Gondor Dry Ice Cleaning Machines

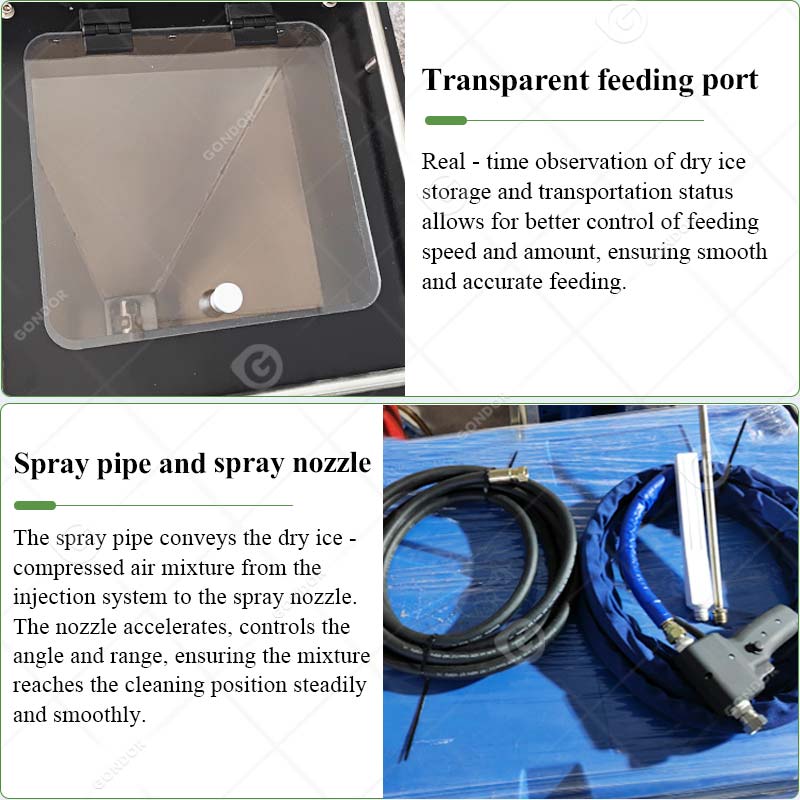

A dry ice cleaning machine is an environmental protection equipment that uses dry ice particles as a cleaning medium. Dry ice is sprayed onto the surface at high speed by compressed air, and impurities such as dirt, oil stains, and colloid are quickly stripped by using the impact force and cold shrinkage effect generated by the instantaneous sublimation of dry ice when it is heated. The cleaning process is waterless, corrosion-free, and residue-free and does not damage the surface of objects.

Compared with the traditional cleaning method, it is faster and more applicable, especially suitable for industrial environments with high cleaning requirements, and is an ideal choice for green production.

