Gondor’s edible oil refinery machine is designed for efficient processing and is suitable for over 20 types of oil crops, including olives, peanuts, sesame, soybeans, and more. The equipment is made from food-grade stainless steel, which is both corrosion-resistant and heat-resistant, meeting national food machinery standards. It integrates multiple functions, such as dephosphorization, dealkalization, dehydration, and decolorization, effectively removing impurities and harmful substances through both physical and chemical refining methods. Furthermore, it is suitable for a variety of applications, including oil mills and food processing plants. With low investment costs and high returns, this equipment is an ideal choice for global customers looking to refine crude oil.

Model | Processing capacity(kg/batch) | Motor power(kW) | Voltage(v) | External dimensions(mm) | Weight(kg) |

| GD-ORFM500 | 150 | 4.5 | 220/380 | 1740*680*1510 | 180 |

GD-ORFM750 | 300-600 | 9.5 | 220/380 | 2340*930*1700 | 300 |

| GD-ORFM750B | 450-900 | 15 | 380 | 3820*930*1700 | 550 |

GD-ORFM700 | 500-1000 | 52 | 380 | 4500*1080*2320 | 1200 |

GD-ORFM700B | 500-1000 | 8.2 | 380 | 3500*880*1800 | 1000 |

Demand Areas for Gondor Refinery Machine

Gondor’s oil refining equipment is widely used in the processing of various oil crops due to its efficient refining capacity and multifunctional design. Whether in food processing, catering industry, or in chemical, pharmaceutical and other industrial fields, this equipment can provide high-quality oil refining solutions. The following are the main demand areas for this equipment:

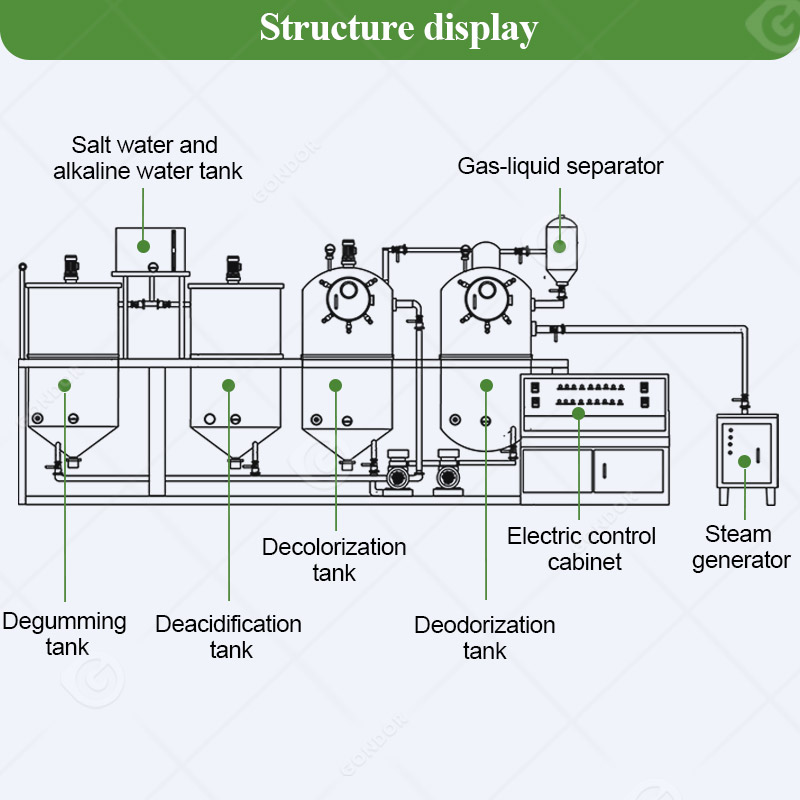

Unique Mechanical Characteristics of Gondor Cooking Oil Refinery Machine

Gondor’s oil refining equipment has demonstrated its unique advantages in the oil refining process with its advanced technical design and efficient performance. The equipment is not only suitable for the refining of a variety of oil crops, but also ensures the efficiency, stability and product quality of the refining process through a series of innovative mechanical characteristics.

