185mm; Height: 45-80mm. |

| Size | 2350*1320*1900mm | 2150*1320*1900mm |

| Weight | 3000kg | 2800kg |

| Cup Side Sealing | Ultrasonic | |

| Bottom Knurling | HOT AIR SYETEM | |

Application Market Scope of Gondor Paper Bowl Making Machine

Provide customized paper bowl production services for convenience food companies to meet the different needs of enterprises, and also ensure the quality of convenience foods during transportation and storage.

Frozen foods such as ice cream, quick-frozen dumplings, etc. can also be packaged in paper bowls. The paper bowls produced by the paper bowl machine can withstand low temperature environments and will not break or deform.

The exhibition provides food for exhibitors and visitors. Paper bowls are convenient and hygienic and can meet the needs of the exhibition. Customized paper bowls can be printed with the logo and information of the exhibition to play a promotional role.

It can be used to hold rice, noodles, snacks and other foods to meet the large demand of fast food restaurants. The brand logo and promotional information of the fast food restaurant can also be printed to promote it.

Paper bowls are usually used to hold wontons, dumplings, etc., which are convenient and hygienic, suitable for the business characteristics of snack bars, and can also meet the packaging needs of different snacks.

Use paper bowls to package food to ensure the safety and hygiene of food during delivery. Moreover, customized paper bowls can increase the brand recognition of takeaway merchants and attract more customers.

In outdoor activities such as picnics and camping, environmentally friendly paper bowls are not only light and easy to carry, suitable for outdoor activities, but also can reduce pollution to the environment.

Significant Competitive Advantages of Gondor Machinery Disposable Bowl Making Machine

- The degree of automation is extremely high. Automatic paper feeding is accurate, heat sealing is tight, and each link cooperates seamlessly to efficiently complete the production of paper cups.Efficient Integration

- >It occupies a small area and is extremely simple to operate. One person can do it. Low investment and low risk are practical choices to reduce costs for enterprises.Convenient and Practical

- Replace molds to produce products of different shapes and specifications to meet diverse needs and provide possibilities for enterprises to expand their business.Flexible and Changeable

- PLC screen supports multiple languages, can store multiple sets of parameters, and the manual button makes operation more convenient and improves work efficiency.Intelligent and Easy to Use

- Cup body adopts ultrasonic heat sealing, which does not damage the printing surface and is highly efficient. Improve the appearance of the product and enhance market competitiveness.High-Quality Bonding

- The bottom of the paper cup is rolled after bonding, which is fine and beautiful. Improve product quality, increase product recognition, and attract consumers’ attentionFine Knurling

- There is an automatic lubrication system to save time and effort. Improve efficiency, extend machine life, reduce maintenance costs, and ensure production continuity.Automatic Lubrication

- Equipment external guardrails put safety first. Protect personal safety, reduce accident risks, and provide a reliable and safe environment for production.Safety Assurance

Smart Production Line Integration Solutions

To meet the demands of large-scale and automated production, we offer comprehensive production line integration solutions that seamlessly interface with the following equipment:

- Paper Cup Machine: Shares raw materials and control systems, enabling flexible production switching to boost equipment utilization.

- Pillow Packaging Machine: Direct integration achieves stacking, film wrapping, and sealing of paper bowls.

- Product Traceability System: Sprays QR codes on the bottom of each paper bowl, enabling end-to-end quality traceability from production to sales.

Gondor Disposable Paper Bowl Making Machine – Opening a New Journey of Efficient Production

Our disposable paper bowl making machine brings a new revolution to your production. It has excellent performance, easy operation, and can quickly and efficiently produce high-quality paper bowls of various specifications. Whether it is the catering industry, food processing or takeaway field, it can be perfectly adapted. And the precise molding process ensures the stability and reliability of the quality of the paper bowl. Choosing Gondor paper bowl machine means choosing efficiency and quality. Let us work together to improve production efficiency, reduce costs, and open up a broader market. Come and order it and start your road to success!