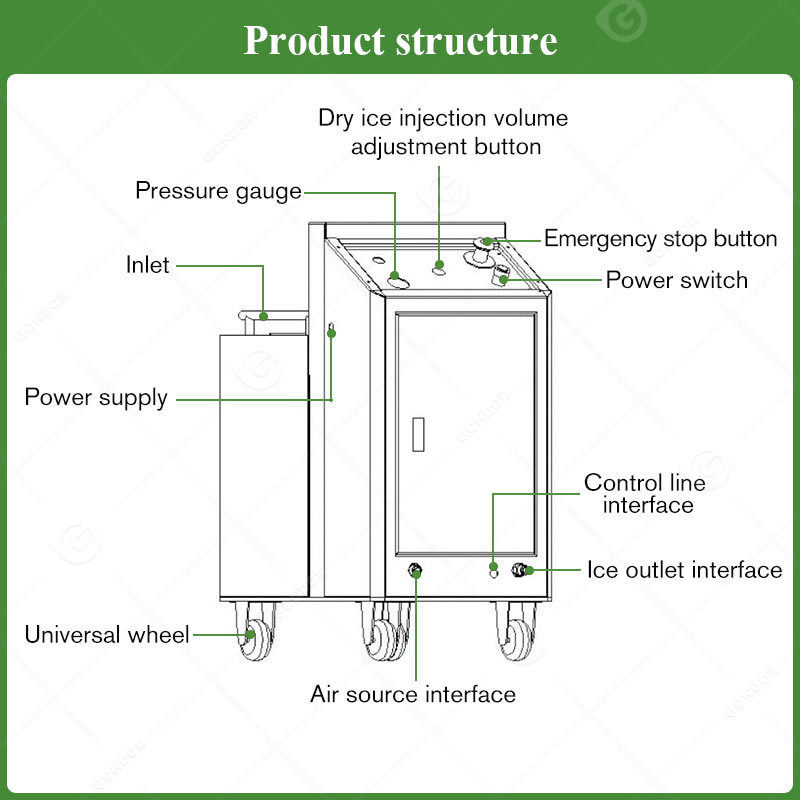

Dry Ice Cleaning Machine Specifications

| Model | GD-DIBM01 | GD-DIBM02 | GD-DIBM03 |

| Dry ice capacity | 30L | 16L | 5L |

| Size | 600*400*700mm | 700*500*980mm | 600*380*698mm |

| Weight | 68KG | 110KG | 80KG |

| Adjustable dry ice dosage | 0-2kg/min | 0-3kg/min | 0-1.8kg/min |

| Air supply pressure range | 5-10bar | 5-10bar | 2.5-10bar |

| Compressed air flow requirements | 2-3m³ /min | 2-4m³ /min | 0.5-1.5m³ /min |

| Voltage | 220-240V | 240V | 240V |

| Power | 750W | 1000W | 850W |

Widely Applicable Industries of the Dry Ice Blasting Machine

Dry ice blasting machine is widely used in many fields and adapts to all kinds of complex scenes, which can be called “one machine for multiple purposes”:

Excellent Performance of Ice Blasting Machine

Using the sublimation principle of dry ice, stubborn oil, colloid, and carbon stains can be quickly removed without any secondary pollution.

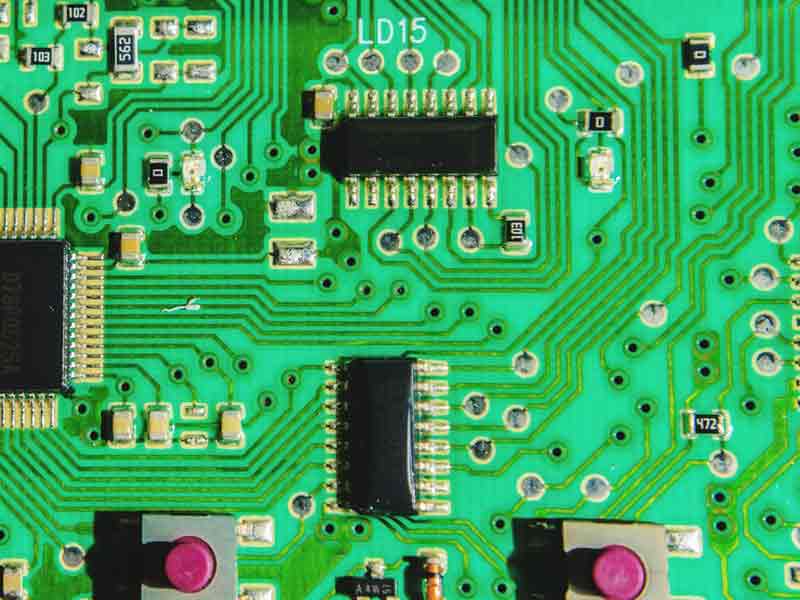

No wear, no corrosion, no surface damage to metal, plastic, ceramics, electronic components, and other surfaces.