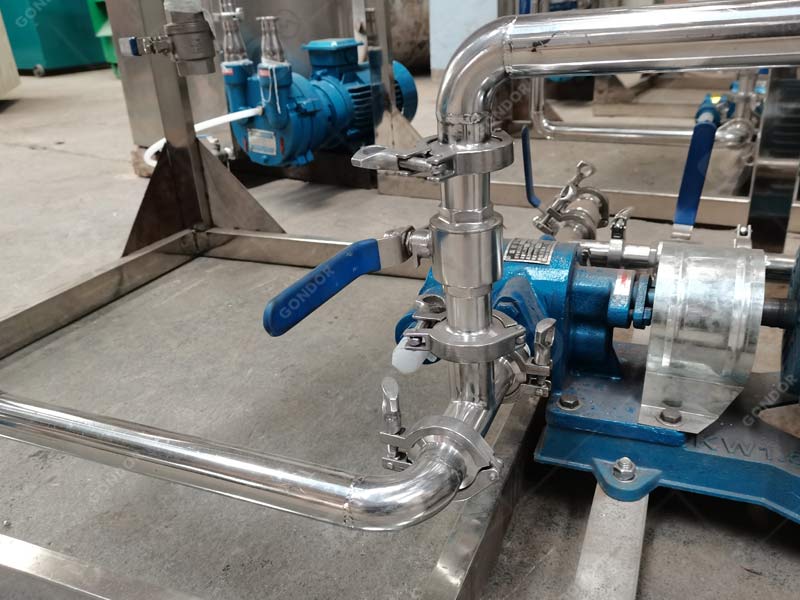

Adopting food grade stainless steel, it is corrosion-resistant and high temperature-resistant, meets national food machinery standards, and ensures that the oil is pollution-free.

Integrated dephosphorization, dealkalization, dehydration, decolorization and other multi-functions, flexible customization, improve equipment applicability, and remove oil impurities.

The automated electronic control system simplifies operation, intelligently monitors the refining process, and reduces human errors.

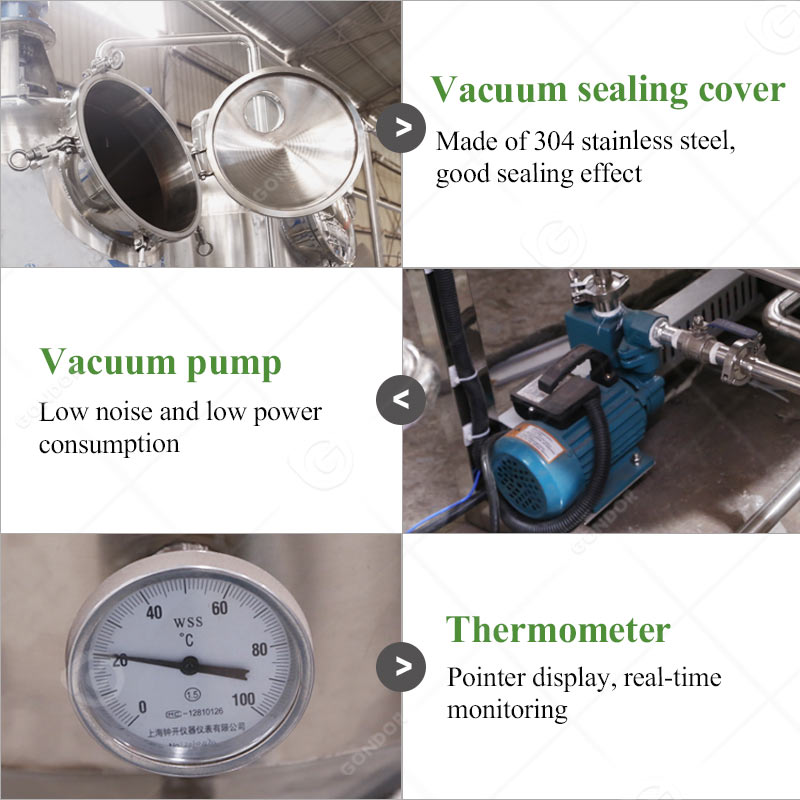

The efficient vacuum pump removes moisture and volatile impurities to ensure a quiet production environment.

304 stainless steel vacuum sealing cover prevents external pollution and ensures the purity of oil products.

Built-in water circulation system saves water resources, optimizes energy use, and reduces operating costs.

Quickly separates water and steam, improves refining efficiency, and reduces energy consumption.

Precise temperature control system monitors in real time to ensure the appropriate temperature in each link and improve oil quality.

The compact design saves space, and the modular structure facilitates installation, disassembly and maintenance, improving production efficiency.

Gondor Edible Oil Refinery Machine Improves Oil Quality and Reduces Costs

Gondor’s oil refining equipment is widely used in the refining of various oil crops such as olives, peanuts, sesame, soybeans, etc. with its efficient multi-functional design, intelligent operating system and high-quality food-grade stainless steel materials. The equipment integrates multiple functions such as dephosphorization, dealkalization, dehydration, and decolorization to ensure that the oil meets national standards and improve product quality. Its low investment and high return make it an ideal choice for global oil producers. Choosing Gondor equipment will give you a stable and efficient production process and achieve long-term economic benefits.

If you are interested in the product or want to know more details, please fill in the inquiry box below, we will provide you with professional consultation and support!