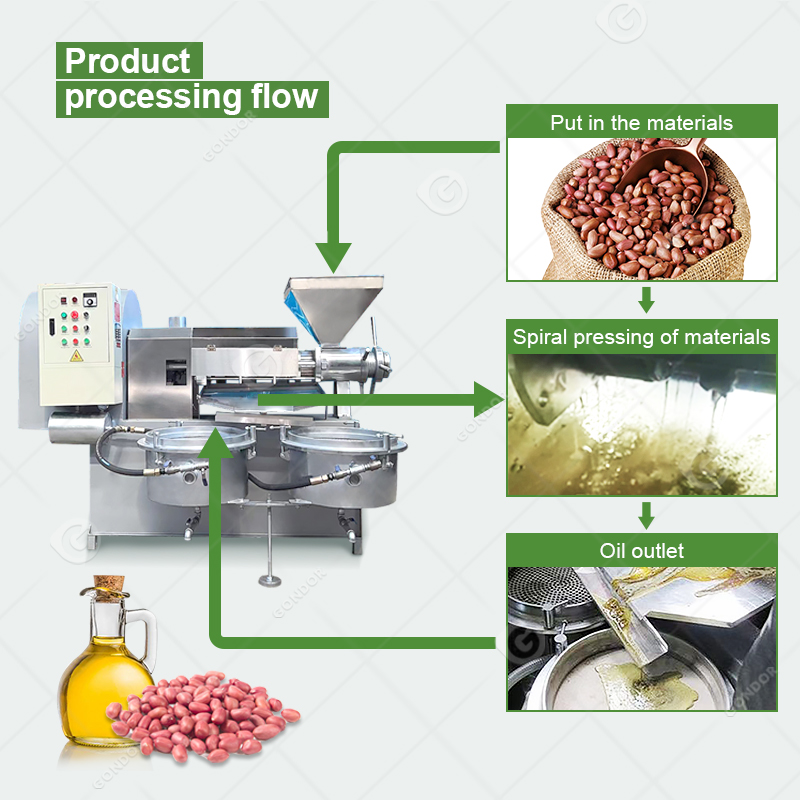

Screw press oil extraction machine is a device used to extract oil from oil crops. It is mainly composed of feeding, pressing, oil output and temperature regulation. When working, the crops enter the pressing chamber through the feeding system, and the raw materials are subjected to gradually increasing pressure under the push of the screw shaft. In this process, the oil is squeezed out and flows out through the gap of the pressing cage, while the remaining residue forms a cake and is discharged from the cake discharge device. Additionally, the screw oil press machine has the advantages of continuous operation, high production efficiency, high oil output rate and easy operation. It is not only suitable for a variety of oil crops, such as peanuts, soybeans, sesame, etc. And the oil it squeezes is of good quality, retaining the nutrients and flavor of the oil.

| Model | Handling capacity | Power of motor | Dimension | Weight |

| GD-SOPM60 | 30-40kg/h | 2.2kw | 1280*860*1210mm | 270kg |

| GD-SOPM70 | 60-70kg/h | 3kw | 1450*900*1300mm | 300kg |

| GD-SOPM80 | 80-120kg/h | 5.5kw | 1500*900*1620mm | 350kg |

| GD-SOPM100 | 200-250kg/h | 7.5kw | 1960*1250*1670mm | 850kg |

| GD-SOPM120 | 300-400kg/h | 15kw | 2500*1100*2300mm | 950kg |

| GD-SOPM130 | 100-200kg/h | 15kw | 2760*1100*1850mm | 1300kg |

| GD-SOPM160 | 400-500kg/h | 30kw | 2500*1600*2700mm | 1420kg |

Multiple Fields of Application of Gondor Spiral Oil Press Machine

- The cake after oil pressing is rich in nutrients such as protein and can be used to make feed.Feed Processing Industry

- Provide various oil raw materials required for food production.Food Processing Industry

- Some of the extracted oil may be used in the production of chemical products.Chemical Industry

- Secondary processing of waste generated by crops, such as rapeseed meal and peanut meal, to extract oil and realize resource recycling.Agricultural Field

- Used to press various oil crops, such as peanuts, rapeseed, sunflower, sesame seeds, etc., to produce edible oil.Edible Oil Processing Industry

- The kitchens of large restaurants can use screw oil presses to dehydrate and press food waste and refine it into industrial oil.Catering Industry

- Meet people’s needs for on-site processing and participation in the oil pressing process to ensure the quality and safety of the oil.Small Workshops

Gondor Screw Press Oil Extraction Extraordinary Quality Advantages

High Oil Yield

The screw of high-quality steel and advanced heat treatment technology are used, the oil yield is higher and the oil is clearer.

Large Production Volume

Strengthen the feeding system, increase the propulsion speed, effectively improve work efficiency, and meet the needs of large-scale production.

Automatic Temperature Control

Equipped with an electronic program control system, it can scientifically heat and automatically control the pressing temperature to adapt to the optimal processing temperature of different oils.

Automatic Oil Filter

Using the principle of air negative pressure, vacuum diversion technology, and built-in vacuum diverter, it can effectively separate oil and residue.

Safe and Convenient

The structure is exquisite and takes up less space; the transmission system adopts fully enclosed protection, and the design is safe and convenient.

Widely Applicable

It can be used for the pressing and oil production of various oil crops such as sesame, rapeseed, peanuts, cottonseed, soybeans, tea seeds, corn embryos, etc.

Gondor Screw Press Oil Extraction Machine – High-efficiency Oil Pressing Manufacturer

Want an efficient and high-quality oil pressing experience? Come to Gondor Machinery to order a screw press oil extraction machine! Our screw oil press machine has excellent performance, high oil yield and pure quality. Whether it is edible oil processing, catering industry or agricultural production, it is your ideal choice. Precise pressing, energy-saving and efficient, easy to operate. Choose Gondor to add momentum to your business, act now!