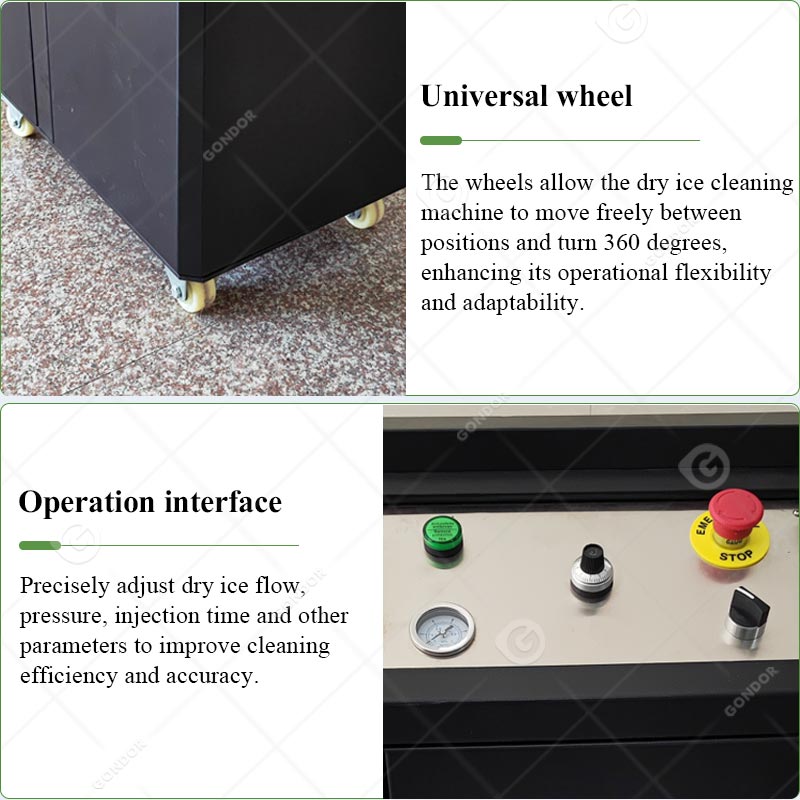

Equipped with universal wheels, it supports 360 free movement, flexibly adapts to various workplaces, and improves working efficiency.

CO₂ is non-toxic and harmless and does not produce waste water or waste liquid during cleaning, which conforms to environmental compliance and does not need additional chemical treatment.

Equipped with pa recise adjustment interface, dry ice flow, injection pressure, and time can be adjusted in real time, which is simple and easy to operate.

It can penetrate cracks and holes with complicated structures and is especially suitable for the precision cleaning of electronic and electrical components.

Efficient and Environmentally Friendly Cleaning Solution

If your enterprise needs to deal with surface cleaning with different materials or special structures, please know about our other cleaning equipment, such as:

- Dry Ice Pellet Making Machine

- High-pressure Water Jet Cleaner

We are committed to providing customers around the world with the most cutting-edge and reliable industrial cleaning solutions. For more information or a quotation, please contact us! Upgrade your cleaning method immediately, and choose the dry ice cleaning machine with high efficiency, environmental protection, and safety, which will make the equipment look brand-new and bring a breakthrough in productivity to the enterprise!

Q1: How does the dry ice cleaning machine work?

A: It works by using compressed air to spray dry ice particles at high speed onto the surface. It utilizes “instant cold contraction + impact peeling”, and during this process, the dry ice sublimates (changes from solid to gas), thus removing the dirt from the substrate.

Q2: What kinds of dirt can be cleaned?

A: Oil stains, carbon deposits, glue residues, ink, splashed coatings, rubber/plastic residues, release agents, food residues, etc. (The effectiveness depends on the substrate and the thickness of the dirt.)

Q3: Will it damage the surface of the workpiece?

A: Compared to sandblasting, this method is less “abrasive”, but still requires correct parameters. The particle size, air pressure, and nozzle type can be adjusted to suit aluminum parts, plastics, molds, precision components, etc.

Q4: Will there be secondary pollution after cleaning?

A: No. The dry ice will sublimate into CO₂ gas, leaving no water, chemical solvents or residue; only the dirt removed during the cleaning process needs to be dealt with on-site.

Q5: What are the requirements for the air compressor?

A: Stable, dry and clean compressed air is needed. Generally, it should have sufficient pressure and flow rate, and it is recommended to install a dryer/filter; we can recommend the configuration based on the working conditions.

Q6: Can the electrical cabinets and motors be cleaned online?

A: Dry ice cleaning is dry and non-conductive, and is commonly used for cleaning the surfaces of electrical equipment. However, it must be operated in accordance with the specifications (power off/ventilation/risk assessment), and the process should be formulated based on the actual working conditions.